Ground Granulated Blast Furnace Slag (GGBS)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Origin and Production of GGBS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will discuss Ground Granulated Blast Furnace Slag, or GGBS. GGBS is produced by quenching molten iron slag in water or steam. What do you think happens during this quenching process?

I think it cools down rapidly to form a solid form.

Does it become a non-crystalline structure?

Exactly correct, Student_1 and Student_2! The rapid cooling leads to a glassy, granular product, making it very reactive when ground to a fine powder. This is crucial for its use in concrete.

Properties of GGBS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we know how GGBS is produced, let's explore its properties. What do you recall about its fineness compared to Ordinary Portland Cement?

I remember that it's similar or a bit finer than OPC.

And it's lighter in color, right?

Yes, excellent recall! GGBS is off-white or light gray, which can contribute to a more aesthetically pleasing concrete mix. Remember, its lower heat of hydration also makes it favorable for large projects.

Effects of GGBS on Concrete

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about the effects of GGBS on concrete. It enhances long-term strength and durability, but can you name some specific benefits?

It helps with resistance to sulfate attacks!

It also reduces alkali-silica reaction, right?

Exactly! GGBS increases durability by improving resistance to chemical attacks and reducing the risk of ASR. However, what should we keep in mind regarding early strength gain?

It takes longer to gain initial strength compared to OPC.

That's right! It may not provide the early strength as rapidly, but it compensates with enhanced properties over time.

Applications of GGBS in Concrete Mixes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s look at applications. Can anyone suggest where GGBS might be effectively employed in concrete?

In marine structures due to its resistance to chloride attacks!

What about large mass concrete works? It should be useful there too.

Exactly! GGBS is particularly beneficial in mass concrete applications to manage heat and in marine environments to reduce permeability. Well done, everyone!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Ground Granulated Blast Furnace Slag (GGBS) is produced from the rapid cooling of molten iron slag, making it an important mineral admixture in concrete. It significantly improves the long-term strength and durability of concrete while reducing the heat of hydration and the risk of alkali-silica reactions. GGBS contributes to enhanced resistance against sulfate and chloride attacks, making it ideal for various structural applications.

Detailed

Ground Granulated Blast Furnace Slag (GGBS)

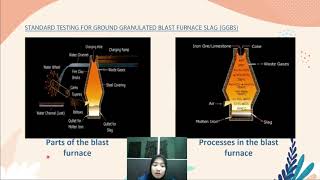

GGBS is produced by rapidly cooling molten iron slag—a by-product from steel manufacturing—using water or steam, which leads to the formation of a glassy, granular product that is subsequently dried and ground to a fine powder. This material is classified as a latent hydraulic admixture, meaning it has cementitious properties when activated in the presence of water and alkaline materials.

Properties

GGBS generally possesses a fineness similar to or slightly finer than Ordinary Portland Cement (OPC). Its off-white or light gray color and reduced heat of hydration compared to OPC contribute to its favorable characteristics in concrete applications.

Effects on Concrete

The use of GGBS in concrete offers several benefits:

1. Enhanced Long-term Strength and Durability: By contributing to the formation of additional calcium silicate hydrate (C-S-H), it refined the pore structure, resulting in denser concrete with improved mechanical properties over time.

2. Resistance to Chemical Attacks: It significantly enhances the concrete's ability to withstand sulfate and chloride attacks, which is critical in environments like coastal regions or areas with de-icing salts.

3. Reduction of Alkali-Silica Reaction (ASR): The incorporation of GGBS helps mitigate the risk of ASR, a deleterious reaction between alkali in cement and silica in aggregates that can lead to expansion and cracking.

4. Improved Aesthetic Qualities: Concrete containing GGBS can also achieve a better finish and appearance due to its smoother texture.

5. Slower Early Strength Gain: While GGBS may lead to slower early strength development, its benefits for long-term performance make it a valuable addition in many concrete applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Origin and Production

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

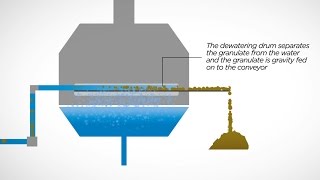

GGBS is produced by quenching molten iron slag (a by-product of steel manufacturing) in water or steam, which results in a glassy, granular product that is then dried and ground.

