Strategies to Enhance Ductility in RC Structures

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Capacity Design Approach

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will discuss the capacity design approach, which ensures structures fail ductily. What does that mean? Can anyone explain?

Does it mean that we want beams to fail before columns?

Exactly! This principle is crucial because it helps to control where failure occurs, preventing catastrophic collapse. Remember, beams should yield first to absorb energy.

So, if the columns are stronger than the beams, does that mean the whole structure can become unstable?

Correct! That's known as the strong column-weak beam design. How can we remember this concept?

Maybe we can use the acronym SC-WB?

Great idea! SC-WB stands for Strong Column - Weak Beam. Remember, we want ductility to save lives during earthquakes.

Avoiding Over-Reinforced Sections

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's talk about over-reinforced sections. Why do we want to avoid them, class?

Because they can lead to brittle failure?

Correct! An over-reinforced section can’t deform significantly before failure occurs, which is dangerous in seismic conditions. How do we know if a section is well-reinforced?

By ensuring the tension reinforcement is balanced, right?

Exactly! We want a ratio of tension to compression reinforcement that allows for yielding. Can anyone recall from IS 13920 how many times the balancing steel we should have?

It should be at least 2.5 times the balancing steel!

Perfect! Remember, this helps guarantee the desired performance during seismic activity.

Use of High Strength Deformed Bars

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss high-strength deformed bars. How do these contribute to ductility?

They offer better tensile strength and help in energy absorption, right?

Exactly! Conforming to IS 1786 with Fe 415 or Fe 500 grades ensures maximum efficiency. How can their design influence our approach to detailing?

By ensuring proper laps, hooks, and bends are detailed according to the guidelines?

Absolutely! Good detailing is key in allowing these bars to perform effectively during seismic events. Remember, quality matters in materials.

Uniform Distribution of Stiffness and Mass

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss the distribution of stiffness and mass in a structure. Why do we want this to be uniform?

To ensure uniform displacement during seismic activities?

Exactly! Uniform distribution avoids stress concentrations and potential weak spots. How can this be achieved in design?

By using symmetrical layouts and evenly spacing materials?

Yes! Symmetry in both plan and elevation matters significantly. Any other factors we should consider?

Avoiding sudden changes in mass or stiffness, I think?

Correct! That keeps the structure stable and enhances overall ductility.

Proper Detailing of Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's discuss joint detailing. What's the importance of proper detailing here?

It prevents premature failure at critical points, like beam-column joints?

Exactly! Adequate anchorage and confinement are crucial in these joints to maintain ductility under loads. Can anyone summarize how we ensure this?

By following the guidelines in IS 13920 regarding anchorage length and confinement reinforcement?

Perfect! Remember, strong joints yield a more ductile structure overall, enhancing safety during seismic events.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Ductility is essential in earthquake-resistant design to prevent sudden failures. This section discusses strategic approaches like the capacity design method, avoiding over-reinforcement, uniform material distribution, and adherence to IS 13920 detailing requirements to enhance the ductility in RC structures.

Detailed

Ductility is a critical property in engineered structures, enabling them to endure significant deformations without catastrophic failure. This section describes various strategies to enhance ductility in reinforced concrete (RC) structures, which is particularly crucial during seismic events. Key strategies include adopting a capacity design approach to ensure beams yield before columns, avoiding over-reinforced sections in favor of tension-controlled designs, and ensuring uniform stiffness and mass distribution in the structural layout. The usage of high-strength deformed bars as per IS 1786, along with proper detailing of laps, hooks, and bends according to guidelines in IS 13920, is emphasized to prevent premature failures. Additionally, proper anchorage and confinement in beam-column joints are highlighted as vital components to bolster ductility in the overall structural system.

Youtube Videos

![Ductile Design and Seismic Detailing in RC Buildings [Ep 1.2]](https://img.youtube.com/vi/gTXVXQ-x8Yk/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Capacity Design Approach

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Capacity Design Approach: Ensure that the structure fails in a ductile manner — typically beams before columns.

Detailed Explanation

The Capacity Design Approach is a method used to ensure that when a structure experiences large forces, such as during an earthquake, it will deform but not collapse suddenly. This method emphasizes that beams should yield (or deform) before columns, allowing controlled damage to happen. Essentially, this means the structure is designed so that the weaker parts (beams) will give way first, providing energy absorption and warning signs, instead of allowing a more critical part (columns) to fail first.

Examples & Analogies

Think of a suspension bridge where the cables are designed to stretch and take on extra load before the bridge deck itself fails. When faced with high winds or earthquakes, the cables allow for some movement, which protects the more rigid parts of the bridge structure, similar to how ductility works in RC structures.

Avoid Over-reinforced Sections

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

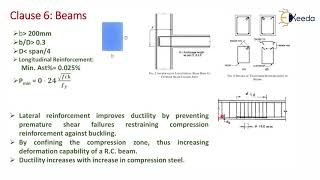

- Avoid Over-reinforced Sections: Tension-controlled sections are preferable.

