Improving Reliability in IC Packaging

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Design for Reliability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, let's explore how the design phase of IC packaging impacts reliability. What do you think we should prioritize in this design process?

We should focus on using stronger materials!

And consider how it will react to heat and moisture!

Great points! Designing for reliability means focusing on thermal management and mechanical robustness. Remember the acronym 'DFM'—Design for Manufacturability, which includes reliability.

Are there specific materials we should always use?

Excellent question! Materials like ceramics are often used for their high thermal conductivity and strength. They play a vital role in minimizing thermal stress.

What about moisture?

Always consider moisture resistance when selecting materials. Moisture can lead to corrosion and failures in solder joints. Summarizing: prioritize strong, thermally efficient, and moisture-resistant materials in designs.

Quality Control and Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we need to focus on quality control in the manufacturing process. Can anyone tell me why this is important?

To make sure the ICs work well, right?

Yes! Testing helps us find flaws before they reach customers.

Exactly! Rigorous quality testing, like accelerated life testing or moisture sensitivity testing, helps identify weaknesses early. Remember 'ALT'—Accelerated Life Testing—which simulates long-term usage in a short timeframe.

What kinds of conditions do we test for?

We test for thermal cycling, humidity exposure, and mechanical stress. These tests ensure that the ICs can withstand their intended application environments.

How do we know when to re-test?

Continuously re-evaluate every design or material change. Summarizing: Implement must rigorous testing to ensure quality and reliability of ICs through methods like ALT.

Material Innovation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's dive into material innovation. How can new materials enhance reliability?

New materials might hold up better under stress!

And reduce overheating effects!

Absolutely! For example, high-performance ceramics offer excellent thermal conductivity, while moisture-resistant compounds can prevent package degradation. Remember the phrase 'Material Matters'—it does!

Are there specific examples of these materials?

Yes, advanced solder alloys are another great example, which can withstand higher temperatures and mechanical stresses. Materials can really make or break the reliability of the IC package.

So it's about choosing the right material for the job?

Exactly! Summarizing: Innovations in materials, including ceramics and new alloys, are key to improving IC packaging reliability.

Failure Analysis

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s discuss failure analysis. Why is it important in our reliability strategies?

It helps us find out why something went wrong!

So we can fix those issues in future batches, right?

Exactly! Conducting a thorough failure analysis allows us to identify the root causes of failures and prevent similar issues from occurring in future manufacturing. Keep in mind the acronym 'FMEA'—Failure Mode and Effects Analysis—to understand the impacts of failures.

What steps should we take during a failure analysis?

We should review the testing data, inspect the materials used, and analyze the manufacturing processes. Summarizing: Effective failure analysis is crucial for continuous improvement in reliability.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

To enhance the resilience of IC packaging, it is crucial to implement design strategies that prioritize reliability, conduct rigorous testing during manufacturing, innovate materials to withstand environmental stresses, and undertake detailed failure analyses. By addressing these areas, manufacturers can significantly reduce the risk of failures in IC packages.

Detailed

Improving Reliability in IC Packaging

Reliability in integrated circuit (IC) packaging is vital to ensure the functionality and longevity of electronic systems. This section highlights several strategies to enhance IC packaging reliability:

- Design for Reliability: When designing IC packaging, it is essential to prioritize materials and structures that can endure thermal cycling, moisture, and mechanical stress. Proper thermal management techniques and mechanical robustness need to be integral to the design process.

- Quality Control and Testing: Implementing rigorous testing protocols, including accelerated life testing and moisture sensitivity testing, is crucial in the manufacturing process to guarantee that only the most reliable ICs reach the market. This aids in identifying potential failures before they occur in real-world scenarios.

- Material Innovation: Advancements in packaging materials, such as high-performance ceramics, moisture-resistant compounds, and advanced solder alloys, are critical in improving the reliability of IC packages. These materials can significantly mitigate risks associated with environmental stressors.

- Failure Analysis: In cases of IC failure, conducting thorough failure analyses helps identify the root cause and develop solutions to avoid similar issues in future production batches. This continuous improvement cycle is vital for the long-term reliability of IC packaging.

By integrating these strategies, manufacturers can enhance IC packaging reliability significantly, leading to better performance and reduced failure rates in various applications, including consumer electronics and automotive systems.

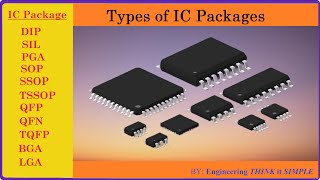

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Design for Reliability

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Design for Reliability: IC packaging should be designed with materials and structures that can withstand thermal cycling, moisture, and mechanical stress. Careful thermal management and mechanical robustness should be prioritized in the design phase.

