Flow Classifications and Control Volumes

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Flow Classifications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome to our session on flow classifications! Today, we're diving into the differences between steady and unsteady flows. Can anyone tell me what they think the main difference is?

I think steady flow means the velocity at a point doesn't change over time?

Exactly! In steady flow, parameters like velocity and pressure remain constant at each point with time. On the other hand, in unsteady flow, these parameters can change. Let's remember that with the acronym 'SU': Steady = Static; Unsteady = Unpredictable.

So, when we're designing buildings, why do we care about whether the flow is steady or unsteady?

Great question! Understanding the type of flow is crucial for predicting forces and pressure distributions on structures. This leads us into our next topic!

Control Volumes Concept

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s discuss control volumes. What is a control volume?

Is it a defined region in space where we analyze fluid?

Correct! The control volume allows us to apply conservation laws like mass, momentum, and energy. We can visualize these as 'zones of analysis.' Anyone remember the different types of control volumes?

There are fixed and moving control volumes, right?

Exactly! Fixed control volumes don't change position, while moving ones do. This distinction is important for our calculations!

Reynolds Transport Theorem

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we need to understand the Reynolds transport theorem. Why do we use it?

It helps us connect the change in a property within a control volume to the flow across its boundaries, right?

Yes! It allows us to relate forces inside and outside the control volume, making our equations easier to handle. Let’s create a memory aid: 'R for Relate, T for Transport.'

How do we apply this to our equations?

We simplify by recognizing when flow is steady, allowing us to ignore time derivative terms, which leads us to define forces acting on the control volume more easily.

Momentum Flux Correction Factors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about momentum flux correction factors. Why are they important?

They account for non-uniform velocity distributions through a control surface, correct?

Yes! If the velocity is not uniform, we must adjust the calculations to accurately capture the momentum. Remember: 'R is for Rate of change!'

What impact does this have in real-world applications?

It allows for more accurate force and pressure predictions in scenarios like water jet impacts on structures—crucial for design safety!

Applications of Control Volumes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s review some applications of control volumes in engineering. What are some examples?

We can use them to analyze the forces on a bridge due to water flow!

Or when designing pipes and channels for fluid transport!

Exactly! Whether it's predicting pressure distributions or calculating forces on structures, the concepts of flow classifications and control volumes are vital in engineering. Let’s remember: 'F is for Fluid forces!' as our final mnemonic!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section emphasizes the significance of fluid flow classifications, such as steady-state flows and various control volume types. It addresses how these principles apply to real-world applications, particularly through momentum conservation and correction factors in different engineering contexts.

Detailed

In this section, we explore flow classifications and control volumes, which are essential in the study of fluid mechanics. We discuss the types of flow, including steady and unsteady flows, and cover the importance of control volumes in analyzing forces acting on a fluid. The Reynolds transport theorem is introduced, emphasizing its role in simplifying momentum conservation equations. We learn to distinguish between fixed and moving control volumes, identify body forces and surface forces, and apply concepts like momentum flux correction factors in practical engineering scenarios. Through visual aids and problem-solving examples, the significance of these concepts in real-life applications such as bridge design and flow around structures is highlighted.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Flow Classifications

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Flow can be classified in various ways based on different criteria such as direction, steady or unsteady states, compressibility, and type of fluid. Understanding these classifications helps in selecting the appropriate equations to describe fluid behavior in different scenarios.

Detailed Explanation

Fluid flow is categorized based on several characteristics. The most common classifications include:

1. Steady vs. Unsteady Flow: In steady flow, the fluid properties at any given point do not change over time, whereas, in unsteady flow, they do change.

2. Uniform vs. Non-uniform Flow: In uniform flow, the velocity of the fluid remains constant along a streamline, while in non-uniform flow, it varies.

3. Laminar vs. Turbulent Flow: Laminar flow is smooth and orderly, characterized by layers of fluid that do not mix, while turbulent flow is chaotic and involves mixing of layers.

4. Compressible vs. Incompressible Flow: Incompressible flow assumes constant fluid density, primarily applicable to liquids, while compressible flow considers density variations, relevant for gases, especially at high speeds.

Examples & Analogies

Think of water flowing steadily through a garden hose (steady flow) versus water splattering everywhere when the hose is suddenly kinked (unsteady flow). In the case of the steady flow, you can predict what happens when you turn on the faucet at a constant rate. However, if you're considering a situation where a water balloon is popped, you can observe the chaotic nature of fluids all around, illustrating turbulent flow.

Understanding Control Volumes

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Control volumes are essential in fluid mechanics as they allow for the analysis of fluid flow and behavior. A control volume is a defined region in space through which fluids may flow, and it can be fixed in position or moving.

