Introduction to Reliability in IC Packaging

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Reliability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ll explore the significance of reliability in integrated circuit packaging. Can anyone tell me why reliability is so important?

Because it prevents failures in electronic devices, right?

Exactly! An unreliable IC can lead to costly repairs and affect performance in critical applications like automotive systems. Let’s remember the acronym P.R.O.V.E: Performance required, Reliability over time, Operational conditions, Value at risk, and End-user satisfaction.

What kinds of applications are particularly affected by this reliability issue?

Great question! Applications in consumer electronics and automotive systems are especially sensitive due to their reliance on consistent performance. So, what do you think happens if an IC fails in an automotive application?

It could lead to accidents or failures in critical systems, right?

Exactly. Understanding these factors and their implications is key for designers and manufacturers to ensure reliability in IC packaging.

Factors Influencing Reliability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand the importance, let’s look at the main factors influencing IC reliability. Can anyone list some?

I think material selection is crucial.

Absolutely! Material selection can impact thermal conductivity and mechanical stress. Along with that, there are thermal management techniques. Does anyone know what happens if we don’t manage heat effectively?

It can lead to overheating or even failure of the IC.

Correct! Overheating can cause solder melting or cracks in the die. Remember the mnemonic H.E.A.T.: Heat management, Expansion control, Avoidance of failures, Thermal reliability. Let’s discuss mechanical stress as well.

How does mechanical stress affect ICs?

Mechanical stress can occur from board flexing or thermal cycling. Continuous expansion and contraction may lead to cracking or interface delamination. Keeping these factors in mind during design ensures better reliability.

Testing and Validation Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To ensure reliability, there are several testing and validation techniques available. Who can name one?

Accelerated Life Testing?

That’s correct! Accelerated Life Testing simulates environmental factors over a short duration allowing manufacturers to observe potential failure modes before deployment. Can anyone think of what kinds of environmental factors are simulated?

Temperature changes and humidity?

Exactly. Thermal cycling and moisture sensitivity tests are critical components. Let’s also discuss mechanical stress testing. What is its purpose?

To see how the ICs withstand shocks and vibrations?

Right! Downtime or failures due to mechanical stress can be costly, particularly in sectors like aerospace.

Addressing Reliability Challenges

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s conclude with strategies for improving reliability in IC packaging. What do you think manufacturers should focus on?

They should use better materials.

Absolutely! Material innovation can lead to better moisture resistance and mechanical strength. Another strategy is Design for Reliability. Why do you think that is important?

It helps create products that are more robust from the beginning, rather than fixing failures later.

Exactly, remembering to incorporate testing and validation methods into the design phase can significantly reduce future issues. Let’s wrap up by highlighting that reliability in IC packaging is essential for ensuring a product's lifecycle and operational success.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The introduction focuses on the importance of reliability in IC packaging, discussing how factors such as material selection, mechanical stress, and thermal management influence the longevity and performance of ICs. It sets the stage for a deeper exploration of the various testing and validation methodologies employed to ensure packaged IC reliability.

Detailed

Introduction to Reliability in IC Packaging

Reliability is a critical factor in the design and manufacturing of integrated circuit (IC) packages, emphasizing that unreliable ICs can result in significant system failures, expensive repairs, and diminished performance across diverse applications, ranging from consumer electronics to automotive systems. As the interface between the microelectronics and their operational environments, IC packaging is crucial for ensuring consistent functionality throughout the lifespan of ICs, particularly under varying environmental conditions.

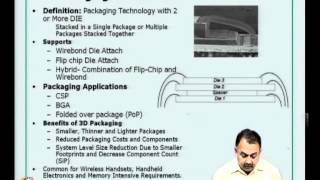

This section delves into key factors that impact the reliability of IC packaging, including:

- Material Selection: The choice of materials affects thermal management and protection against environmental elements.

- Mechanical Stress: Forces from handling, thermal expansion, and operational vibrations can lead to failures.

- Thermal Management: Ensures effective dissipation of heat, mitigating risks of overheating.

