Sources of Ductility in RC Structures

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Material Ductility

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's begin our discussion on the first source of ductility: material ductility. What do you think is the importance of using high-quality steel and concrete in a structure?

I think it helps the structure to bend without breaking, right?

Exactly! High-quality steel can stretch and deform without fracturing, while properly confined concrete helps maintain strength during deformation. Together, they enhance the overall ductility.

So, if we use poor quality materials, it might lead to brittle failure?

Correct! Poor materials often lead to sudden failures that can be catastrophic. Now, to remember this, think of 'SCCC' — Strong Concrete and Careful Classification.

Can you explain more about confined concrete?

Sure! Confined concrete, reinforced with steel, can absorb more energy, which is critical in seismic zones. Let’s keep reinforcing these ideas!

What happens if concrete isn’t confined properly?

It may lead to a lack of support under loads, risking the structure's integrity. To summarize, using high-quality materials is essential for enhancing ductility.

Structural Ductility

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

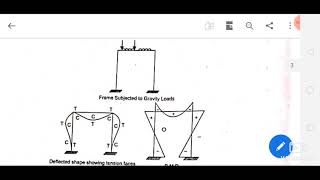

Now, let’s move to our second source of ductility: structural ductility. Can anyone suggest how we can enhance ductility through structural design?

Maybe by designing beams and columns to work together better?

Absolutely! Properly detailed connections between beams and columns allow for easy transfer of loads, ensuring each element can deform effectively. Think of this process as 'D-Joint', where D stands for Design, connected through joints.

What else can affect the ductility?

Great question! Over-reinforcement in beams can lead to brittle failure. It's vital to maintain a proper balance between reinforcement and concrete.

How can we ensure that detailed connections hold during a quake?

Through effective detailing and using ductile materials near potential plastic hinge zones. Don’t forget that attention to these details is key for stability!

In one word, what’s the key takeaway from structural ductility?

Integration! The structural elements must work together harmoniously to ensure effective energy dissipation.

System Ductility

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's discuss system ductility. What role does redundancy play in enhancing ductility?

Redundancy means having extra support in case one part fails?

Exactly! Redundancy allows other parts of the structure to take on the loads when one element is compromised, preventing overall failure.

Can you give an example of what that would look like?

Sure! Think of a bridge with multiple support beams. If one fails, the others help distribute the load, minimizing risk. Remember: 'R-Load', where R stands for Redundancy.

What if the design isn’t symmetrical?

Good inquiry! Asymmetrical designs may introduce torsional forces which can impact ductility. It’s critical to ensure symmetry in the overall configuration.

So in summary, redundancy and careful layout enhance the ductility?

Correct! A well-designed system not only provides strength but also flexibility during seismic events.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Ductility in reinforced concrete (RC) structures is vital for ensuring earthquake resilience. This section identifies three essential sources of ductility: material ductility, achieved by using quality steel and well-confined concrete; structural ductility, derived from effective design practices; and system ductility, which involves strategic structural configuration and redundancy.

Detailed

Sources of Ductility in RC Structures

Ductility is crucial for the performance of reinforced concrete (RC) structures during seismic events. It allows structures to deform significantly without losing strength, thereby avoiding sudden failures. In this section, we discuss three main sources of ductility:

1. Material Ductility

- Utilizes high-quality, tensile steel that can withstand deformation and properly confined concrete that maintains its integrity under stress.

2. Structural Ductility

- Achieved through thoughtful design and detailing of elements within the structure, ensuring that beams, columns, and joints are capable of deforming suitably under load.

3. System Ductility

- Focuses on the overall layout and composition of the structural system, promoting redundancy and ductile configurations that allow for energy absorption and reduced vulnerability during earthquakes.

These sources contribute significantly to the reliability and safety of RC structures in seismic zones, making it imperative for engineers to incorporate these aspects during design.

Youtube Videos

![Ductile Design and Seismic Detailing in RC Buildings [Ep 1.2]](https://img.youtube.com/vi/gTXVXQ-x8Yk/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Material Ductility

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Material Ductility: Use of high-quality steel and properly confined concrete.

Detailed Explanation

Material ductility refers to the ability of the materials used in a structure, such as steel and concrete, to deform under stress without failing. High-quality steel has a higher yield strength and better ductility characteristics, allowing it to absorb energy during seismic events without fracturing. Properly confined concrete also contributes to ductility by redistributing stresses and avoiding brittle failure.

Examples & Analogies

Think of a high-quality rubber band compared to a brittle plastic string. A rubber band can stretch significantly before it breaks, similar to how ductile materials can deform without losing strength, whereas the plastic string will snap if pulled too hard. This ability of materials to stretch and bend under pressure helps structures withstand earthquakes.

Structural Ductility

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Structural Ductility: Achieved by proper design and detailing of structural members.

Detailed Explanation

Structural ductility is achieved through careful design and detailing of structural components like beams and columns. It involves strategies like ensuring appropriate load distribution and detailing junctions where two or more members meet. This helps to create a structure that is capable of undergoing deformations without collapsing, allowing it to better absorb seismic energy.

Examples & Analogies

Imagine a well-designed bridge compared to a poorly designed one. The well-designed bridge has flexible joints and connections, allowing it to sway slightly during strong winds or earthquakes, much like how a tree bends in the wind without breaking. This flexibility is what we mean by structural ductility.

System Ductility

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

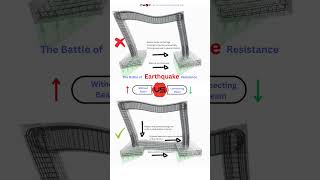

- System Ductility: Ductile configuration and redundancy in structural layout.

Detailed Explanation

System ductility refers to the overall configuration and layout of the structure. A ductile layout includes redundancy, meaning that if one part of the structure fails, others can take over the load, preventing collapse. This can be achieved by designing structures with multiple load paths and ensuring that critical elements are strategically placed to promote overall flexibility.

Examples & Analogies

Think of a team in a relay race where each runner has a specific job. If one runner stumbles, the others can adjust and still complete the race successfully. Similarly, in a structural system, even if one part experiences failure, the remaining components can work together to maintain the integrity of the whole structure.

Key Concepts

-

Material Ductility: The importance of using quality materials to avoid brittle failures and enhance energy absorption during seismic events.

-

Structural Ductility: The role of design and detailing in enabling structural members to deform effectively under loads.

-

System Ductility: The significance of redundancy and layout in improving the overall ductility of reinforced concrete structures.

Examples & Applications

High-quality steel rebars in an RC structure contribute to overall ductility by allowing the structure to deform without significant strength loss.

In a well-designed building, if one beam fails due to an earthquake, other beams can take on the load, demonstrating system ductility.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In every beam, in all we plan, Quality's key, to make a stand;

Stories

Once upon a time, a bridge was built with great care, reinforced with strong steel; when a storm came, its true ability to twist and bend was revealed, safe from collapse.

Memory Tools

Remember 'MSS': Material, Structural, System ductility for lasting stability.

Acronyms

To recall ductility's sources, think 'M.S.S.' for Material, Structural, System.

Flash Cards

Glossary

- Material Ductility

The ability of a material, specifically steel and concrete, to undergo deformation without significant strength loss.

- Structural Ductility

The ductility achieved by designed and detailed structural members that can deform under load.

- System Ductility

The overall ductility that results from the configuration and redundancy of structural elements.

- Confined Concrete

Concrete that is reinforced in such a way to enhance strength and ductility, particularly in critical areas.

Reference links

Supplementary resources to enhance your learning experience.