Reliability in IC Packaging

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Reliability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome, class! Today, we'll dive into the critical topic of reliability in IC packaging. Can anyone tell me why reliability is so crucial for integrated circuits?

It's important because if an IC fails, it can cause major issues in devices, right?

Exactly, Student_1! An unreliable IC can lead to system failures and costly repairs. Reliability ensures performance over an IC's expected lifetime. Let's remember this as the 'R for Reliability'!

What are some common reasons that ICs fail due to reliability issues?

Great question! We will discuss several factors such as mechanical stress and thermal management that can impact reliability. Remember: Mechanical M for Stress and Thermal T for Management!

Can you explain a bit more about thermal management?

Of course! Thermal management involves controlling the heat within the IC package to prevent overheating. It’s vital for avoiding thermal stress—keep this in mind: Hot ICs = Hot Issues!

Factors Affecting Reliability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's talk about the factors affecting reliability. First up is mechanical stress. Can anyone give examples of mechanical stress in ICs?

Things like bending circuit boards or vibrations affect ICs, right?

Exactly! Such stresses can lead to micro-cracks or bond failures. Remember: Bending Boards = Breaking Bonds! Next, we'll look at thermal stress.

It's the heat and cooling cycles, right?

Yes, Student_1! Repeated temperature changes can lead to thermal fatigue. Remember this: Cycle of Heat = Cycle of Stress!

Moisture and Environmental Effects

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's shift gears and talk about moisture. What role does moisture play in IC packaging?

Moisture can damage the packaging, like causing corrosion, right?

Absolutely! Moisture can lead to delamination and corrosion of metal contacts. Keep in mind this phrase: Moisture = Destruction!

What materials are used to combat this moisture problem?

Good question, Student_3! Packaging materials must be designed to resist moisture, consider this: Right Material = Right Protection!

Testing Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s discuss testing and validation techniques. Has anyone heard of Accelerated Life Testing?

Is that where you speed up the testing process to simulate long-term use?

Exactly! This method helps identify potential failure modes quickly. Just remember: Accelerated Testing = Fast Insights!

What about moisture sensitivity testing?

Great point! It's about assessing how well IC packages withstand moisture exposure. Think of this: Moisture Test = Reliability Check!

Summary and Implications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To summarize our discussions today—what are the crucial factors for ensuring reliability?

Mechanical stress and thermal stress are key factors!

And moisture impacts the integrity of packaging materials!

Great job! Remember: Reliability hinges on design, material selection, and testing. Keep this knowledge in mind for real-world applications!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the significance of reliability in IC packaging, identifying factors such as mechanical and thermal stress, moisture, and material selection that impact performance. It also highlights testing and validation techniques crucial for ensuring longevity and robustness in packaged ICs.

Detailed

Reliability in IC Packaging

Reliability in integrated circuit (IC) packaging is a pivotal aspect that influences the overall performance and durability of semiconductor devices. An unreliable IC can lead to significant operational failures, adding high costs for repairs and impacting the reliability of electronic systems across various industries, including consumer electronics and automotive systems. This section outlines key factors affecting the reliability of IC packaging, including:

- Mechanical Stress: The impacts of thermal cycling, board flexing, and vibrations which may lead to delamination and cracking at critical junctures like the die-substrate interface.

- Thermal Stress: How temperature fluctuations can lead to over-heating and thermal fatigue, causing solder joint failures.

- Moisture and Environmental Factors: The degradation of IC packaging materials due to moisture absorption and corrosion, impacting electrical connections.

- Material Selection: The importance of choosing materials with suitable thermal conductivity, mechanical strength, and moisture resistance to enhance reliability.

The section also covers various testing and validation techniques for ensuring that IC packages meet reliability standards. Techniques such as Accelerated Life Testing (ALT), Moisture Sensitivity Testing, Mechanical Stress Testing, and non-destructive methods like X-ray and Acoustic Microscopy are discussed.

In conclusion, addressing these factors through careful design, quality control, and innovative materials can significantly improve the reliability of IC packages, ensuring they meet increasing industry demands.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Reliability in IC Packaging

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

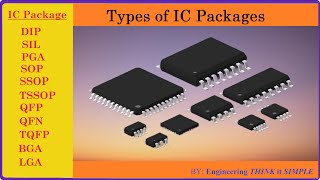

Reliability is a crucial consideration in the design and manufacturing of IC packages. An unreliable IC can lead to system failures, costly repairs, and compromised performance in a wide range of applications, from consumer electronics to automotive systems. IC packaging plays a vital role in ensuring that the packaged ICs function properly over their expected lifetime under various environmental conditions.

