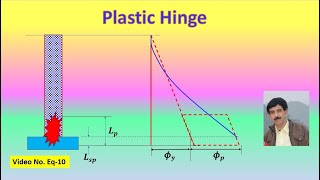

Plastic Hinges and Their Role in Ductility

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Plastic Hinges

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss plastic hinges and their crucial role in ductility. Can anyone tell me what a plastic hinge is?

Is it a part of the structure that can twist or bend without losing strength?

Exactly! Plastic hinges form at locations where the material yields and can rotate significantly without major increases in stress. This is crucial for energy dissipation during earthquakes.

Why do we want plastic hinges mainly in beams?

Great question! We design them to form in beams to ensure that columns remain elastic, which maintains strength in the overall structure. This setup allows for effective energy absorption and prevents sudden failures.

What about confinement? How does that play into hinge rotation?

Confinement is crucial! Adequate confinement around plastic hinges enables the member to sustain larger curvatures without fracturing—this is essential for achieving ductility.

Can you summarize what we covered about plastic hinges?

Sure! Plastic hinges allow beams to rotate under stress without significant moment increase, allowing controlled deformation and energy absorption during seismic events, while proper design ensures that the plastic hinges develop at pre-determined locations.

Design Considerations for Plastic Hinges

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we know what plastic hinges are, let's discuss some of the key design considerations. What do you think is important for their location?

They should be where the most stress is expected, like beam ends or column bases?

Exactly! Plastic hinges typically form at beam ends and column bases, where moments are highest during seismic events. Remember, this planning minimizes unexpected failures.

What about the overstrength factor?

Good point! The overstrength factor ensures that elements beyond the hinge can still resist higher moments. This prevents uncontrolled failures by allowing for some flexibility in the design.

And rotation capacity?

Rotation capacity is essential! We need sufficient confinement around the hinge areas, which allows these sections to deform adequately without fracturing, ensuring the structure can dissipate energy effectively.

Can we summarize the design features for plastic hinges?

Of course! Key design features include strategic placement at beam ends, ensuring overstrength in connected members, and providing adequate confinement to enable significant rotation capacity.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

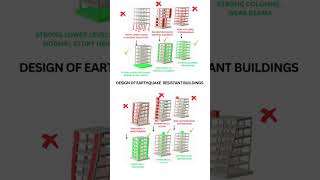

Plastic hinges are designed to form at specific locations, primarily beam ends and columns, to manage deformation during seismic loading. This design ensures energy is absorbed in predetermined areas to prevent sudden failures.

Detailed

In the context of reinforced concrete (RC) structures, plastic hinges are critical for enhancing ductility. They are points where sections yield under seismic loads and can rotate significantly without a notable increase in moment. The strategic placement of plastic hinges at beam ends and column bases is essential for allowing controlled inelastic deformations. Ensuring that plastic hinges are created primarily in beams—not columns—is necessary for maintaining overall structural integrity. Key design considerations include determining appropriate plastic hinge locations, ensuring overstrength factors to accommodate increased moments, and providing adequate confinement to promote the rotation capacity and ductility of the plastic hinge zones.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Plastic Hinges

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Plastic hinges are locations where the section yields and undergoes large rotations under seismic loads without significant increase in moment.

Detailed Explanation

Plastic hinges form at specific points in reinforced concrete structures during seismic events. These points are designed to yield, meaning they can bend significantly without breaking. This characteristic allows the structure to absorb and dissipate the energy released during an earthquake. Instead of the moment (the turning effect) drastically increasing, the plastic hinges allow for rotation, enabling the structure to undergo deformations in a controlled manner. This is crucial for preventing sudden collapses during seismic events.

Examples & Analogies

Imagine a well-designed swing that bends at the joints instead of breaking when too much weight is applied. As the swing bends, it can still hold onto its overall form, absorbing energy from the force applied. Similarly, plastic hinges in a building act like these flexible joints, allowing movement but maintaining the structure's integrity.

Design Considerations for Plastic Hinges

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Designing for plastic hinges ensures that energy is dissipated in pre-defined regions rather than through sudden failure.

Detailed Explanation

In the design of reinforced concrete structures, specifying where plastic hinges should form is essential. This expectation means engineers can predict how and where a structure will yield under stress. Pre-defined regions, usually at the ends of beams and bases of columns, are made to withstand high moments while concealing the risk of sudden structural failure in other areas. By focusing on these specified locations for yielding, the overall safety and ductility of the structure are improved.

