Soft Robotics in Confined Tunnel Spaces

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Soft Robotics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to learn about soft robotics, which is a crucial innovation in the field of tunneling. Can anyone tell me what soft robots are made out of?

Are they made of flexible materials like rubber and silicone?

Exactly! Soft robots are made from compliant materials allowing them to adapt their shape. This makes them useful in confined spaces. Why do you think that flexibility is important in tunneling?

Because tunnels often have tight and irregular spaces?

Right! This adaptability helps them navigate challenging environments safely. Remember, flexible materials = safe navigation. Let's move on to how these robots operate in different situations.

Advantages of Soft Robotics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's delve into the advantages of soft robotics. Soft robots can safely interact with human workers. What do you think this means for safety in tunnels?

It means there's less risk of accidents because the robots can do tasks that would be dangerous for humans.

Exactly! Soft robots reduce human exposure to dangers like toxic gases or collapsing structures. Can anyone give me examples of where these have been applied?

I think they can be used for pipe inspection and environmental sensing?

That's right! Soft robots are used for inspecting pipes, conducting non-destructive tests, and environmental monitoring. Remember the acronym PENS for Pipe inspection, Environmental sensing, and Non-destructive testing!

Applications of Soft Robotics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's explore the applications of soft robotics in tunneling. Who can tell me one application?

Pipe inspection!

Correct! They can facilitate inspections that traditional robots might struggle with. What else?

Non-destructive testing?

Yes! Non-destructive testing is crucial to assess the integrity without causing additional damage. Soft robots also excel in environmental sensing in hazardous zones. How does this benefit construction activities?

It helps keep workers safe by monitoring potential hazards.

Spot on! Integrating these robots improves safety and efficiency in underground construction. So remember PENS and think of how essential soft robotics are in modern tunneling processes.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the concept of soft robotics, emphasizing its advantages in navigating limited and hazardous underground environments. It highlights specific applications such as pipe inspection, non-destructive testing, and environmental sensing in dangerous areas.

Detailed

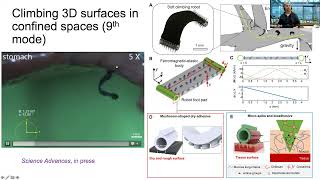

Soft Robotics in Confined Tunnel Spaces

Overview

Soft robotics refers to robotic systems constructed from compliant materials like silicone, rubber, or shape memory alloys. These materials allow robots to bend, twist, and adapt their shape, making them particularly effective in specialized applications such as tunneling and confined spaces.

Importance in Underground Environments

Soft robots are designed to navigate tight or irregularly shaped spaces that are often encountered in underground construction. This flexibility enables soft robots to safely interact with human workers and delicate surfaces while maintaining functionality in potentially hazardous conditions. Their ability to squeeze through debris, cavities, and inspection ducts creates opportunities for enhanced monitoring and logistics in tunnel operations.

Applications in Tunneling

Soft robotics finds valuable applications in several key areas within tunneling operations:

- Pipe Inspection and Micro-Tunneling Exploration: Soft robots can traverse narrow pathways to effectively assess pipe integrity and facilitate the micro-tunneling process.

- Non-destructive Testing: They can perform inspections that do not compromise structural integrity, offering insights into component conditions without physical damage.

- Environmental Sensing: In dangerous areas susceptible to gas leaks or varying temperatures, soft robots can monitor environmental conditions, providing critical data for safety assessments.

Overall, integrating soft robotics into confined tunnel spaces optimizes operational efficiency and enhances safety, addressing the unique challenges of subterranean projects.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

What are Soft Robots?

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Constructed using compliant materials like silicone, rubber, or shape memory alloys.

• Capable of bending, twisting, or adapting their shape.

Detailed Explanation

Soft robots are designed with flexible materials that allow them to move and change shape without rigid parts. This capability enables them to adapt to various environments and tasks, making them suitable for delicate operations where rigidity could cause damage. Materials such as silicone and rubber provide the necessary flexibility, while innovations like shape memory alloys allow robots to alter their form based on environmental conditions.

Examples & Analogies

Think of soft robots like an octopus. Just as an octopus can squeeze into tight spaces and manipulate objects thanks to its soft, flexible body, soft robots can move through narrow tunnels and adapt their shape to navigate complex environments.

Advantages in Underground Environments

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Navigate tight or irregularly shaped spaces.

• Safe interaction with human workers and delicate surfaces.

• Can squeeze through debris, cavities, and inspection ducts.

Detailed Explanation

In confined spaces, such as underground tunnels, traditional robots often struggle due to their rigid structures. Soft robots, however, can maneuver through these challenging environments with ease. Their flexibility allows them to navigate tight corners and crowded areas without causing harm to themselves, their environments, or any personnel nearby. This adaptability also enables soft robots to reach locations that might be hazardous or unreachable by humans, ensuring safety and efficiency in inspections and repairs.

Examples & Analogies

Imagine trying to get through a crowded subway station during rush hour. A rigid robot would struggle to move through the crowd, while a soft robot could easily weave its way through, much like a person gently pushing their way through the masses without causing disruption.

Applications

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Pipe inspection and micro-tunneling exploration

• Non-destructive testing

• Environmental sensing in dangerous areas (gas leaks, thermal zones)

Detailed Explanation

Soft robots have diverse applications in construction and maintenance tasks within tunnels. They can be used for pipe inspections, ensuring the condition of underground utilities is monitored without causing damage to the pipes themselves. Additionally, in micro-tunneling operations, soft robots can provide a less invasive option for exploration and excavation. Non-destructive testing is another area where they excel, as they can assess the integrity of structures without compromising them. Lastly, soft robots are equipped to sense environmental conditions in hazardous locations, detecting issues like gas leaks or temperature changes that could pose risks to human workers.

Examples & Analogies

Think of soft robots as specialized inspectors equipped like detectives. Just like a detective can carefully investigate a scene to gather clues without disturbing evidence, soft robots can analyze underground conditions or structures while ensuring that they don’t cause harm or damage.

Key Concepts

-

Soft Robotics: Robotics utilizing flexible, compliant materials to create adaptive machines.

-

Applications: Utilization of soft robots in specific tasks such as pipe inspection and environmental monitoring.

-

Advantages: Providing safe interaction with humans, capable of navigating irregular spaces.

Examples & Applications

Soft robots are able to fit through narrow gaps in tunnels or around obstacles that rigid robots cannot.

In an emergency situation involving gas leaks, soft robots can safely navigate into the area to gather data.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Soft and flexible, robots like to bend, in tunnels and pipes, they’re any engineer’s friend.

Stories

Once upon a time in a tight tunnel deep, soft robots roamed where the hard ones would weep. They squeezed through the gaps, and inspected with care, ensuring the safety of workers who were everywhere.

Memory Tools

PENS: Pipe inspection, Environmental soundings, Non-destructive tests, Safe workers. Helps remember uses of soft robots!

Acronyms

SRA - Soft Robotics Applications

for Safety

for Reliability

for Adaptability.

Flash Cards

Glossary

- Soft Robotics

A field of robotics focused on constructing robots from compliant materials, enabling flexibility and adaptability.

- Compliant Materials

Materials such as silicone and rubber that allow for bending, twisting, and shape adaptation.

- Nondestructive Testing (NDT)

Assessment methods that evaluate material properties without causing damage to the tested material.

- Environmental Sensing

The use of sensors to monitor conditions in an environment, such as detecting gas leaks or temperature variations.

- Microtunneling

A trenchless method of installing underground pipes using a small diameter tunneling machine.

Reference links

Supplementary resources to enhance your learning experience.