Key Considerations

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Water-Cementitious Ratio

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about the water-cementitious ratio, or w/cm, and why it’s crucial when using mineral admixtures in concrete mixes.

What happens if we don’t adjust the w/cm ratio correctly?

If it’s too high, we can get weak concrete that's more porous. Reducing it can enhance strength but might make the mix too dry and hard to work with.

So, how do we determine the right w/cm?

Good question! We base it on the fineness and absorption characteristics of the admixtures. Remember, a common guideline is keeping w/cm around 0.4 to 0.5 for regular mixes.

Can we use a mnemonic to remember this? Like 'Water Weight Matters'?

That's perfect! 'Water Weight Matters' can remind you to balance the water with cement and admixture amounts for optimal performance.

Curing Duration

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s explore curing duration. Why do you think it matters when we use mineral admixtures?

Is it because it helps the admixtures react properly?

Exactly! Longer curing enhances the pozzolanic reactions, improving strength and durability. A good rule is to aim for a minimum of seven days of curing.

What if we can't cure for that long?

In such cases, using curing compounds or moisture-retentive covers can help, but the best practice is still to prioritize good curing.

It's like giving the concrete a solid start in life!

You got it! Good curing is vital for achieving concrete’s potential, especially with admixtures.

Workability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's move on to workability. Why is this aspect so crucial when using mineral admixtures?

If it’s not workable, the concrete will be hard to mix and place!

Right! Some additives, like silica fume, may reduce workability. We may need to add superplasticizers to achieve the desired slump.

So, is there a way to remember this?

Sure! Think 'Fluidity First'—always ensure your mix flows well before focusing on other properties.

Fluidity First—got it!

Great! Always prioritize workability in your designs.

Setting Time

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss setting time, which can vary significantly with different admixtures.

Like how fly ash can extend setting time?

Exactly! Fly ash tends to delay setting, while metakaolin can speed it up. How does this information help you in planning a project?

We need to consider these factors for scheduling our work.

That’s correct! It’s essential to align our schedule with the expected setting times for different mixes.

Can we use a rhyme to remember this?

Sure! How about 'Ash delays, while Kaolin plays'? This helps you recall the effects of each!

Summary of Key Considerations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s summarize what we’ve talked about. What are the key considerations for mix design with mineral admixtures?

We talked about adjusting the water-cement ratio.

And the importance of curing duration for better pozzolanic reaction!

Workability is another factor—keeping it fluid is vital!

And we must note how different admixtures affect setting times.

Fantastic recall! Always remember these key points while designing for optimal performance.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, the critical considerations for designing concrete mixes containing mineral admixtures are discussed, including the importance of adjusting the water-cement ratio, curing duration, workability, and setting time to achieve the desired strength and durability in the final product.

Detailed

Key Considerations in Mix Design with Mineral Admixtures

The section outlines essential guidelines for effectively incorporating mineral admixtures into concrete mixes. Key factors include:

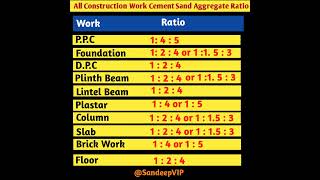

- Water-Cementitious Ratio (w/cm): This must be adjusted based on the fineness and absorption characteristics of the admixtures used. The right w/cm ratio is vital for achieving desired strength and durability.

- Curing Duration: Prolonged curing enhances pozzolanic activity, which positively impacts the concrete’s mechanical and durability properties.

- Workability: The use of mineral admixtures can affect workability, necessitating the use of additional admixtures to attain the desired slump for ease of placement and compaction.

- Setting Time: The setting time can be extended when using certain admixtures like fly ash or GGBS. In contrast, metakaolin may accelerate the setting time.

By carefully examining these considerations, engineers can optimize the performance criteria of concrete mixes, leading to better durability and overall project efficiency.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Water-Cementitious Ratio (w/cm)

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Should be adjusted based on fineness and absorption.