This chapter explores the key factors affecting the reliability of IC packaging, including material selection, mechanical stress, and thermal management, and outlines the common testing and validation techniques used to ensure the reliability of packaged ICs.

Detailed Explanation

Reliability in IC packaging refers to how well integrated circuits (ICs) can consistently perform without failure throughout their expected lifetime. It’s essential for both everyday devices, like smartphones, and critical systems, such as those used in cars or planes. The reliability of an IC depends on several factors, including how it's designed, the materials used for packaging, and the stress it endures during its life. Poor reliability can result in malfunctions that are costly to fix and can negatively impact performance.

Examples & Analogies

Imagine a smartphone that frequently crashes or fails to charge due to poor internal components and packaging. If the reliability of the IC packaging was ensured with good design and robust materials, the phone would work reliably, just as a well-built car needs reliable parts to run smoothly without breakdowns.

Factors Affecting Reliability in IC Packaging

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Several factors contribute to the reliability of IC packages. These factors must be carefully managed during the design and manufacturing stages to ensure that the IC can withstand mechanical stress, thermal cycling, moisture exposure, and other environmental influences.

Detailed Explanation

The reliability of ICs is influenced by various aspects: mechanical stress caused by handling and environmental changes, thermal stress resulting from temperature fluctuations, exposure to moisture, and the specific materials chosen for packaging. Each of these factors can introduce risks of failure, and understanding how to manage them is crucial during the IC design and manufacturing process.

Examples & Analogies

Think of a well-designed bridge. If the materials used are strong and suitable, and if it is built to withstand wind, water, and weight, it will last longer without collapsing. Similarly, when IC packages are designed to handle mechanical, thermal, and moisture-related stresses effectively, they are more reliable.

Mechanical Stress

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Mechanical stress is a key factor that impacts the reliability of ICs, especially when subjected to forces during handling, thermal expansion, or vibrations.

● Thermal Cycling: ICs experience thermal expansion when they heat up during operation and thermal contraction as they cool down. This constant expansion and contraction can lead to cracking or delamination of the packaging materials, particularly at the interfaces between the die and substrate or between the package and PCB.

● Board Flexing: During operation, the PCB can bend or flex, putting mechanical stress on the components, particularly the interconnects and bonding wires. This can lead to wire bond failures or micro-cracks in the solder joints.

● Vibration and Shock: In automotive, aerospace, and military applications, ICs are often subjected to vibrations and shocks. This can cause mechanical damage to the IC packaging, leading to solder joint fatigue or failure.

Detailed Explanation

Mechanical stress refers to the physical forces acting on IC packages, as they can impact performance and reliability. Thermal cycling means that as the IC heats up and cools down, it expands and contracts, which can crack or separate the materials. Board flexing happens when the circuit board bends, affecting the components attached to it. Vibration and shock, often experienced in vehicles or equipment, can further stress the packaging, leading to issues like cracks in solder joints that connect the IC to the circuit board.

Examples & Analogies

Consider how a metal spoon bends when you stir a hot soup. If you keep bending it, it can develop a crack and eventually break. Similarly, if IC packages undergo excessive mechanical stress, they may develop cracks or lose their connections, leading to failure.

Thermal Stress

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Thermal stress occurs when the IC undergoes temperature changes during operation. Inadequate heat dissipation or excessive temperatures can lead to failure modes such as melted solder, delamination, and die cracking.

● Thermal Fatigue: Repeated thermal cycles can lead to thermal fatigue in the solder joints or wire bonds, eventually causing cracks that compromise the electrical connection.

● Overheating: If the thermal management system of the IC package is not sufficient, overheating can cause the IC to operate outside its safe temperature range, leading to performance degradation or failure.

Detailed Explanation

Thermal stress arises from fluctuations in temperature while the IC operates. When the temperatures are not properly managed, they can cause materials to expand and contract, leading to issues like melting solder or cracks in the die. Thermal fatigue results from repeated heating and cooling, wearing down the connections. If the IC gets too hot without the proper cooling solutions, it can fail completely, which highlights the importance of adequate thermal management.

