Basics of Robot Motion and Manipulation

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Types of Robot Motion

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome class! Today, we're diving into the types of robot motion: joint space and Cartesian space. To begin, can anyone explain what joint space motion refers to?

Isn't that when we describe motion in terms of joint angles?

Exactly! Joint space motion uses the angles of joints or positions of actuators to determine the movement. This is especially useful for articulated arms. Now, can someone tell me what Cartesian space motion is?

I think it’s when we define the movement based on the position and orientation of the end-effector in 3D space.

Great job! Cartesian space motion allows us to specify tasks more intuitively, like pick-and-place actions. Remember, a good acronym to remember the two types is J-C: Joint Space and Cartesian space. Can anyone name other methods of motion like interpolation?

Linear and circular interpolation?

Absolutely! Linear interpolation is a straight-line movement and circular interpolation follows a curved path. These are prominent in applications like welding. To summarize this session, we discussed joint space and Cartesian space motion and the types of interpolation used in robotics.

Degrees of Freedom (DOF)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's move on to Degrees of Freedom, or DOF. Can anyone tell me what this term means?

Isn't it the number of independent movements a robot can make?

Exactly! For a robot to operate effectively, especially in 3D space, it typically needs 6 DOF. What do you think these six DOF consist of?

Three for position and three for orientation?

Right again! Each joint contributes to the robot's total DOF. For example, a revolute joint allows rotation which gives it one DOF. Can anyone think of how DOF affects robot design in civil engineering?

Maybe it's important for tasks like bricklaying where movements must be accurate.

Spot on! Evaluating mobility and designing mechanisms like robotic arms requires understanding DOF. Terme to help you remember: 'Six Mighty Directions' for six degrees of freedom. So to recap, we explored DOF's importance in robotic design and task execution.

Kinematics of Robot Manipulators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's get into the kinematics of robot manipulators. First up, who can explain forward kinematics?

That's when you determine the end-effector's position and orientation based on joint parameters, right?

Nice work! It's all about understanding the kinematic chain and how links and joints interact. What do we use to model these relationships?

I think it’s transformation matrices like the Denavit–Hartenberg parameters?

Correct! Now, flipping the scenario, what do we mean by inverse kinematics?

That’s when we figure out what joint parameters are needed to achieve a desired end-effector position?

Yes! It can often yield multiple or no solutions, making it more complex than forward kinematics. To summarize, we covered the key concepts of forward and inverse kinematics and their significance in controlling robotic movements.

Motion Control Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss motion control techniques next. Does anyone know the difference between open-loop and closed-loop control?

Open-loop doesn’t use feedback, while closed-loop does!

Exactly! Open-loop control is simpler and cost-effective but less accurate. Closed-loop is better for precision because it adjusts based on sensor data. Can someone share an example of where we might use these in construction?

Maybe in automated bricklaying where precision is critical, closed-loop control would be preferred?

Great example! Motion controllers also implement various control laws for effective operation. Let's remember 'Open and Shut,' to separate the two types of control in our minds. We concluded our session by outlining open-loop and closed-loop control advantages, especially in the context of robotics.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section introduces key concepts related to robot motion, such as joint space and Cartesian space motion, degrees of freedom, kinematics, control techniques, and applications in civil engineering. These concepts form the basis for designing and controlling robotic systems that assist in various tasks, particularly in construction.

Detailed

Detailed Summary

This section delves into the essential aspects of robot motion and manipulation, discussing the fundamental principles required for understanding robotic systems.

Types of Robot Motion

- Joint Space Motion: Involves movement defined by the angles of joints, crucial for articulated arms and manipulators.

- Cartesian Space Motion: Targets the position and orientation of the end-effector in a 3D Cartesian coordinate system, making task specification intuitive.

- Linear and Circular Interpolation: Techniques for moving the end-effector along straight lines or arcs, often critical in industrial tasks like welding.

Degrees of Freedom (DOF)

DOF is a measure of the number of independent movements a robot can perform, necessary for evaluating mobility and designing effective robotic systems, particularly in construction robotics.

Kinematics and Dynamics

- Forward Kinematics: This determines the end-effector’s position based on joint parameters, using transformation matrices.

