Metakaolin

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Metakaolin

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Good morning, everyone! Today, we're diving into Metakaolin, a fascinating mineral admixture in concrete. Can anyone tell me how Metakaolin is produced?

Is it from kaolinite clay? I remember something about that during my readings.

Exactly! Metakaolin is produced by heating kaolinite clay to about 600 to 800 degrees Celsius. This heating process, known as calcination, transforms the crystalline structure into an amorphous one. What do you think are the advantages of this transformation?

I think it makes the Metakaolin more reactive as a pozzolan.

Great point! This increased reactivity enhances its performance in concrete. Remember, when we talk about pozzolans, we're referring to materials that can react chemically with calcium hydroxide to form additional C-S-H, the glue that holds concrete together.

So, Metakaolin can improve concrete strength, right?

Absolutely! In essence, Metakaolin helps increase both early and long-term concrete strength while reducing its permeability. Let's summarize: Metakaolin is derived from kaolinite clay through calcination, making it a highly reactive pozzolan that enhances concrete's structural integrity.

Properties and Effects of Metakaolin

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand what Metakaolin is, let’s explore its properties. What are some key properties that you think make Metakaolin useful in concrete?

It must have a high silica content, right?

Correct! Metakaolin is rich in silicon dioxide (SiO2) and aluminum oxide (Al2O3). This composition contributes to its pozzolanic activity. How does higher reactivity impact concrete?

It probably enhances strength.

Yes! It increases both the early and long-term strength of concrete. Plus, it reduces porosity and permeability, making the concrete more durable. Can anyone summarize the benefits of using Metakaolin in a sentence?

It improves strength, reduces permeability, and enhances surface finish in concrete!

Excellent summary! Always remember these points because they highlight why Metakaolin is a top choice for high-performance concrete.

Applications of Metakaolin in Concrete

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To wrap up our discussion on Metakaolin, let's consider its applications. Where do you think Metakaolin is mainly used in the concrete industry?

Maybe in high-performance concrete?

Exactly! High-performance concrete, or HPC, utilizes Metakaolin because of its superior properties. Can anyone think of other applications where high strength and durability are required?

What about in structures exposed to aggressive environments, like marine applications?

Spot on! The enhanced durability and resistance to alkali-silica reactions make Metakaolin valuable in such scenarios. So, in summation, Metakaolin is not just about improved strength; it's about ensuring concrete can withstand various tough conditions.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores Metakaolin's origin through the calcination of kaolinite clay, its unique properties as a reactive pozzolan, and its significant effects on concrete, including increased strength and reduced permeability, making it vital in high-performance concrete applications.

Detailed

Metakaolin

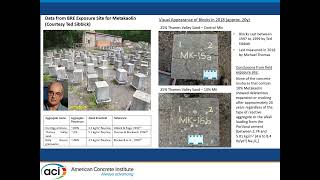

Metakaolin is produced by the calcination of kaolinite clay, typically at temperatures between 600°C and 800°C. This process transforms the clay into an amorphous aluminosilicate, lending it unique properties that are beneficial in concrete. As a highly reactive pozzolan, Metakaolin significantly enhances both early and long-term strength of concrete while reducing porosity and permeability. It also improves the concrete's resistance to alkali-silica reactions (ASR) and contributes to a superior surface finish. Due to these properties, Metakaolin is especially effective in high-performance concrete (HPC), where strength and durability are paramount.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Origin and Production

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Metakaolin is obtained by the calcination of purified kaolinite clay at temperatures between 600–800°C, converting it into an amorphous aluminosilicate.

Detailed Explanation

Metakaolin is produced by heating kaolinite clay, a natural mineral, at high temperatures (600-800 degrees Celsius). This process is known as calcination, and during it, the crystalline structure of the clay transforms, resulting in metakaolin's unique amorphous form. This means that metakaolin lacks a defined crystal structure, which makes it a highly reactive pozzolanic material.

Examples & Analogies

Think of cooking a cake. When you bake a cake, you change its texture and properties by applying heat. Similarly, metakaolin undergoes a transformation when heated, changing its properties and making it useful as a concrete additive.