Examples & Analogies

Think about how a car engine can overheat if the cooling system isn’t working. If the engine gets too hot, it can lead to failure. Similarly, if an IC package does not have a good thermal management strategy, it can operate beyond its limits and break down.

Moisture and Environmental Factors

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Moisture and exposure to harsh environmental conditions can degrade the integrity of the IC package over time.

● Moisture Absorption: Many packaging materials, such as epoxy resins and solder balls, can absorb moisture from the environment. When these materials are heated during soldering or operation, the moisture can vaporize and cause delamination, package cracking, or wire bond failures.

● Corrosion: In humid or corrosive environments, corrosion can affect the metal contacts in the package, leading to oxidation or degradation of the electrical connections, especially in gold or copper wires or pads.

Detailed Explanation

Moisture and environmental conditions play a vital role in the reliability of IC packages. Some materials can absorb moisture, which can lead to significant issues during heating, as the vaporized moisture can cause cracking or detachment of components. Corrosive environments can lead to corrosion, affecting electrical connections and ultimately the IC’s performance. Therefore, ensuring that moisture-resistant materials are used is essential in protecting the integrity of the package.

Examples & Analogies

Think about how metal objects in a bathroom can rust due to humidity. A rusted metal will fail to support weight or conduct electricity efficiently. Similarly, moisture and corrosion can harm IC packages, leading to failures in electronic devices.

Material Selection

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The materials used in IC packaging, such as encapsulation resins, substrates, and interconnect materials, play a significant role in determining the reliability of the IC. Key factors to consider include:

● Thermal Conductivity: Materials with poor thermal conductivity can trap heat within the IC, leading to overheating and thermal stress. High-performance packages often use ceramic materials for their excellent thermal conductivity.

● Mechanical Strength: The mechanical properties of packaging materials must be considered to ensure that the IC can withstand external forces, such as vibrations, shocks, or bending, without suffering damage.

● Moisture Resistance: Packaging materials must be resistant to moisture absorption, especially in high-humidity environments, to prevent corrosion and delamination.

Detailed Explanation

Selecting the right materials is crucial for the reliability of IC packages. Good thermal conductivity ensures that heat dissipates quickly to avoid overheating. Mechanical strength is essential, as strong materials can endure stresses without failing. Additionally, materials must resist moisture to avoid deterioration over time. Evaluating these properties helps ensure that the IC performs reliably in various conditions.

Examples & Analogies

Imagine wearing a raincoat versus a regular coat in the rain. The raincoat protects you from getting wet, just like moisture-resistant packaging protects electronic components. Similarly, a sturdy raincoat helps you withstand strong winds and keep you warm, just as strong materials protect ICs from mechanical stresses.

Key Concepts

-

Reliability in IC packaging is crucial for preventing failures and maintaining performance.

-

Mechanical and thermal stresses can lead to physical damage in IC packages.

-

Moisture exposure is a significant risk factor affecting packaging integrity.

-

Proper material selection is vital for enhancing reliability in ICs.

-

Testing and validation techniques are essential for identifying potential failure modes.

Examples & Applications

Thermal cycling can cause cracks in solder joints due to repeated expansion and contraction.

Moisture absorption during the soldering process can lead to significant reliability issues such as delamination.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If you want reliability, take care of thermal and moisture, too; keep ICs strong for all they do!

Stories

Once upon a time, an IC lived happily until moisture came and caused it despair. It learned to stay dry, and the thermal stress it fought, and now in devices, it's prized and sought!

Memory Tools

R-M3: Reliability, Moisture, Mechanical Stress, and Thermal Management determine the health of ICs.

Acronyms

MHS

Moisture

Heat

and Stress contribute to reliability issues.

Flash Cards

Glossary

- Integrated Circuit (IC)

A set of electronic circuits on a small flat piece of semiconductor material, often used in various devices.

- Mechanical Stress

Forces that can cause deformation in IC packaging, leading to potential failures.

- Thermal Stress

Strain on IC materials due to temperature fluctuations during operation.

- Moisture Absorption

The process by which packaging materials take in moisture, potentially leading to degradation.

- Accelerated Life Testing (ALT)

A method used to simulate long-term stress on ICs over a shorter period.

- Delamination

Separation of layers in an IC package, often due to thermal or moisture stress.

Reference links

Supplementary resources to enhance your learning experience.