Detailed Explanation

Design for Reliability means creating IC packages that can endure different challenges like temperature changes, moisture, and physical stress during their lifespan. It's crucial to choose the right materials and create structures that support the package's performance under such conditions. This approach involves thinking ahead about how the IC will be used and making decisions during the design phase that prioritize durability.

Examples & Analogies

Imagine designing a bridge. An engineer must ensure that the materials used can handle heavy loads and extreme weather conditions over time. Similarly, when designing IC packages, the engineers must ensure that they can survive temperature fluctuations and other stressful conditions.

Quality Control and Testing

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Quality Control and Testing: Rigorous testing and validation, such as accelerated life testing and moisture sensitivity testing, should be integrated into the manufacturing process to ensure that only reliable ICs are delivered to customers.

Detailed Explanation

Quality Control and Testing involves establishing a thorough process to verify that IC packages meet performance specifications before they reach customers. Accelerated life testing simulates long-term conditions to identify any potential issues more quickly. Moisture sensitivity testing checks how packaging materials react to humidity. By embedding these tests into manufacturing, we can catch and address reliability issues early.

Examples & Analogies

Think of quality control like a teacher grading homework. The teacher checks each assignment for errors or misunderstandings before handing them back. If the teacher skips this step, students may struggle later. In manufacturing, testing ensures that ICs won't fail when they’re actually in use.

Material Innovation

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Material Innovation: The development of new packaging materials, such as high-performance ceramics, moisture-resistant compounds, and advanced solder alloys, can significantly improve the reliability of IC packages.

Detailed Explanation

Material Innovation focuses on finding and using new types of materials that offer better performance for IC packaging. For example, high-performance ceramics can provide better heat dissipation compared to traditional materials. Similarly, moisture-resistant compounds help prevent damage from humidity. This innovation is critical because using the right materials can lead to longer-lasting IC packages.

Examples & Analogies

Consider smartphones, which often use advanced materials like Gorilla Glass for screens. This technology helps make the screens more durable and resistant to scratches and drops. In the same way, new materials in IC packaging help electronics perform better.

Failure Analysis

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Failure Analysis: In the event of a failure, a thorough failure analysis should be conducted to understand the root cause and prevent similar issues in future batches.

Detailed Explanation

Failure Analysis involves investigating failures to determine what went wrong in IC packaging. This process includes examining the design, materials, and manufacturing methods to find the source of the problem. Once the root cause is identified, steps can be taken to prevent those issues in future production runs, leading to greater reliability overall.

Examples & Analogies

Imagine you’ve baked a cake that didn’t rise. You would look back at your recipe and process to figure out if it was undercooked, if you missed an ingredient, or if the oven temperature was incorrect. Similarly, in failure analysis, engineers dissect the problem to learn and improve future outcomes in IC packaging.

Key Concepts

-

Design for Reliability: Prioritizing materials and structures that can withstand environmental stresses in IC packaging.

-

Quality Control: Implementing rigorous testing to ensure reliability before products reach the market.

-

Material Innovation: Utilizing advanced materials to enhance the durability and performance of IC packages.

-

Failure Analysis: Conducting thorough investigations of failures to improve future designs and manufacturing processes.

Examples & Applications

Using advanced ceramics in IC packaging can improve thermal conductivity and reduce overheating risks.

Moisture-resistant compounds can prevent corrosion, enhancing package integrity in humid environments.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When it comes to packaging, be wise, design for reliability, the prize!

Stories

Once in a land of electronics, a crafty inventor built an IC that failed due to weak packaging. From then, he learned to choose materials wisely and conducted tests to avoid mishaps, becoming the champion of reliability.

Memory Tools

Remember 'R-MAT-F': Reliability, Materials, Analysis, Testing - these are key strategies for improving IC packaging.

Acronyms

DFM

Design for Manufacturing—key to ensuring designs reflect reliability.

Flash Cards

Glossary

- Design for Reliability

A strategy to create IC packaging that can withstand environmental and mechanical stresses effectively.

- Quality Control

The process of ensuring that manufactured ICs meet specified reliability standards through rigorous testing.

- Material Innovation

The introduction of new materials to improve the reliability of IC packaging, such as advanced ceramics and resistance compounds.

- Failure Analysis

An examination of failed ICs to determine the root causes of failures and prevent future occurrences.

- Accelerated Life Testing (ALT)

A testing method that simulates long-term environmental effects on ICs in a shorter time frame.

- FMEA

Failure Mode and Effects Analysis; a systematic method for evaluating potential failures and their impacts.

Reference links

Supplementary resources to enhance your learning experience.