- Inverse Kinematics: In contrast, it calculates needed joint parameters to achieve a desired end-effector position, often with non-unique solutions.

Control Techniques

Different motion control techniques, including open-loop (without feedback) and closed-loop (with feedback), play important roles in robot operations.

This foundational knowledge is crucial for applications in civil engineering, enabling robots to perform sophisticated tasks such as automated bricklaying, 3D concrete printing, and more.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Robot Motion and Manipulation

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

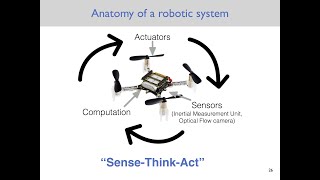

Chapter Content

In the realm of robotics and automation, motion and manipulation form the core aspects that enable a robot to interact with its environment. Unlike static machines, robots are expected to perform physical tasks, which involve moving through space, adjusting their configurations, and manipulating objects using tools or end-effectors. This chapter introduces the fundamental principles and mathematical tools required to model, describe, and analyze robotic motion and manipulation. These foundations are essential for designing, simulating, and controlling robotic systems, especially in industrial and construction applications within Civil Engineering.

Detailed Explanation

This chunk introduces us to the essential concepts of how robots move and interact with their surroundings. Unlike traditional machines that do not move, robots must perform tasks that involve movement and manipulation. This includes changing their positions in space, adjusting their joints, and handling various objects using specialized tools. The chapter will cover the basic principles and mathematical tools necessary for understanding and analyzing these movements, which are crucial in fields like construction and industrial automation.

Examples & Analogies

Think of a robot like a human worker on a construction site. Just as a worker needs to move around, reach for tools, and lift materials, robots need to do the same to complete their tasks effectively.

Types of Robot Motion

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

9.1 Types of Robot Motion

9.1.1 Joint Space Motion

- Refers to motion described by the angles of joints or positions of actuators.

- Each joint has its own coordinate; motion planning here involves computing trajectories in joint space.

- Typically used for articulated arms and manipulators.

9.1.2 Cartesian Space Motion

- Motion described in terms of the position and orientation of the end-effector in 3D space (X, Y, Z axes).

- More intuitive for specifying tasks like pick-and-place.

- Requires inverse kinematics to convert to joint-level commands.

9.1.3 Linear and Circular Interpolation

- Linear Interpolation: End-effector moves along a straight line.

- Circular Interpolation: Movement along a circular arc, often used in welding or painting applications.

Detailed Explanation

This section explains different types of motion that robots use. Firstly, joint space motion refers to how robots move based on the angles of their joints. For example, a robot arm moves by adjusting its joints to reach a specific position. Secondly, Cartesian space motion is based on where the robot's end-effector (like a hand) is positioned in 3D space, providing a more intuitive way to set tasks like picking up objects. Lastly, interpolation methods describe how a robot can smoothly move between points. Linear interpolation is a straight path, while circular interpolation creates circular arcs, useful in tasks like welding where precision along a curve is required.

Examples & Analogies

Consider a robotic arm in a factory. When it adjusts its joints (joint space), it’s like a person bending their arm to pick up a box. If the robot instead needs to move straight to a target (Cartesian space), it would be similar to walking directly to a destination without detours. Linear and circular interpolation methods can be likened to drawing lines and curves on paper – robots need to know how to 'draw' their paths effectively.

Degrees of Freedom (DOF)

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

9.2 Degrees of Freedom (DOF)

- Represents the number of independent movements a robot can perform.

- For rigid bodies in 3D space, 6 DOF are typically required (3 for position, 3 for orientation).

- Each joint contributes to DOF:

- Revolute Joint: 1 DOF (rotation)

- Prismatic Joint: 1 DOF (translation)

- DOF analysis is essential for:

- Evaluating mobility

- Designing mechanisms for construction robotics, e.g., robotic arms for bricklaying or welding.

