Mechanical Stress Testing

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Mechanical Stress Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we’re going to talk about mechanical stress testing. Can anyone tell me why this kind of testing is important for ICs?

It helps check if the IC can survive real-world conditions, right?

Exactly! We want to ensure ICs can handle mechanical forces without failing. One way we do this is through drop testing. Can someone explain what drop testing involves?

That's when you drop a device to see how the IC inside withstands the impact.

Correct! We evaluate the mechanical robustness this way. Let’s remember 'DROP' — it stands for 'Durability Resistance On Impact'.

Vibration Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss vibration testing. Does anyone know why this is crucial for certain industries?

It’s important for automotive or aerospace applications because those devices face a lot of vibration.

Exactly! Think of cars or airplanes facing bumps or turbulence. How can we design IC packages to endure such conditions?

By using more robust materials or ensuring better mechanical design?

Right! Good design and material choice are critical. Remember 'VIBE' for Vibration Integrity in Building Electronics.

Feedback and Key Takeaways

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To wrap up, can someone summarize why mechanical stress testing is crucial for IC reliability?

It helps identify weaknesses in designs before they are used in real applications.

Exactly! Both drop and vibration testing help improve the reliability of IC packages. Let’s remember: Reliable ICs = Happy Customers!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses mechanical stress testing, emphasizing its importance in evaluating the durability of integrated circuits (ICs). Key methods include drop testing and vibration testing, which help identify potential failure modes that could compromise the integrity of IC packages in real-world applications.

Detailed

Mechanical Stress Testing

Mechanical stress testing is a critical analytical approach within the realm of integrated circuit (IC) packaging reliability. This section specifically focuses on simulating the mechanical forces that ICs will encounter during their operational life. It includes various testing methods that help manufacturers identify and mitigate risks associated with mechanical stress.

- Drop Testing: This method is particularly relevant for consumer electronics where devices may be accidentally dropped. During drop tests, IC packages endure impacts that can reveal weaknesses in mechanical robustness and help evaluate durability.

- Vibration Testing: Essential for applications in automotive and aerospace, this testing simulates the stresses IC packages face from environmental factors like engine vibrations and road bumps. It’s crucial for ensuring that the packages can withstand the harsh conditions they may encounter in the field.

In both types of testing, data gathered allows engineers and manufacturers to improve design and material selection to enhance overall reliability.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Mechanical Stress Testing

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Mechanical stress testing simulates the forces that ICs will experience in their end-use environment. This includes shock, vibration, and bend testing.

Detailed Explanation

Mechanical stress testing is essential to ensure that integrated circuits (ICs) can endure the different forces they may encounter during their practical use. This testing method covers aspects such as shock from drops, vibrations from machinery, and bending that occurs due to movements or thermal expansion. By replicating these conditions in a controlled environment, manufacturers can determine the built quality and durability of the IC packages.

Examples & Analogies

Think of mechanical stress testing like a final exam for an athlete before a big competition. Just as the athlete needs to practice under various conditions to ensure they can handle the pressure and the competition, ICs need to be tested in various scenarios to ensure they can function properly under real-world stresses.

Drop Testing

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Drop Testing: In consumer electronics, ICs may be subjected to drop tests to simulate the forces experienced when a device is accidentally dropped. This helps evaluate the mechanical robustness of the IC package.

Detailed Explanation

Drop testing is specifically designed to simulate the impacts an IC might experience if a device containing it is dropped. During these tests, the IC packages are dropped from a certain height onto a solid surface to see if they can withstand the shock. The aim is to classify how well the ICs can protect their internal components and maintain functionality after such impacts. This is crucial for consumer electronics, where drops are common.

Examples & Analogies

Imagine dropping your smartphone accidentally. Drop testing makes sure that, just like how some phones come with a promise of being durable despite falls, the ICs inside are tested to ensure they don't fail or become damaged when subjected to similar situations.

Vibration Testing

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Vibration Testing: For automotive and aerospace applications, vibration tests simulate the stresses an IC package will experience due to engine vibration, road bumps, or aircraft turbulence.

Detailed Explanation

Vibration testing involves subjecting IC packages to controlled vibrations that mimic real-life situations, such as those encountered in cars, planes, or other machinery. This is vital in ensuring that the components within the IC remain intact when they are continuously exposed to vibrations over time. The test helps identify weaknesses that could lead to failures during normal operations, thus improving reliability in demanding environments.

Examples & Analogies

Consider how a car engine shakes when it runs. If parts inside the engine aren’t secured or designed well, they could break or malfunction. Similarly, vibration testing ensures that the ICs are sturdy enough to deal with the constant trembling they might face in a car or during flight, much like how engine components are rigorously tested.

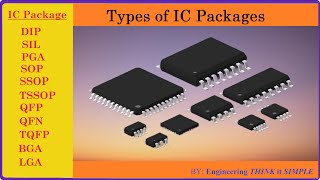

Key Concepts

-

Mechanical Stress Testing: A method to simulate forces on IC packages to evaluate their durability.

-

Drop Testing: Testing that evaluates the effects of impacts on ICs.

-

Vibration Testing: A method used to assess the endurance of ICs against oscillatory forces.

Examples & Applications

A smartphone is subjected to drop tests to ensure that the internal ICs remain functional after a typical fall.

Automotive ICs undergo vibration testing to simulate the conditions faced while driving on bumpy roads.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When your IC might fall, drop it and see, If it withstands the hit, it’s as strong as can be!

Stories

Imagine a smartphone surviving a drop from a table - the engineers designed it with drop testing to make sure it stays safe, no cracks or breaks allowed.

Memory Tools

D.R.O.P: Durability, Resistance, On, Impact - remember this for drop testing!

Acronyms

V.I.B.E

Vibration Integrity in Building Electronics - a reminder for considering vibration testing.

Flash Cards

Glossary

- Drop Testing

A testing method where electronic devices are dropped to assess the mechanical durability of the integrated circuits (ICs) within.

- Vibration Testing

A testing procedure that simulates environmental vibrations encountered in automotive or aerospace applications to evaluate IC reliability.

- Mechanical Stress

The forces exerted on IC packages that can result in physical damage if they exceed the material limits.

Reference links

Supplementary resources to enhance your learning experience.