Moreover, it highlights testing and validation techniques that are vital for verifying the reliability of packaged ICs before they are deployed, ensuring they meet performance standards and can withstand real-world conditions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Reliability

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Reliability is a crucial consideration in the design and manufacturing of IC packages. An unreliable IC can lead to system failures, costly repairs, and compromised performance in a wide range of applications, from consumer electronics to automotive systems.

Detailed Explanation

Reliability in integrated circuit (IC) packaging refers to how consistently an IC operates correctly over time under different conditions. If an IC fails, it can disrupt systems that depend on it, leading to expensive downtime and repairs. For example, in a smartphone, if the IC package is unreliable and fails, the entire phone may stop functioning, which can be a huge inconvenience for users.

Examples & Analogies

Think of reliability like a sturdy bridge. If a bridge is built poorly, it can collapse, causing major traffic jams or even accidents. Similarly, if an IC package isn't designed for reliability, it might fail unexpectedly, leading to crashes in electronic devices.

Role of IC Packaging

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

IC packaging plays a vital role in ensuring that the packaged ICs function properly over their expected lifetime under various environmental conditions.

Detailed Explanation

IC packaging protects the sensitive electronic components from physical damage, moisture, and environmental factors. It also aids in heat dissipation, which is essential for the longevity of the IC. The packaging must withstand various conditions, such as temperature fluctuations and humidity, to ensure that the IC continues performing as expected throughout its intended lifespan.

Examples & Analogies

Imagine packaging a delicate gift. The packaging should protect the contents from being crushed or damaged. Similarly, IC packaging must safeguard the IC from environmental stresses that could lead to failure.

Exploring Factors Affecting Reliability

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

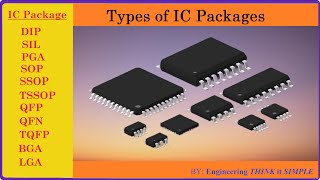

This chapter explores the key factors affecting the reliability of IC packaging, including material selection, mechanical stress, and thermal management, and outlines the common testing and validation techniques used to ensure the reliability of packaged ICs.

Detailed Explanation

Several interconnected factors impact the reliability of IC packages. Material selection includes choosing the right substances that can handle heat and moisture. Mechanical stress refers to the forces that the IC experiences during use, like bending or vibrations. Thermal management is how well the package dissipates heat to prevent overheating. Understanding these aspects allows manufacturers to create more reliable IC packages.

Examples & Analogies

Consider a car that uses high-quality materials for its engine, is designed to minimize stress while driving (like proper suspension), and has a cooling system to prevent overheating. Just like cars, IC packages need to account for materials, stress, and heat for optimal performance.

Key Concepts

-

Reliability: Ensuring consistent operation of ICs.

-

Thermal Cycling: A factor causing stress due to temperature variations.

-

Moisture Sensitivity: Evaluating risks related to humidity exposure.

-

Mechanical Stress: Damaging forces on IC packages.

-

Material Selection: Choosing the right materials for enhanced reliability.

Examples & Applications

Example 1: An automotive application experiencing a failure due to poor thermal management leading to overheating.

Example 2: Testing an IC through accelerated life testing reveals potential delamination issues that need addressing before mass production.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Reliability, oh please, keep devices at ease, make them last long, avoid failure's tease.

Stories

Imagine a car engine that overheats because the IC packaging isn’t reliable. It leads to trouble on the road. The smarter the design, the safer the journey!

Memory Tools

To remember the factors affecting reliability, think of M.T.M: Mechanical stress, Thermal management, and Material selection.

Acronyms

P.R.O.V.E

Performance required

Reliability over time

Operational conditions

Value at risk

End-user satisfaction.

Flash Cards

Glossary

- Reliability

The ability of an integrated circuit package to perform its intended function consistently over time under specific conditions.

- Thermal Cycling

The process of repeatedly heating and cooling a material, which can lead to expansion and contraction, affecting the integrity of IC packages.

- Moisture Sensitivity Testing

A method to evaluate how exposure to moisture affects the integrity and performance of IC packages.

- Mechanical Stress

Forces exerted on an IC package that can lead to physical damage, such as cracking or solder joint failure.

- Material Selection

The process of choosing appropriate materials for IC packaging that can withstand environmental conditions and mechanical stresses.

Reference links

Supplementary resources to enhance your learning experience.