Detailed Explanation

Over-reinforced sections occur when too much reinforcement steel is added to a concrete element. This configuration makes it difficult for the structure to bend or deform under loading; instead, it may fail suddenly, leading to brittle failure. Tension-controlled sections have a more balanced amount of reinforcement that allows them to yield and deform under stress, thereby absorbing energy during seismic events.

Examples & Analogies

Imagine a rubber band. If you stretch it just enough, it will return to its original shape. However, if you over-stretch it or put too much pressure on it, it will snap. Similarly, having just the right amount of steel reinforcement allows concrete to bend and flex without breaking.

Avoid Sudden Changes in Stiffness or Mass

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Avoid Sudden Changes in Stiffness or Mass: Uniform distribution ensures uniform displacement.

Detailed Explanation

Sudden changes in stiffness or mass within a structure can lead to uneven distribution of forces during seismic events. This can cause parts of the structure to respond differently, leading to potential failures. To maintain ductility, it's important that materials and structural elements are distributed uniformly, promoting consistent movement and force distribution throughout the entire structure.

Examples & Analogies

Think of how a group of dancers performs their routine. If one dancer is much heavier or stiffer than the others, it can disrupt the harmony and cause the formation to break apart. Similarly, uniformity in a building allows it to move together smoothly during shaking.

Use of High Strength Deformed Bars

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Use of High Strength Deformed Bars: Conform to IS 1786 with Fe 415/Fe 500 grade.

Detailed Explanation

High strength deformed bars (steel reinforcement) provide better bonding with concrete compared to smooth bars. They are designed to carry more load and enhance ductility, which is critical during dynamic loads such as earthquakes. Using bars that meet standards like IS 1786 ensures that they maintain structural integrity under significant stress.

Examples & Analogies

Consider the difference between a well-woven rug and a loose piece of fabric. The rug holds together better under pressure because its fibers are intertwined securely, just like how deformed bars grip concrete more effectively, resulting in stronger and more ductile structures.

Detailing of Laps, Hooks, Bends

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Detailing of Laps, Hooks, Bends: As per IS 13920 to avoid premature failure.

Detailed Explanation

Proper detailing of laps (where bars overlap), hooks, and bends in reinforcement is crucial to ensure that they can handle forces without failing prematurely. Standards like IS 13920 provide guidelines that help prevent weak points in the structure that could lead to unexpected failure during seismic events. Good detailing ensures that the connections between different components are strong and effective.

Examples & Analogies

Think of the way you tie knots in a rope. If you tie them properly, the rope remains strong and can bear a heavy load. If the knot is poorly tied or the rope is frayed, it might fail under tension. Similarly, well-detailed connections in structure reinforcements are key to achieving overall strength.

Joint Detailing

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Joint Detailing: Proper anchorage, bar cutoff, and confinement in beam-column joints.

Detailed Explanation

The joints between beams and columns are critical points in a structure. Proper anchorage (how bars are connected), bar cutoff (where bars stop), and confinement (using extra reinforcement) ensure that these joints can endure the forces applied during an earthquake. Good joint detailing can significantly enhance the overall strength and ductility of the entire structure.

Examples & Analogies

Imagine the corners of a picture frame. If the corners are reinforced and securely held together, the frame will remain intact even if bumped. In contrast, if the corners are weak, the entire frame might fall apart easily. Similarly, well-designed joints in a structure help maintain stability and ductility.

Key Concepts

-

Capacity Design: Ensuring beams yield before columns during seismic events.

-

Over-Reinforcement: Avoiding excessive reinforcement to prevent brittle failure.

-

High Strength Deformed Bars: Using quality materials to enhance strength and ductility.

-

Uniform Distribution: Maintaining consistent stiffness and mass distribution for stability.

-

Joint Detailing: Adding confinement and proper anchorage to critical connections.

Examples & Applications

In a high-rise building in a seismic zone, using the capacity design approach led to beams failing before the columns, providing a safe evacuation route.

An under-reinforced section in a RC structure designed with deformed bars proved to absorb energy effectively compared to a structure with hooped reinforcement points.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When beams do bend and joints do hold, a ductile structure shines like gold.

Stories

Imagine a magician who bends a metal rod without breaking it. The trick lies in understanding where to apply the force just as we ensure beams can flex without snapping under pressure.

Memory Tools

RC DUCT: Reinforcement, Capacity design, Uniform distribution, Concrete quality, Joint detailing, Tension-controlled sections.

Acronyms

B-C-J

Beams yield

Columns safe

Joints strong.

Flash Cards

Glossary

- Ductility

The ability of a structure or material to undergo significant deformation without losing strength.

- Capacity Design

A design philosophy that ensures structures fail in a controlled manner, typically with beams yielding before columns.

- OverReinforcement

A condition where a structural member has more reinforcement than required, potentially leading to brittle failure.

- Deformed Bars

High-strength steel bars with surface deformations that improve bond strength with concrete.

- Joint Detailing

The specification of reinforcement and connections at critical junctions of structural members.

- IS 13920

An Indian Standard code for seismic design that provides guidelines for ductile detailing of RC structures.

Reference links

Supplementary resources to enhance your learning experience.