Properties

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

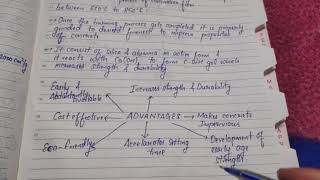

Properties

- Highly reactive pozzolan

- SiO₂ and Al₂O₃ rich

- Specific surface: High (depends on processing)

Detailed Explanation

Metakaolin is recognized as a highly reactive pozzolan, which means it can react with calcium hydroxide in the presence of water to enhance the concrete's strength. Its chemical composition is rich in silicon dioxide (SiO₂) and aluminum oxide (Al₂O₃), which are crucial for the pozzolanic reaction. The specific surface area of metakaolin is also high, meaning that the finer the metakaolin particles are, the more surface area they have to react, leading to improved performance in concrete.

Examples & Analogies

Imagine a sponge. A sponge with a larger surface area can soak up more water than a flat piece of cloth. Similarly, metakaolin's larger surface area allows for better interaction with water and calcium hydroxide, making the concrete stronger.

Effects on Concrete

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Effects on Concrete

- Increases early and long-term strength

- Reduces porosity and permeability

- Enhances resistance to ASR

- Improves surface finish

- Effective in high-performance concrete (HPC)

Detailed Explanation

The inclusion of metakaolin in concrete leads to several beneficial effects. It significantly increases both the early strength and the long-term strength of concrete, meaning that structures can achieve their strength requirements more quickly. Metakaolin also contributes to reducing porosity and permeability, which helps prevent water and harmful substances from penetrating the concrete. This reduction is especially important for resisting alkali-silica reaction (ASR), a detrimental reaction that can occur in concrete. Furthermore, metakaolin improves the surface finish of concrete, making it more aesthetically pleasing. Its effectiveness in high-performance concrete (HPC) highlights its importance in modern construction applications.

Examples & Analogies

Consider a strong fortress compared to a regular wall. The fortress not only stands tall but also has fewer cracks and holes, making it impenetrable. Similarly, concrete with metakaolin acts like a fortress against water and other harmful elements, providing better durability and strength.

Key Concepts

-

Production: Metakaolin is produced through the calcination of kaolinite clay.

-

Reactivity: It is a highly reactive pozzolan that enhances concrete performance.

-

Strength Improvement: Metakaolin increases both early and long-term strength in concrete.

-

Reduced Permeability: It lowers the permeability of concrete, making structures more durable.

-

Resistance to ASR: Metakaolin enhances resistance to alkali-silica reaction, preventing damage in concrete.

Examples & Applications

In high-performance concrete (HPC), Metakaolin is often used to achieve compressive strengths exceeding 70 MPa.

Structures exposed to seawater, such as marine foundations, benefit from the reduced permeability offered by Metakaolin.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When kaolin gets hot, Metakaolin is what we've got; stronger concrete, no doubt, that’s what it’s all about.

Stories

Once there was a clay called kaolinite. It dreamt of being strong. With a fiery transformation, it became Metakaolin, a hero that could enhance concrete and help it last longer than ever.

Memory Tools

PRISM: Production, Reactivity, Improvement of Strength, Surface finish, Metakaolin.

Acronyms

MAP - Metakaolin's Amazing Properties

Strength

Durability

Resistance to ASR.

Flash Cards

Glossary

- Metakaolin

A highly reactive pozzolan obtained from the calcination of kaolinite clay, enhancing the performance of concrete.

- Pozzolan

A material that reacts with calcium hydroxide in the presence of water to form additional calcium silicate hydrate.

- CSH

Calcium silicate hydrate, the main binding phase in concrete responsible for its strength.

- Permeability

The ability of a material to allow fluids to pass through it, with lower permeability indicating better durability.

- AlkaliSilica Reaction (ASR)

A reaction between reactive silica in aggregates and alkalis in cement that can cause expansion and cracking in concrete.

Reference links

Supplementary resources to enhance your learning experience.