Ductile Detailing as per IS 13920:2016

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Ductile Detailing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we are going to explore the importance of ductile detailing in reinforced concrete structures. Ductility is critical during seismic events to prevent sudden and brittle failures. Can anyone tell me why ductility is important?

It helps structures absorb seismic forces without collapsing!

Exactly! Ductility allows the structure to undergo large deformations while retaining strength. This is essential for energy dissipation during an earthquake. What else can ductility do?

It provides early warning through large deformations!

That's right! You can think of ductility as a built-in warning system for engineers and occupants. A good mnemonic to remember could be 'DAMP' – Ductility Allows Major Protection. Let's move on to the detailing requirements.

Beam and Column Requirements

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's look at the key detailing requirements for beams and columns. Can anyone tell me what the minimum tension steel requirement for beams is?

It should be at least 2.5 times the balancing steel!

Correct! Additionally, the maximum steel content should not exceed 4% of the cross-section. Why do you think these limits are in place?

To ensure the beams can flex without becoming too rigid?

Precisely! It’s important to maintain flexibility. Speaking of which, what is the role of closely spaced stirrups in beams?

They provide shear reinforcement!

Absolutely! A helpful acronym to remember is 'SHEAR' – Stirrups Help Ensure Adequate Resistance. Great job, everyone!

Beam-Column Joints and Shear Walls

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about the detailing of beam-column joints. What type of reinforcement is required at these critical junctions?

Closed hoops for confinement!

Correct! Closed hoops are critical for enhancing strength in all directions. Why do you think this is particularly important during an earthquake?

They help resist the shear forces acting at the joint!

Exactly! And we also have special requirements for shear walls. What must we ensure about the boundary elements?

They need special detailing in edge zones!

Well done! Boundary elements are crucial for performance. To remember the importance of boundary elements, think of 'BAND' - Boundary And New Detailing! Great contributions today.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Ductile detailing per IS 13920:2016 is crucial for transforming reinforced concrete structures into resilient forms capable of absorbing and dissipating seismic forces. The pivotal detailing requirements for various structural components, including beams and columns, are emphasized to prevent sudden failures during earthquakes, especially in seismic zones III to V.

Detailed

Ductile Detailing as per IS 13920:2016

IS 13920:2016 provides detailed guidelines for ductile detailing of reinforced concrete (RC) structures that are expected to withstand seismic forces. The primary objective of ductile detailing is to enable these structures to deform sufficiently under seismic loads while maintaining integrity and avoiding brittle failure.

Applicable Structures

Ductile detailing guidelines apply particularly to structures in Seismic Zones III, IV, and V, along with those in Zone II that exhibit special importance or structural irregularities.

Key Detailing Requirements

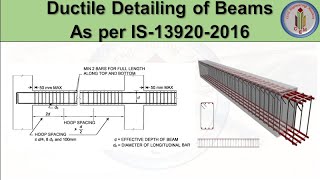

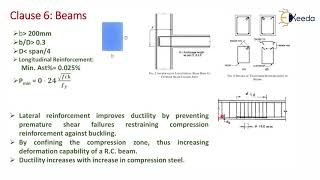

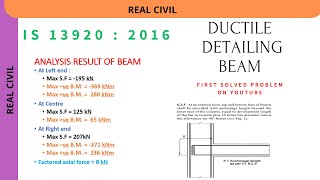

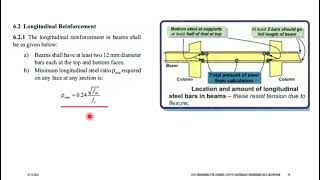

a) Beams:

- Minimum and Maximum Reinforcement:

- The amount of tension steel should be at least 2.5 times the balancing steel.

- Maximum steel content is limited to 4% of the cross-section.

- Anchorage Length:

- Must extend beyond critical sections to ensure adequate bonding.

- Shear Reinforcement:

- Stirrups should be closely spaced in potential plastic hinge zones (minimum 2-legged with spacing ≤ d/4).

