Moisture and Environmental Factors

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Moisture Effects on IC Packages

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're exploring the effects of moisture on integrated circuit packages. Can anyone tell me what happens to IC packages when they absorb moisture?

I think the moisture can cause damage when the package is heated?

Exactly! When the packaging materials absorb moisture and are heated during soldering or normal operation, the moisture can vaporize. This leads to problems like delamination.

What does delamination mean in this context?

Good question! Delamination refers to the separating of layers within the package material, which can compromise its structural integrity.

So, is moisture the only environmental factor we need to worry about?

Not at all! Corrosion in humid or corrosive environments is another significant concern, often impacting metal contacts. Let’s discuss corrosion next.

How does corrosion affect the IC package specifically?

Corrosion can lead to oxidation of metal contacts, degrading electrical connections and possibly causing device failure. Understanding these effects helps when designing reliable IC packages.

In summary, moisture absorption and corrosion are critical environmental factors that can lead to significant reliability issues in IC packaging.

Preventing Moisture-Related Issues

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand moisture and corrosion, what can we do to prevent these issues in IC packaging?

Maybe we could choose materials that don’t absorb moisture easily?

Correct! Selecting moisture-resistant materials is a great first step. It’s crucial to consider materials that have low moisture absorption.

What about the packaging process itself? Can that help reduce moisture issues?

Yes, excellent point! Proper sealing and environmental control during the packaging process are essential to minimize moisture exposure.

Can testing for moisture sensitivity help prevent these problems in the first place?

Absolutely! Conducting moisture sensitivity testing can provide valuable insights into how much moisture a package can handle before failing.

So we can design IC packages to withstand harsh environments?

Exactly! By addressing both moisture and potential corrosive factors during design, we can significantly improve reliability. Great engagement today! Make sure to review these concepts before our next class.

Real-World Implications of Moisture Issues

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss the real-world implications of moisture issues in IC packages. Why do you think this is important?

Because it can lead to device failures in everyday products, right?

Absolutely! Consider consumer electronics, automotive systems, and medical devices; failures due to moisture can result in not just performance issues but also safety concerns.

Isn’t there a cost aspect as well?

Yes! Unreliable ICs can lead to costly recalls and repairs, which is critical for manufacturers. So making reliable packages helps maintain brand integrity.

Could customer dissatisfaction lead to long-term effects on businesses?

Definitely, and that’s why continuous improvements in material science and rigorous testing for moisture resistance are cornerstones of effective IC packaging.

So focusing on prevention is really worth it?

Absolutely! Investing in preventive measures is crucial for ensuring device longevity and customer satisfaction. Excellent discussion today!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses how moisture absorption and corrosion in various environmental conditions degrade the IC package over time. It highlights the importance of carefully managing these factors during the IC packaging process to ensure long-term reliability.

Detailed

Moisture and Environmental Factors

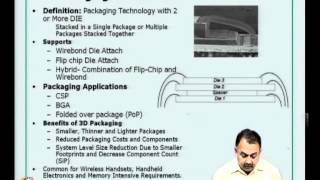

Moisture and exposure to harsh environmental conditions can degrade the integrity of IC packages over time. Moisture Absorption occurs when many packaging materials, like epoxy resins and solder balls, absorb moisture from the environment. When heated during soldering or operation, this absorbed moisture can vaporize, causing issues like delamination, package cracking, or wire bond failures.

Corrosion is another critical factor, particularly in humid or corrosive environments, where it can affect the metal contacts in the package. This degradation can lead to oxidation and compromised electrical connections, specifically in materials such as gold or copper wires.

Understanding these moisture-related reliability issues is vital for IC packaging design, as it forms a crucial part of ensuring that packaged ICs maintain functionality throughout their intended lifespan.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Moisture Absorption

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Many packaging materials, such as epoxy resins and solder balls, can absorb moisture from the environment. When these materials are heated during soldering or operation, the moisture can vaporize and cause delamination, package cracking, or wire bond failures.

Detailed Explanation

Moisture absorption happens when certain materials used for packaging ICs (like epoxy resins and solder balls) take in water vapor from their surroundings. When these materials are subsequently heated, as they would during soldering or regular operation, the moisture turns into steam. This steam can create pressure within the materials, leading to separation of layers (delamination), cracks in the package, or failure of wire bonds that connect components together. This highlights the importance of properly managing the moisture levels in environments where these components are manufactured and used to ensure reliability.

Examples & Analogies

Think of it like a sponge soaking up water. If you heat that sponge, the water inside turns into steam and tries to escape. Just like with the IC packaging materials, this can create damage and weaken the structure if the 'sponge' isn't able to release the steam safely.

Corrosion

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In humid or corrosive environments, corrosion can affect the metal contacts in the package, leading to oxidation or degradation of the electrical connections, especially in gold or copper wires or pads.

Detailed Explanation

Corrosion is a chemical process that occurs when metal is exposed to moisture and certain environmental conditions, leading to its deterioration. In the context of IC packaging, metals like gold or copper can oxidize when moisture interacts with them, diminishing their ability to conduct electricity effectively. This degradation of the electrical connections can lead to poor performance or complete failure of the IC. Managing environments to be less humid or corrosive can prevent such issues.

Examples & Analogies

Consider leaving a bicycle out in the rain. Over time, rust (a type of corrosion) can build up on the metal parts, making it harder to ride. Similarly, if IC packages are not protected from humidity, the metal connections inside can 'rust' and fail, leading to a malfunctioning device.

Key Concepts

-

Moisture Absorption: The uptake of moisture by packaging materials affecting their integrity and performance.

-

Delamination: The separation of layers in IC packaging leading to failures.

-

Corrosion: The degradation of metal contacts due to chemical reactions in humid environments.

Examples & Applications

Example 1: An epoxy resin that swells when absorbing moisture, leading to package cracking during operation.

Example 2: Copper wires in a humid environment oxidizing, resulting in electrical resistance and eventual failure of the IC.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In ICs, moisture might seep, causing failures that make you weep.

Stories

Imagine a circuit board left out in the rain. Over time, rust forms on the connections, leading to a failure that stops the device from working. This highlights how important it is to manage moisture.

Memory Tools

M-C-D: Moisture Can Deteriorate. Remembering that moisture causes issues can help engineers prevent failures.

Acronyms

MICE

Moisture Induces Corrosion Effects. This helps recall the impacts of moisture in design considerations.

Flash Cards

Glossary

- Moisture Absorption

The process by which packaging materials take in moisture from the environment, impacting their integrity.

- Delamination

The separation of layers within packaging materials, which can lead to structural failures.

- Corrosion

The deterioration of metal contacts in a package due to chemical reactions, often exacerbated by moisture.

Reference links

Supplementary resources to enhance your learning experience.