Replacement Levels (Typical Ranges)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Replacement Levels

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss the typical replacement levels for mineral admixtures in concrete. Why do you think it is important to consider these levels during concrete mix design?

I think it helps ensure that the concrete performs well, right?

Exactly! Proper replacement levels can improve workability, strength, and durability. Let’s look at some common admixtures and their recommended levels. First, can anyone tell me what Fly Ash is?

Isn't it a by-product of burning coal in power plants?

That’s right! Typically, Fly Ash can replace 15 to 35% of Portland cement in concrete, with allowances up to 50% for mass concrete. Remember, the more Fly Ash we use, the more sustainable our concrete mix becomes.

What about Silica Fume? How much can we use?

Silica Fume is highly reactive and is usually used at 5 to 10%. It contributes significantly to strength development but may require us to adjust water content in our mix.

And what about the others? Like GGBS?

Great question! GGBS can replace cement at levels of 30% to 70%, depending on the properties needed in the concrete. Now, who can summarize what we discussed regarding Fly Ash and Silica Fume?

Fly Ash replaces up to 35% of cement while Silica Fume is 5 to 10%.

Perfect! Let's review the benefits of using these mineral admixtures.

Practical Implications of Replacement Levels

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we’ve established the basic replacement levels, let's talk about the implications of these levels on concrete properties. Why might we want to increase the percentage of GGBS, for example?

It probably helps with durability and reduces heat of hydration.

That’s correct! Higher GGBS levels can lead to improved resistance against sulfate attack and better long-term durability. Do any of you recall how GGBS compares to Fly Ash in terms of replacement levels?

Fly Ash can go up to 50%, while GGBS goes between 30 and 70%.

Exactly! Higher levels of GGBS are particularly useful in structures exposed to aggressive environments. Also, don’t forget, using too high a replacement level can affect your setting time. Who can tell me about that?

Using Fly Ash can delay setting time, so we need to account for that in our planning.

Well said! Planning is essential when deciding on replacement levels. Let's move on to some specific case applications.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section details the recommended replacement percentages of various mineral admixtures such as Fly Ash, Silica Fume, GGBS, Metakaolin, and Rice Husk Ash. These ranges help in achieving optimized concrete performance.

Detailed

Replacement Levels (Typical Ranges)

In concrete mix design, the incorporation of mineral admixtures allows for enhancing the mechanical properties, durability, and sustainability of the final product. This section presents the typical replacement levels for a variety of mineral admixtures, providing guidance for engineers and practitioners in achieving optimal performance based on specific construction needs.

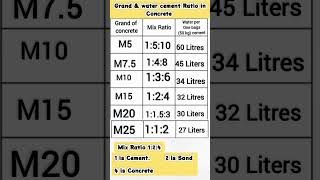

Typical Replacement Levels by Admixture:

- Fly Ash: 15–35% (up to 50% for mass concrete)

- Silica Fume: 5–10%

- GGBS: 30–70%

- Metakaolin: 5–15%

- Rice Husk Ash: 5–15%

These replacement levels are predicated on careful consideration of factors such as the desired properties of concrete, environmental conditions, and the specific characteristics of the mineral admixtures employed. The right proportions can lead to enhanced workability, reduced heat of hydration, improved long-term strength, and environmental sustainability.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Fly Ash Replacement Levels

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Admixture Cement Replacement (%)

Fly Ash 15–35% (up to 50% for mass concrete)

Detailed Explanation

Fly ash is typically used as a replacement for cement in concrete at levels ranging from 15% to 35%. In specific applications such as mass concrete, this replacement level can go up to 50%. This means that for every 100 grams of cement, you can substitute 15 to 35 grams with fly ash. The inclusion of fly ash can enhance the properties of concrete by improving workability and durability.

Examples & Analogies

Imagine making cookies where the recipe calls for flour. If you normally use 100 grams of flour, you might replace 15 to 35 grams of that flour with a different type of flour that is better at keeping the cookies soft and chewy. In mass concrete, it’s like using more of the special flour (up to half) to ensure the cookies (the concrete) stay fresher and don’t crumble.