Detailed Explanation

The water-cementitious ratio is a crucial factor in concrete mix design. It refers to the ratio of the mass of water to the mass of cement and other cementitious materials in the mix. This ratio should be adjusted according to the fineness of the materials and their absorption qualities. Finer materials tend to require more water due to their higher surface area, which can absorb more water. Therefore, understanding these characteristics allows for precise control over the concrete's strength and durability.

Examples & Analogies

Think of making oatmeal. If you use finely ground oats (finer), you'll need more water to achieve the desired consistency compared to using coarser oats. Similarly, in concrete, finer particles require a careful balance of water to ensure the mix has the right workability.

Curing Duration

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Longer curing improves pozzolanic benefits.

Detailed Explanation

Curing is the process of maintaining adequate moisture, temperature, and time to allow the concrete to achieve its desired strength and durability. With mineral admixtures, longer curing periods can significantly enhance the pozzolanic reactions, which are crucial for developing higher long-term strength and durability. This is because the pozzolanic materials continue to react over time, producing additional cement-like compounds that contribute to the overall integrity of the concrete.

Examples & Analogies

Consider how bread rises when you leave it to rise properly; the longer you allow it to rise, the better the texture and flavor. Similarly, giving your concrete the time it needs to cure allows it to reach its full potential in terms of strength and durability.

Workability

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

May need admixtures to achieve desired slump.

Detailed Explanation

Workability refers to how easily a fresh concrete mix can be handled, placed, and finished. With the introduction of mineral admixtures, the workability can change, potentially making the mix stiffer or harder to work with. To ensure a desired level of slump (the measure of consistency and fluidity), additional chemical admixtures like plasticizers or superplasticizers may be needed. This allows for easier placement without compromising the strength or durability of the concrete.

Examples & Analogies

Imagine trying to spread thick peanut butter on bread. It can be stiff and hard to manage. However, if you add a bit of honey to thin it out (like using a superplasticizer), you can spread it much more easily without it tearing the bread. This is similar to modifying concrete for better workability.

Setting Time

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Extended with fly ash or GGBS; accelerated with metakaolin.

Detailed Explanation

The setting time of concrete is the period it takes for the concrete to harden sufficiently to support weight and be workable. Using mineral admixtures like fly ash and Ground Granulated Blast Furnace Slag (GGBS) can extend the setting time because these materials react more slowly than traditional cement. Conversely, using metakaolin can speed up the setting time due to its highly reactive nature. Understanding how each admixture influences setting time helps in planning construction schedules effectively.

Examples & Analogies

Think of baking a cake. Some recipes (like those with more sugar) take longer to bake because they are dense, while others with lighter ingredients cook faster. In concrete, the choice of mineral admixture influences how quickly the mix sets, which can impact the timing of construction activities.

Key Concepts

-

Water-Cement Ratio: The critical ratio that affects the strength and workability of concrete.

-

Curing Duration: The time concrete should be cured for effective hydration and strength gain.

-

Workability: The ease of handling and placing concrete, influenced by material choice and proportions.

-

Setting Time: The time it takes for concrete to transition from a liquid to a solid state.

Examples & Applications

Using a water-cement ratio of 0.45 leads to an ideal balance of strength and workability in concrete mixes with mineral admixtures.

Extending the curing duration for a concrete mix with fly ash allows for greater strength development due to enhanced pozzolanic activity.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When water’s in with ratio right, your concrete gains both strength and might.

Stories

Imagine a concrete child growing strong; with enough water and care, it thrives along.

Memory Tools

W-C-C-W-S (Water-Cement-Cure-Workability-Setting) helps you remember the key considerations.

Acronyms

C-W-W-S (Curing-Water-Workability-Setting) as a guide for what to keep in mind for strong mixtures.

Flash Cards

Glossary

- WaterCementitious Ratio

The ratio of the weight of water to the weight of cementitious materials in a concrete mix.

- Curing Duration

The period during which concrete should be kept moist to ensure proper hydration.

- Workability

The ease with which concrete can be mixed, placed, compacted, and finished.

- Setting Time

The time required for fresh concrete to harden to a point where it can sustain some load.

Reference links

Supplementary resources to enhance your learning experience.