Detailed Explanation

A control volume is an imaginary boundary that helps analyze the behavior of fluids entering and exiting a system. This boundary can be static (fixed control volume) or dynamic (moving control volume). The analysis involves applying the principles of conservation of mass, momentum, and energy across the control volume. In the context of fluid mechanics, the control volume helps simplify calculations by focusing on the mass and momentum input/output rather than the complex flow patterns inside the volume.

Examples & Analogies

Imagine a swimming pool: if you consider the pool as a control volume, you can measure how much water flows in from a hose and how much flows out when someone splashes or when the pool is drained. By focusing on the inlets and outlets, you simplify the process of understanding how much water is in the pool at any given time.

Forces Acting on Control Volumes

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Two types of forces act on a control volume: body forces (like gravity) and surface forces (like pressure and viscous forces). Understanding these forces is vital for applying the principles of momentum.

Detailed Explanation

In fluid mechanics, the forces acting on a control volume are categorized into two types:

1. Body Forces: These are the forces that act throughout the volume of the fluid, such as gravity or electromagnetic forces. For instance, the weight of the fluid due to gravity acts on the entire control volume.

2. Surface Forces: These forces act on the boundary surfaces of the control volume, including pressures and shear stresses. They arise from the interaction between the fluid and the surfaces it contacts.

To analyze fluid flow using momentum equations, it is important to account for both types of forces when assessing the net force acting on the control volume.

Examples & Analogies

Consider a boat floating on a lake. The force of gravity pulling the boat down is a body force. However, the water pushing up against the bottom of the boat (buoyancy) and any wind or waves affecting the boat's surface are examples of surface forces. Recognizing and calculating these forces allows engineers to determine how the boat will respond to various conditions in the water.

Momentum Flux Correction Factors

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

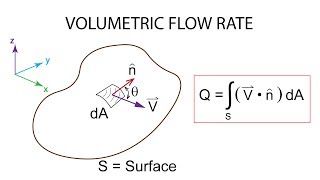

Chapter Content

When dealing with non-uniform velocity distributions, momentum flux correction factors are crucial in accurately calculating the momentum flux passing through a control surface. These factors adjust calculations based on the actual flow characteristics.

Detailed Explanation

Momentum flux correction factors (β) account for the deviations in velocity distribution across a cross-section of flow. When the velocity is uniform, β equals 1. However, in practical applications, especially in turbulent or varied flows, the velocity distribution is rarely uniform, necessitating the use of correction factors to adjust momentum calculations. The correction factor compensates for the average velocity when compared to the variable velocities across the control surface, making it crucial for precise calculations of forces and momentum in fluid systems.

Examples & Analogies

Imagine pouring syrup over pancakes. If you pour it evenly, the syrup spreads uniformly (imagine a β of 1). However, if you pour it at an angle, the syrup may flow faster in some areas and slower in others, leading to patches of thicker syrup in some spots and thinner in others. This variation is akin to how fluid flows through a pipe, where some regions have higher velocities than others, demonstrating why correction factors are necessary for accurate calculations.

Key Concepts

-

Flow Classifications: Understanding the types of flows, steady and unsteady, and their impact on fluid dynamics.

-

Control Volumes: The concept of analyzing a defined region to solve fluid mechanics problems.

-

Reynolds Transport Theorem: A key theorem for applying fluid mechanics principles to control volumes.

-

Momentum Flux: The importance of accounting for momentum in fluid dynamics and engineering designs.

-

Momentum Flux Correction Factors: Adjustments needed for non-uniform velocity distributions in real-world applications.

Examples & Applications

Analyzing the forces on bridge piers due to unsteady water flow.

Using control volumes to calculate the pressure distribution in a pipe system.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When flow is steady, it's calm and neat, unsteady brings chaos with changes to meet.

Stories

Imagine a river flowing steadily under a bridge. If a storm causes the river's flow to change rapidly, it acts like the unsteady flow affecting the bridge's structure.

Memory Tools

Remember 'R for Relate, T for Transport' for figuring out the Reynolds Transport Theorem.

Acronyms

Use 'BFS' to remember Body Forces, Surface Forces, and the significance of both in analyzing controls.

Flash Cards

Glossary

- Flow Classification

The categorization of fluid flows based on characteristics like steadiness.

- Control Volume

A defined region in space used for analyzing fluid motion and energy transfers.

- Reynolds Transport Theorem

A theorem that relates the change in a fluid property inside a control volume to the flow of that property across the control surface.

- Momentum Flux

The measure of the quantity of motion conveyed by a flow per unit cross-sectional area.

- Momentum Flux Correction Factor

A factor used to account for non-uniform velocity profiles when calculating momentum flux.

- Body Forces

Forces that act throughout the volume of a body, e.g., gravitational force.

- Surface Forces

Forces that act on the surface of a control volume, such as pressure and friction.

Reference links

Supplementary resources to enhance your learning experience.