Detailed Explanation

Degrees of Freedom (DOF) indicate how many ways a robot can move. In three-dimensional space, a robot needs six degrees of freedom—three for moving up/down and left/right (position) and three for tilting and rotating (orientation). Each joint on the robot contributes to this count; for example, a revolute joint allows rotation, adding one DOF, while a prismatic joint enables sliding motion, also adding one DOF. Understanding DOF is vital for assessing how flexible and capable a robot can be in performing tasks, especially in sectors like construction where different movements are needed.

Examples & Analogies

Imagine trying to build a structure with a robotic arm. If the arm can only move in two directions (like a toy robot with limited joints), it can’t reach all the spots needed for building. Now think of a human who can reach in various directions, twist their torso, and bend down. This is similar to a robot with six degrees of freedom, providing it with the ability to navigate and work in complex environments.

Kinematics of Robot Manipulators

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

9.3 Kinematics of Robot Manipulators

9.3.1 Forward Kinematics

- Determines position and orientation of the end-effector given joint parameters.

- Based on the kinematic chain of links and joints.

- Uses transformation matrices (Denavit–Hartenberg parameters) to model link relationships.

9.3.2 Inverse Kinematics

- Determines the required joint parameters to achieve a desired end-effector position.

- Often results in multiple or no solutions.

- Nonlinear and more computationally complex than forward kinematics.

Detailed Explanation

Kinematics studies the movement of robots without considering the forces involved. Forward kinematics is used to find out where the robot's end-effector is located based on the positions of its joints. This helps in figuring out where the robot needs to go to reach a target position. Inverse kinematics, on the other hand, deals with finding the necessary joint angles required to achieve that target position. It’s often more complicated because many joint configurations can lead to the same position, or some positions might not be reachable at all.

Examples & Analogies

Think of a robotic arm trying to grab a pen from a table. Using forward kinematics is like having a map showing the pen's location and figuring out how the arm will move to get there. Inverse kinematics is akin to asking ‘how do I need to position my joints and segments to reach that pen?’ – the challenge is that there might be many different configurations to achieve the same outcome, just like how people can stretch their arms in various ways to pick something up.

Key Concepts

-

Joint Space Motion: Refers to motion described by joint angles or positions.

-

Cartesian Space Motion: Describes motion in a 3D coordinate system like pick-and-place tasks.

-

Degrees of Freedom (DOF): Represents independent movements; crucial for robotic design.

-

Kinematics: Study of motion focused on enabling and analyzing robotic movements.

-

Forward Kinematics: Establishes end-effector position from joint parameters.

-

Inverse Kinematics: Determines joint parameters needed for a specific end-effector position.

-

Motion Control: Techniques influencing how effectively a robot moves and responds.

Examples & Applications

Joint Space Motion is utilized in robotic arms that operate in assembly lines, where joint angles are crucial to reach specific positions.

Cartesian Space Motion is evident in 3D printing applications, where the position of the print head is critical for accurate layer placement.

The automated bricklaying robot employs precise DOF to manipulate bricks while ensuring accurate placement and alignment.

Forward Kinematics applies in robotic surgery where it calculates the position of tools based on the movements of a surgical robot.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In Joint Space, angles are king, in Cartesian, position's the thing!

Stories

Imagine a robot in a factory; its arms move like dancers, angles leading, positions guiding.

Memory Tools

Remember 'D-J-C' for Degrees of Freedom, Joint Space, and Cartesian Space.

Acronyms

Use 'K-I-K' for Kinematics

Inputs lead to Kinematic chains

and Kinematic outputs!

Flash Cards

Glossary

- Joint Space Motion

Motion described by the angles of joints or positions of actuators.

- Cartesian Space Motion

Motion defined in terms of the position and orientation of the end-effector in three-dimensional space.

- Degrees of Freedom (DOF)

The number of independent movements a robot can perform; generally requires six DOF in 3D space.

- Kinematics

The study of motion without regard to the forces that cause it, focusing on the spatial relationships of moving parts.

- Inverse Kinematics

The process of determining the joint parameters required to achieve a desired position of the end-effector.

- Forward Kinematics

The calculation of the position and orientation of the end-effector based on joint parameters.

- Motion Control

The technique employed to move a robot or mechanism in a desired manner.

- Interpolation

The method of estimating intermediate values between known values in motion paths.

Reference links

Supplementary resources to enhance your learning experience.