- Flexural Overstrength:

- Adopt a strong column–weak beam convention to ensure that beams yield before columns.

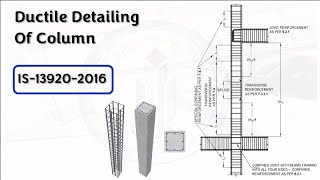

b) Columns:

- Transverse Reinforcement:

- Provide confining hoops or ties at closely spaced intervals near beam-column joints.

- Lap Splices:

- Should only be placed in the central half of the column, avoiding positions close to joints.

- Minimum Dimension:

- The cross-section of columns must be at least 200 mm.

- Confinement Reinforcement:

- Essential for plastic hinge zones and potential collapse regions.

c) Beam-Column Joints:

- Closed Hoops:

- Required for confinement in all directions at joints to enhance strength and ductility.

- Shear Strength Check:

- Should be performed based on moment-shear interaction principles.

d) Shear Walls:

- Boundary Elements:

- Special detailing requirements in edge zones to enhance performance during seismic loading.

- Horizontal & Vertical Reinforcement:

- Must be spaced and anchored appropriately.

- Confinement in Ends:

- Required for ensuring sufficient ductility, particularly in rocking or flexural actions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Applicable Structures

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Structures in Seismic Zones III, IV, and V

Structures in Zone II with importance or irregularity

Detailed Explanation

This chunk emphasizes the types of structures that are subject to ductile detailing as per IS 13920. Specifically, it notes that structures located in Seismic Zones III, IV, and V are required to follow these guidelines due to the higher risk of significant seismic activity. Additionally, even structures in Zone II are included if they possess characteristics of importance (such as critical facilities) or irregularities in design that might make them more vulnerable to seismic forces.

Examples & Analogies

Imagine a city in a region prone to hurricanes. Buildings in the most vulnerable areas (like near the coast) need to have stronger materials and designs to withstand high winds. Similarly, in earthquake-prone areas, structures in the hardest-hit zones need to be built with extra care to ensure safety.

Key Detailing Requirements for Beams

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

a) Beams:

- Minimum and Maximum Reinforcement:

- Tension steel ≥ 2.5 times balancing steel.

- Max steel ≤ 4% of cross-section.

- Anchorage Length: Sufficient development length beyond critical section.

- Shear Reinforcement: Closely spaced stirrups in potential plastic hinge zones (minimum 2-legged, spacing ≤ d/4).

- Flexural Overstrength: Strong column–weak beam concept to ensure beam yields before column.

Detailed Explanation

Ductile detailing for beams involves several critical aspects to ensure they perform well under seismic loads. The specification for minimum and maximum reinforcement is crucial: it helps maintain the structural integrity during earthquakes. The requirement that tension steel must be at least 2.5 times the balancing steel means that there is enough capacity to absorb forces. The maximum reinforcement limit is set to prevent overly rigid sections which can lead to sudden failure. Anchorage length ensures that reinforcements are adequately fixed, while closely spaced stirrups provide additional strength in areas where plastic hinges are expected. The concept of strong column–weak beam ensures that, during an earthquake, the beam will yield before the column, allowing for a more controlled and ductile response.

Examples & Analogies

Think of a bicycle and its frame. The frame (like the column) needs to be strong enough to support the rider but also flexible enough not to snap under stress. If the handlebars (the beam) bend slightly when riding on an uneven path, it can absorb the shocks rather than the frame breaking.

Key Detailing Requirements for Columns

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

b) Columns:

- Transverse Reinforcement: Confining hoops or ties at close spacing near beam-column joints.

- Lap Splices: Placed only in the central half, not near joints.

- Minimum Dimension: Column cross-section ≥ 200 mm.

- Confinement Reinforcement: For plastic hinge zones and potential collapse regions.