Detailed Explanation

GGBS originates from the steel manufacturing process. When iron is produced, slag is created as a by-product. This slag can be quite hot and is then rapidly cooled through a process of quenching in water or steam. This quick cooling leads to the formation of a granular and glassy material. After this, it is dried to remove any moisture and ground into a fine powder, making it suitable for use in concrete.

Examples & Analogies

Think of cooling molten lava. When lava flows into the ocean, it cools rapidly and forms glass-like rocks. Similarly, when molten slag is quenched, it forms a granular substance like GGBS, which, after grinding, can be used like a fine powder in concrete.

Properties

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Latent hydraulic (requires activation)

- Fineness: Similar or slightly finer than OPC

- Color: Off-white or light gray

- Lower heat of hydration than OPC

Detailed Explanation

GGBS is categorized as a latent hydraulic material, meaning that it does not exhibit cementitious properties on its own and requires activation, typically through the presence of alkaline materials, like calcium hydroxide in ordinary Portland cement (OPC). Its fineness is comparable to, or slightly finer than, ordinary Portland cement, and it typically has a light color, ranging from off-white to light gray. One of the critical properties of GGBS is that it generates lower heat during hydration compared to OPC, making it favorable for large-scale concrete applications.

Examples & Analogies

Imagine GGBS as a team player who needs the right conditions to shine. Just as a person may perform best in a supportive environment, GGBS needs activation to develop its properties effectively. Its ability to generate lower heat during reactions is like a person remaining calm in a stressful situation, helping everyone around them stay cooler.

Effects on Concrete

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Enhances long-term strength and durability

- Improves resistance to sulfate and chloride attack

- Reduces alkali-silica reaction (ASR)

- Contributes to better finish and appearance

- Slower early strength gain

Detailed Explanation

Incorporating GGBS into concrete has several beneficial effects. It significantly improves the long-term strength and durability of concrete, making it more resistant to harmful compounds like sulfates and chlorides, which can cause deterioration. GGBS also helps to mitigate alkali-silica reactions (ASR), which is a form of concrete expansion that can lead to cracking. Additionally, concrete with GGBS often has a smoother finish and better appearance. However, it's important to note that concrete made with GGBS tends to achieve its strength more slowly in the initial curing phase compared to concrete made with solely Portland cement.

Examples & Analogies

Using GGBS in concrete is like planting a young tree. Initially, the tree may seem small (early strength gain), but over time, as it grows, it becomes strong and resilient (enhanced long-term strength and durability). Just as a good tree can withstand storms due to its robust structure, concrete with GGBS can resist the destructive forces of chemical attacks and environmental challenges.

Key Concepts

-

Production Process: GGBS is formed by quenching molten iron slag, making it reactive and useful in concrete.

-

Properties: GGBS is a latent hydraulic material that enhances concrete performance.

-

Long-term Benefits: Use of GGBS improves concrete strength, durability, and resistance to aggressive environments.

Examples & Applications

In precast concrete products, GGBS enhances surface finish and structural performance.

Marine structures utilize GGBS concrete to withstand harsh conditions from saltwater exposure.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

GGBS cools the slag, a strong concrete brag.

Stories

Once upon a time, iron slag took a plunge into water, transforming into a lifesaver for concrete, giving it strength like never before!

Memory Tools

GGBS - Great Growth in Building Strength.

Acronyms

GGBS - Granulated Glassy Blast Slag.

Flash Cards

Glossary

- GGBS

Ground Granulated Blast Furnace Slag, a by-product of steel manufacturing used as a mineral admixture in concrete.

- Latent Hydraulic

A material that shows cementitious properties when activated by water and alkaline substances.

- Calcium Silicate Hydrate (CSH)

The primary compound responsible for the strength and durability of concrete.

- AlkaliSilica Reaction (ASR)

A chemical reaction between alkali in cement and reactive silica in aggregates leading to expansion and cracking.

Reference links

Supplementary resources to enhance your learning experience.