Silica Fume Replacement Levels

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Silica Fume 5–10%

Detailed Explanation

Silica fume is typically used at lower replacement levels of about 5% to 10% of the cement in the concrete mix. This higher concentration of silica helps improve the strength and reduces permeability, making concrete more durable. A small amount can significantly improve the concrete's overall performance due to its high reactivity and fineness.

Examples & Analogies

Think of silica fume like the secret ingredient in a chocolate cake that makes it richer and more delicious. Even a small dose can enhance the entire flavor of the cake, just as 5%-10% of silica fume can substantially strengthen concrete.

GGBS Replacement Levels

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

GGBS 30–70%

Detailed Explanation

Granulated blast furnace slag (GGBS) can replace a larger portion of cement in the concrete mix, typically between 30% to 70%. This substantial replacement contributes to better long-term strength and durability due to its latent hydraulic properties. GGBS improves concrete’s resistance against various environmental factors, making it suitable for structures exposed to harsh conditions.

Examples & Analogies

Using GGBS is like reinforcing a house's foundation with additional strong materials. If you normally build a foundation with plain bricks (cement), adding 30% to 70% of reinforced bricks (GGBS) will make the foundation much stronger and better able to withstand storms or earthquakes.

Metakaolin Replacement Levels

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Metakaolin 5–15%

Detailed Explanation

Metakaolin is generally used at replacement levels of about 5% to 15% of cement content. This addition enhances the early strength of concrete and improves its resistance to chemical attacks, making it particularly useful in high-performance applications. Even a modest quantity can greatly contribute to both the structural integrity and durability of the concrete.

Examples & Analogies

think of metakaolin as a personal trainer for your concrete. Just as hiring a personal trainer may help you improve your physical fitness faster, adding 5%-15% metakaolin can help concrete gain strength quicker and resist wear and tear significantly better.

Rice Husk Ash Replacement Levels

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Rice Husk Ash 5–15%

Detailed Explanation

Rice husk ash can also replace a similar amount of cement, typically between 5% to 15%. This by-product can enhance the durability of concrete and improve its performance in aggressive environments. It acts as a pozzolanic material and can contribute to lowering the concrete's overall cost while providing environmental benefits by utilizing agricultural waste.

Examples & Analogies

Using rice husk ash is like choosing to include a nutritious vegetable in your favorite dish instead of more expensive ingredients. It’s cost-effective and boosts the dish’s (or concrete’s) nutritional value (or durability) without significantly affecting the flavor (or performance) of the final product.

Key Concepts

-

Replacement Levels: Specific percentages for substituting cement with mineral admixtures.

-

Optimization: Balancing performance and environmental benefits through appropriate replacement levels.

-

Specific Admixtures: Understanding the unique roles of Fly Ash, Silica Fume, GGBS, Metakaolin, and Rice Husk Ash.

Examples & Applications

Using Fly Ash at a 30% replacement level in a concrete mix improves workability and reduces carbon footprint.

GGBS at a 50% replacement level can enhance durability for structures exposed to harsh weather conditions.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Fly Ash is smart, from coal it’s part, up to fifty’s where it can start!

Stories

Imagine a builder, John, who wanted to reduce costs and improve sustainability. He discovered that by replacing 30% of his cement with Fly Ash, he not only saved money but also strengthened his concrete, leading to a successful project.

Memory Tools

FSGMR (Fly Ash, Silica Fume, GGBS, Metakaolin, Rice Husk Ash) - Remember these names for replacement levels!

Acronyms

GMR (GGBS, Metakaolin, Rice Husk) - Focus on high durability!

Flash Cards

Glossary

- Fly Ash

A by-product from the combustion of pulverized coal used in concrete as a pozzolanic material.

- Silica Fume

An ultra-fine by-product from silicon and ferrosilicon manufacturing, used to enhance concrete properties.

- GGBS

Ground Granulated Blast Furnace Slag, a by-product from steel manufacturing with latent hydraulic properties.

- Metakaolin

An aluminosilicate obtained from the calcination of concentrated kaolinite clay, acting as a highly reactive pozzolan.

- Rice Husk Ash

An ash produced from burning rice husks, containing high levels of amorphous silica.

Reference links

Supplementary resources to enhance your learning experience.