Detailed Explanation

Columns play a vital role in the structural system, and their detailing guidelines ensure they maintain strength during seismic events. Transverse reinforcement, such as hoops and ties, is implemented at locations where beams connect to columns. This feature increases resilience, particularly near critical joint areas. The restriction on lap splices to central zones avoids weakness near joints that could lead to failure during movement. The minimum dimension requirement ensures columns have sufficient mass and strength to provide critical support in seismic resistance. Additionally, confinement reinforcement in critical regions helps to prevent local failures that could lead to structural collapse.

Examples & Analogies

Think of a tree trunk during a storm. A robust trunk (like a well-designed column) supports the branches while also allowing for some bending. If the trunk is too thin or improperly reinforced, it may snap under pressure, similar to how poorly designed columns can fail under seismic loads.

Key Detailing Requirements for Beam-Column Joints

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

c) Beam-Column Joints:

- Closed Hoops: For confinement in all directions.

- Shear Strength Check: Based on moment–shear interaction.

Detailed Explanation

Beam-column joints are critical areas that must be designed with special attention as they connect beams and columns. The use of closed hoops enhances the confinement of the concrete, allowing it to handle stresses from all directions. This is especially important during seismic loading, where forces can act unpredictably. Additionally, performing a shear strength check helps ensure that the joint can to withstand the combined forces of shear and moment during an earthquake, preventing potential failures.

Examples & Analogies

Imagine a bridge's support pillar connecting to the road deck. Just like the joints need strong reinforcements to handle the forces of traffic, beam-column joints must be heavily reinforced to manage the loads of a building during an earthquake.

Key Detailing Requirements for Shear Walls

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

d) Shear Walls:

- Boundary Elements: Special detailing in edge zones.

- Horizontal & Vertical Reinforcement: Proper spacing and anchorage.

- Confinement in Ends: For ductility in rocking or flexural action.

Detailed Explanation

Shear walls are essential components of buildings, particularly in earthquake-prone areas. Their detailing requires special attention to boundary elements to ensure adequate strength and stability. Both horizontal and vertical reinforcements need precise spacing and anchoring to effectively transfer loads during an earthquake. Proper confinement at the ends of shear walls is critical, as it allows the wall to flex in a controlled manner during seismic activity, enhancing ductility and preventing catastrophic failure.

Examples & Analogies

Think of a high-rise building as a tall tree. A shear wall acts like the tree’s base; a strong and flexible base allows the tree to sway in the wind without toppling over. Proper reinforcement ensures the tree doesn’t break but bends safely.

Key Concepts

-

Ductility: The capacity of a structure to deform without sudden failure under seismic loads.

-

Beam-Column Joint: A critical structural joint for which special detailing is required to maintain integrity during seismic events.

-

Shear Walls: Vertical structures designed to resist lateral forces that must be carefully detailed for greater strength and ductility.

Examples & Applications

In regions like Seismic Zone V, applying minimum reinforcement as specified in IS 13920 ensures beam safety against earthquakes.

In a recent seismic event, structures with enhanced ductile detailing performed better, highlighting the importance of adhering to guidelines.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In the quake's fierce might, don't lose sight, ductility protects, keeping structures right.

Stories

Imagine a building standing tall as an earthquake shakes the ground. Its beams flex and sway but don’t snap; they heroically bend due to their ductile detailing!

Memory Tools

Remember BECOME for Beam details: B for Balancing Steel, E for Edge stirrups, C for Confinement hoops, O for Overstrength concept, M for Minimum size, E for Elastic behavior.

Acronyms

DAMP - Ductility Allows Major Protection.

Flash Cards

Glossary

- Ductility

The ability of a material to undergo large deformations without fracturing.

- Reinforced Concrete (RC)

Concrete that is reinforced with steel bars (rebar) to improve tensile strength.

- Seismic Forces

Forces that occur during an earthquake, requiring specific design considerations.

- Plastic Hinges

Regions in a structure where significant plastic deformation occurs under loads.

- Flexural Overstrength

A design philosophy where elements are designed to yield in a controlled manner to prevent collapse.

Reference links

Supplementary resources to enhance your learning experience.