Material Selection

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Thermal Conductivity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to discuss the significance of thermal conductivity in materials used for IC packaging. Why do you think this property is crucial?

I think it's important because if the materials can't conduct heat well, the IC might overheat?

Exactly! Poor thermal conductivity can trap heat, causing thermal stress. High-performance packages often use ceramics for their excellent thermal conductivity. Can anyone name an application where overheating might be a critical issue?

Maybe in mobile phones? They get really hot when using certain apps.

Great example! Now remember, we can use the acronym 'THC' to summarize the importance—Thermal, Heat, Conductivity. This will help you recall why it's vital in IC design.

Mechanical Strength

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss mechanical strength. Why do you think the mechanical properties of packaging materials are essential?

If they are weak, the IC could easily break during handling or in a device?

Exactly right! The materials should withstand forces like vibrations and shocks. Can anyone think of a scenario where mechanical failure could occur?

In cars, if the electronics can't handle bumps or vibrations, they might fail.

Perfect insight! Remember the mnemonic 'MSS' – Mechanical Strength is Sacred, to remind you how essential this property is.

Moisture Resistance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s explore moisture resistance. Why is it critical for packaging materials?

Maybe because moisture can cause corrosion and damage the circuits?

Yes! Moisture absorption can lead to issues like delamination and corrosion of metal contacts. What environments would this be especially concerning?

In humid climates, like near oceans!

Exactly! Let's use the acronym 'MRA'—Moisture Resistance is A must—to keep this concept in mind.

Material Selection Summary

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we've covered thermal conductivity, mechanical strength, and moisture resistance, how would you summarize their roles in IC reliability?

Quality materials can prevent failures from heat, physical stress, and environment?

That's a great summary! Think of these factors as three pillars supporting IC reliability. Remembering these will help in your future studies and understanding.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Material selection for IC packaging significantly affects the reliability of integrated circuits. Factors such as thermal conductivity, mechanical strength, and moisture resistance must be carefully considered during the design and manufacturing process to prevent failures and ensure longevity.

Detailed

Material Selection

The materials chosen for IC packaging, including encapsulation resins, substrates, and interconnect materials, play a critical role in the reliability of integrated circuits (ICs). This section explores three primary factors in material selection:

- Thermal Conductivity: Poor thermal conductivity can lead to heat retention, resulting in overheating and thermal stress within the IC. High-performance packaging often utilizes ceramic materials due to their superior thermal conductivity.

- Mechanical Strength: The mechanical properties of the materials must be robust enough to withstand external forces such as vibrations, shocks, and bending, preventing damage to the IC.

- Moisture Resistance: Packaging materials need to resist moisture absorption, particularly in high-humidity settings, to avoid issues like corrosion and delamination.

Selecting appropriate materials is fundamental to achieving reliability in ICs, and failure to do so can lead to significant performance and longevity issues.

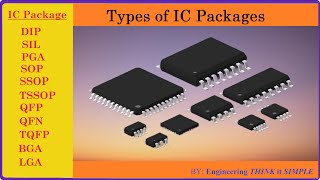

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Material Selection

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The materials used in IC packaging, such as encapsulation resins, substrates, and interconnect materials, play a significant role in determining the reliability of the IC. Key factors to consider include:

Detailed Explanation

In this chunk, we learn that the choice of materials for IC packaging is crucial for ensuring reliability. The materials, which include components like resins and substrates, influence how well the IC can perform under various conditions. This means that the decisions made during the material selection phase can have long-lasting effects on the function and durability of the IC.

Examples & Analogies

Think of material selection in IC packaging like choosing the right ingredients for a recipe. Just like using high-quality ingredients leads to a delicious dish, selecting the best materials results in reliable and effective ICs.

Thermal Conductivity

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Thermal Conductivity: Materials with poor thermal conductivity can trap heat within the IC, leading to overheating and thermal stress. High-performance packages often use ceramic materials for their excellent thermal conductivity.

Detailed Explanation

In this section, we explore thermal conductivity, which refers to how well a material can transfer heat. Materials that do not conduct heat well can cause overheating within an IC, resulting in failure. Therefore, materials with high thermal conductivity, like ceramics, are preferred in high-performance IC packaging because they help dissipate heat effectively, preventing thermal stress.

Examples & Analogies

Imagine a poorly insulated house during summer. The heat gets trapped inside, making it uncomfortable. Similarly, if an IC packaging material cannot effectively disperse heat, it can become 'uncomfortable' (overheated), leading to potential failure.

Mechanical Strength

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Mechanical Strength: The mechanical properties of packaging materials must be considered to ensure that the IC can withstand external forces, such as vibrations, shocks, or bending, without suffering damage.

Detailed Explanation

Mechanical strength describes how well a material can withstand external forces without breaking. In IC packaging, this is important because during operation, the IC might face vibrations or shocks. If the packaging materials are not strong enough, it could result in damage to the IC and lead to failure. Hence, selecting materials with appropriate mechanical properties is essential for durability.

Examples & Analogies

Think of mechanical strength like the material of a phone case. A strong phone case protects the device from drops and impacts, just as strong packaging protects an IC from mechanical stresses in its operating environment.

Moisture Resistance

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Moisture Resistance: Packaging materials must be resistant to moisture absorption, especially in high-humidity environments, to prevent corrosion and delamination.

Detailed Explanation

Moisture resistance refers to the ability of a material to resist absorbing water from the environment. For ICs, especially those used in humid conditions, moisture can cause serious problems like corrosion or delamination, where layers of the packaging separate. Choosing materials that do not absorb moisture is therefore critical to maintain the integrity and reliability of the IC.

Examples & Analogies

Consider a waterproof jacket. It protects you from getting wet in the rain. Similarly, moisture-resistant materials protect the ICs from environmental moisture, ensuring they remain functional and reliable.

Key Concepts

-

Thermal Conductivity: Essential for heat dissipation in ICs to prevent overheating.

-

Mechanical Strength: Critical for protecting ICs from physical stress during use.

-

Moisture Resistance: Prevents failure modes like delamination and corrosion.

Examples & Applications

Use of ceramic materials in IC packaging to enhance thermal conductivity.

Selection of epoxy resins that resist moisture absorption for electronic applications.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Thermal, mechanical, and moisture too, for reliable ICs, select the right crew.

Stories

Imagine a factory where ICs are made. If they choose weak materials, the ICs get hurt; they crack and can't run, and that's bad for the dirt, but if strong, they thrive, under heat waves and rain, for they withstand the pressure of any strain.

Memory Tools

Remember TMM - Thermal, Mechanical, Moisture - the three keys to reliable ICs.

Acronyms

MST - Materials for Strength and Thermal management.

Flash Cards

Glossary

- Thermal Conductivity

The ability of a material to conduct heat, critical for preventing overheating in ICs.

- Mechanical Strength

The property that determines how much force a material can withstand without failure.

- Moisture Resistance

The ability of a material to resist the absorption of moisture, preventing corrosion and degradation.

Reference links

Supplementary resources to enhance your learning experience.