Examples & Analogies

Think of a safety release valve in a pressure cooker. If the pressure builds up too much, this valve opens to alleviate the pressure in a controlled manner rather than the entire device exploding. Plastic hinges function in a similar way by having designated locations that can absorb and manage stress, preventing failures elsewhere in the structure.

Plastic Hinge Locations

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Typically at beam ends and base of columns.

Detailed Explanation

Engineers strategically place plastic hinges at beam ends and column bases where the structure typically experiences the most stress during seismic events. By concentrating the potential for yielding in these locations, all the energy from the seismic forces can be dissipated there, allowing the rest of the structure to remain intact and stable. This design consideration ensures that other critical areas, such as the columns, can stay elastic and avoid failure.

Examples & Analogies

Imagine a bridge that sways during strong winds — the joints at the ends can flex and absorb that motion without compromising the entire bridge's stability. This is akin to placing plastic hinges specifically where the bends can safely occur, protecting the overall structure from significant damage.

Overstrength Factor and Rotation Capacity

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

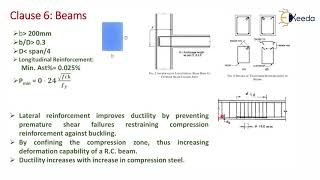

Overstrength Factor: Ensure sections beyond plastic hinge can resist increased moment.

Rotation Capacity: Adequate confinement to enable curvature ductility.

Detailed Explanation

To manage the forces effectively during an earthquake, structural elements beyond the plastic hinge must be designed to handle moments greater than those at the hinges. This is known as the overstrength factor — it ensures that even when the sections near the hinges yield, the adjacent areas remain robust enough to absorb the additional forces. Furthermore, rotation capacity refers to ensuring that the materials used at the plastic hinges can bend without breaking, facilitating ductility and preventing sudden failures.

Examples & Analogies

Consider a rubber band that can stretch. If it's too thin and weak, it might snap under a little tension, but if it's thick and sturdy, it can stretch considerably without breaking. In a similar fashion, the sections beyond the plastic hinge need to be designed to stretch (or rotate) adequately under stress, maintaining the strength necessary to hold the structure together during seismic events.

Avoidance in Columns

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Columns are designed to remain elastic; plastic hinges should form in beams.

Detailed Explanation

It's vital for the structural integrity that columns remain elastic during seismic events. Columns are the primary load-bearing components and should not yield or deform like beams can. Instead, plastic hinges are intended to develop in beams. This design philosophy helps prevent a soft-story collapse, as the yielding mechanism must always favor beam failure over column failure, thus maintaining the stability of the vertical structure.

Examples & Analogies

Think of a building as a team of players where each player has a specific role. If the strongest player (the column) collapses, the whole team falls apart. By making sure that the weaker players (the beams) can bend and yield instead, the team can adapt to pressure without losing its overall form, ensuring the structure stands firm even under duress.

Key Concepts

-

Plastic Hinge: A pivotal point formed in beams at which yielding occurs, enabling deformation without significant moment increase.

-

Ductility: The capacity of a structure to undergo substantial deformation before failure, crucial in seismic design.

-

Design Considerations: Key factors like hinge location, overstrength, and confinement that ensure effective plastic hinge function.

Examples & Applications

Designing plastic hinges at the ends of beams in a residential building to allow for controlled deformation during an earthquake.

Utilizing confining reinforcement in plastic hinge regions to prevent sudden failure and ensure energy dissipation.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In beams where they hinge, moments remain, keeping the structure stable through shaking and strain.

Stories

Imagine a dancer (the beam) who bends gracefully at the ends (plastic hinges), while the strong pillar (column) stands firm, ensuring the dance doesn’t end in a fall.

Memory Tools

Remember 'C.R.O.W.' for plastic hinge design: Confinement, Rotation capacity, Overstrength, and Where to place it!

Acronyms

D.H.O.C. - Ductility, Hinge location, Overstrength, and Confinement are key in design.

Flash Cards

Glossary

- Plastic Hinge

A location in a structural member where yielding occurs, allowing significant rotations without a corresponding increase in moment.

- Ductility

The ability of a material or structure to undergo large deformations before failure.

- Overstrength Factor

A design parameter ensuring that a structure can withstand greater moments than those considered in standard calculations, enhancing safety.

- Confinement

Reinforcement techniques applied to concrete to improve its strength and ductility, particularly in critical regions like plastic hinges.

Reference links

Supplementary resources to enhance your learning experience.