Conclusion

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

The Importance of IC Packaging Reliability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will revisit why reliability in IC packaging is so vital. What can happen if an IC fails in consumer electronics or automotive systems?

It can lead to system failures, right? Like a phone not working or a car malfunctioning.

Exactly! An unreliable IC can lead to costly repairs and poor performance. That’s why we focus so much on mechanical stress, thermal cycling, and other factors.

Can you explain what mechanical stress is again?

Certainly! Mechanical stress refers to forces that ICs experience due to handling, thermal expansion, or vibrations. It’s essential we design packages to withstand these stresses.

What are some examples of how these stresses affect the IC?

Well, issues like cracking or delamination can occur due to thermal cycling. Remember the acronym 'MTM' for Mechanics, Thermal management, and Materials!

Got it! Can you recap why these factors matter?

Sure! Reliability affects performance and longevity in semiconductor devices, impacting everything from design to testing.

Testing Techniques for Reliability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's explore the testing techniques that help ensure IC packages are reliable. Who can name one of these techniques?

Accelerated life testing? I’ve heard of it.

Good! ALT simulates long-term environmental stresses in a short period. Why do we do this?

To find weaknesses before they reach consumers?

Absolutely! And how about moisture sensitivity testing? What do you think it assesses?

It checks how moisture affects the IC packages?

Exactly! Remember the critical phrase: 'Moisture in, failure out.' Each technique helps identify potential failure modes.

That’s cool! Can you summarize these testing methods?

Sure! Test methods like ALT and moisture sensitivity testing play a key role in validating the performance of IC packages before they are deployed.

Future Directions in IC Packaging

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

As we wrap up today's discussion, let’s reflect on the future of IC packaging. What trends might we see in improving reliability?

I think new materials will be developed that are more heat resistant?

Great insight! Innovations like high-performance ceramics can significantly enhance reliability.

What role does failure analysis play in this?

Excellent question! Failure analysis helps us understand past issues, ensuring we don’t repeat mistakes. It’s a learning tool.

So, continuous learning helps improve designs?

Exactly! Continuous advancement in materials and testing methodologies is vital for meeting rising industry reliability standards.

Can you finish by summarizing our session?

Certainly! Future directions in IC packaging involve embracing innovations in materials, rigorous failure analysis, and constantly updating our testing protocols.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In the conclusion, the reliability of IC packaging is highlighted as a fundamental component for ensuring the effective and long-lasting functionality of semiconductor devices. Addressing mechanical stress, thermal cycling, and moisture exposure, along with implementing robust testing techniques, is essential for meeting modern industry standards.

Detailed

Conclusion

The reliability of integrated circuit (IC) packaging is a critical factor in ensuring that semiconductor devices function efficiently throughout their intended lifespan. Given the variety of applications, ranging from consumer electronics to automotive systems, the packaging must withstand diverse environmental challenges. Key factors affecting reliability include mechanical stress, thermal cycling, and moisture exposure. To mitigate failures, manufacturers must employ rigorous testing and validation techniques that simulate real-world conditions. This comprehensive approach not only ensures the safety and performance of IC packages but also meets the continuing advancements in material science and testing methodologies, thereby addressing the growing reliability standards of the electronics industry.

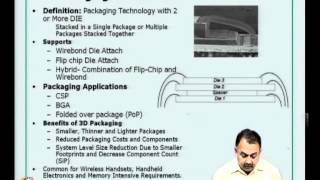

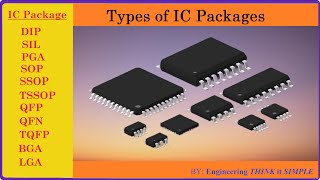

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Reliability in IC Packaging

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The reliability of IC packaging is a critical factor in ensuring the performance and longevity of semiconductor devices.

Detailed Explanation

This chunk emphasizes that reliability is essential for Integrated Circuit (IC) packaging. It means that the packaging must be dependable, allowing semiconductor devices to work efficiently for a long time. The packaging protects the IC from physical and environmental stresses, which helps the devices perform well throughout their lifecycle.

Examples & Analogies

Think of IC packaging like the protective casing of a smartphone. Just as the phone case keeps the internal components safe from drops and spills, reliable packaging ensures that the semiconductor works well under various conditions.

Addressing Key Reliability Factors

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

By addressing factors such as mechanical stress, thermal cycling, and moisture exposure, and implementing robust testing and validation techniques, manufacturers can ensure that their IC packages meet the demands of modern applications.

Detailed Explanation

This section identifies specific factors that can threaten the reliability of IC packaging, like mechanical stress from physical impacts, thermal cycling due to temperature changes, and moisture which can lead to deterioration. By tackling these challenges through robust testing and validation methods, such as accelerated life testing and moisture sensitivity testing, manufacturers can enhance the resilience of their IC packages, making them more suited to current technological needs.

Examples & Analogies

Consider how a car manufacturer tests their vehicles in extreme conditions (like high heat, heavy rain, and rough terrains). This practice is similar to how IC manufacturers test their products under various scenarios, making sure that IC packages can endure their use in electronics, similar to how a car is ensured to handle varied driving conditions.

Advancements in Material Science and Testing

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

With continuous advancements in material science and testing methodologies, IC packaging will continue to evolve to meet the increasing reliability standards of the electronics industry.

Detailed Explanation

This chunk refers to ongoing improvements in the materials used for IC packaging and the methods employed to test them. As researchers develop better materials that can withstand harsh conditions and more effective testing techniques that can simulate real-world scenarios, the reliability standards for IC packaging will rise. This evolution helps keep pace with the fast-developing electronics industry’s demands for higher performance and longer-lasting products.

Examples & Analogies

Imagine how smartphone screens have evolved from fragile glass to more durable, scratch-resistant materials. Similarly, IC packaging is undergoing advancements to provide better protection and longevity, thus evolving to meet the high expectations of tech consumers.

Key Concepts

-

Reliability: Critical for performance and longevity of IC packages.

-

Mechanical Stress: Forces causing potential physical damage to ICs.

-

Testing Techniques: Validating performance through rigorous methodologies.

Examples & Applications

A smartphone that fails to function due to poor IC reliability can cause significant frustrations for users and financial losses for manufacturers.

In automotive applications, an unreliable IC package could lead to critical failures such as engine shutdowns or malfunctioning safety systems.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Reliability, integrity, under stress, we must test; ensure the IC's the best!

Stories

Imagine an engineer designing an IC. He checks every material, tests pieces for stress, to ensure the device is built to impress.

Memory Tools

Remember 'M.M.T.' for Mechanical stress, Moisture impact, Thermal management in reliability.

Acronyms

Use 'R.M.T.' for 'Reliability Must Test' to remember the importance of testing for ICs.

Flash Cards

Glossary

- Integrated Circuit (IC)

A set of electronic circuits on one small flat piece or

- Reliability

The probability that an IC will perform its intended function for a specified period under stated conditions.

- Mechanical Stress

Forces applied to ICs that can cause physical damage or stress.

- Thermal Cycling

Repeated temperature changes that materials undergo which can create stress and damage.

- Moisture Sensitivity

The degree to which an IC is affected by environmental moisture, leading to potential failures.

Reference links

Supplementary resources to enhance your learning experience.