Comparison: Chemical vs. Mineral Admixtures

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Nature of Admixtures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will explore the different types of admixtures in concrete. Can anyone tell me what admixtures are?

I think admixtures are materials added to concrete to enhance its properties.

Great! There are two main types of admixtures: chemical and mineral. Chemical admixtures are typically organic or inorganic materials, while mineral admixtures are finely divided solids, often called supplementary cementitious materials (SCMs).

Could you give an example of both types?

Of course! An example of a chemical admixture is a superplasticizer, while a mineral admixture could be fly ash. Remember the acronym 'C-M', where C stands for Chemical and M for Mineral.

What do these two types do exactly?

Chemical admixtures modify short-term properties like workability, while mineral admixtures enhance long-term durability and sustainability. This differentiation is essential when selecting admixtures for concrete.

So, is it always better to use mineral admixtures because they improve sustainability?

Good point! Mineral admixtures help sustainability, but the choice between them depends on project requirements. Let’s summarize: Chemical admixtures focus on immediate effects, whereas mineral admixtures improve long-term performance.

Dosage and Timing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss the dosage of these admixtures. Does anyone remember the typical dosage of chemical admixtures?

Is it less than 5% of the cement weight?

Correct! Now, what about mineral admixtures?

They can range from 5% up to 50% of cement weight.

Exactly! This difference in dosage is crucial for understanding their applications. Why do you think the timing of usage is also a factor?

Maybe it’s because chemical admixtures are used to control the setting and workability?

Precisely! Chemical admixtures help control short-term behaviors, while mineral admixtures are integrated into the mix for long-term strength. Remember this by focusing on 'short' for chemical and 'long' for mineral.

That makes it clear! So timing affects what properties we can modify.

Great conclusion! Always consider the timing and dosage when designing concrete mixes.

Function and Cost

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we’ll discuss the functions and costs associated with each type of admixture. Who wants to share what functions our admixtures serve?

Chemical admixtures are for modifying workability and setting times.

And mineral admixtures improve strength and durability.

Correct! Also, note that chemical admixtures generally come with a higher cost due to their specialized nature. Why do you think mineral admixtures are usually cheaper?

Because they often reuse by-products from other industries, reducing costs.

Exactly! This makes them not just economical but also more environmentally friendly. Let’s summarize this topic: Chemical admixtures enhance short-term properties and are more expensive, while mineral admixtures improve long-term performance and are usually cheaper.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The comparison between chemical and mineral admixtures reveals that while chemical admixtures primarily modify the short-term properties of concrete such as workability and setting time, mineral admixtures enhance long-term attributes like strength and durability. Key differences include dosage levels, cost implications, and specific applications.

Detailed

Comparison: Chemical vs. Mineral Admixtures

This section delves into the distinctions between chemical and mineral admixtures used in concrete.

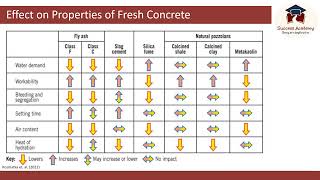

Nature of Admixtures

- Chemical Admixtures: These are typically organic or inorganic solutions designed to enhance the workability, setting time, and overall behavior of fresh and hardened concrete.

- Mineral Admixtures: These are finely divided solids that react chemically during hydration to improve the long-term strength and durability of concrete.

Dosage

- Chemical Admixtures: Generally added in small amounts (less than 5% of the weight of cement).

- Mineral Admixtures: Can range from 5% up to 50% of cement weight.

Timing of Use

- Chemical Admixtures: Employed primarily to control short-term features of concrete, like workability and setting behaviors.

- Mineral Admixtures: Integrate into the concrete mix to strengthen long-term properties and enhance sustainability.

Functionality

- Chemical admixtures focus on adjusting current concrete performance characteristics, while mineral admixtures aim to promote sustainability and durability over the lifespan of the concrete.

Cost Implications

- Chemical admixtures tend to be more expensive than mineral admixtures, which often utilize by-products from other industrial processes, contributing to reduced costs and environmental sustainability.

By understanding these differences, architects and engineers can make informed decisions about the appropriate type of admixture to meet project requirements.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Admixture Nature

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Chemical Admixtures:

- Organic/inorganic chemicals

Mineral Admixtures:

- Finely divided pozzolanic/hydraulic solids

Detailed Explanation

Chemical admixtures can be made from organic or inorganic substances. These are often soluble in water and are added to concrete to alter its properties in the short term. Mineral admixtures are made from very fine materials that can interact chemically with cement to enhance its long-term properties. They are generally solid particles that help improve concrete's durability and strength over time.

Examples & Analogies

Think of chemical admixtures like seasoning in cooking. Just as seasoning can immediately alter the flavor of a dish, chemical admixtures change the properties of concrete right away. On the other hand, mineral admixtures are like slow-cooking vegetables that enhance the base flavor, improving the overall quality of the soup over time.

Dosage Differences

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Chemical Admixtures:

- Dosage < 5% by weight of cement.

Mineral Admixtures:

- Dosage 5–50% by weight of cement.

Detailed Explanation

Chemical admixtures are added in much smaller amounts (less than 5% of the weight of cement). This small dosage is sufficient to effectively influence properties like setting time and workability. Mineral admixtures, in contrast, can be added in larger quantities (from 5% to 50% of the cement weight) because they commonly enhance the mechanical and durability characteristics of the concrete mix over time.

Examples & Analogies

Imagine making a small batch of lemonade. Just a few drops of lemon juice can change the flavor dramatically—that's like chemical admixtures. Now imagine making a large soup; you might need several cups of ingredients to enhance its flavor, similar to how mineral admixtures work in concrete.

Functionality Comparison

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Chemical Admixtures:

- Function: Workability, setting time, air entrainment.

Mineral Admixtures:

- Function: Strength, durability, sustainability.

Detailed Explanation

Chemical admixtures are primarily used to modify fresh concrete characteristics, such as making it easier to mix and pour, managing how quickly it sets, or how much air is trapped within it to improve resistance to freeze-thaw cycles. Mineral admixtures, on the other hand, enhance the long-term qualities of concrete, such as its strength, resistance to deterioration, and overall sustainability by partially replacing cement with materials that are often by-products of industrial processes.

Examples & Analogies

Think of a party where you want to serve drinks (the chemical admixtures) that are easy to mix (workability), change flavors (setting time), or have fizz (air entrainment). For the main dish, however, you want ingredients (the mineral admixtures) like beans or lentils that will boost protein content and make the meal heartier and more sustainable.

Cost Implications

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Chemical Admixtures:

- Cost: Generally higher.

Mineral Admixtures:

- Cost: Lower (by-product reuse).

Detailed Explanation

Chemical admixtures tend to be more expensive because they are specially formulated chemicals that serve specific functions and require careful manufacture. In contrast, mineral admixtures are often less costly since they are by-products of other industrial processes, meaning they can be recycled into new materials for concrete.

Examples & Analogies

Consider buying a gourmet spice blend (the chemical admixtures) that is specially crafted for a unique flavor—it's going to cost more than just buying a bag of beans (the mineral admixtures) that were leftover from another process in food production. Both have their purpose, but the spice will likely cost more for its unique value.

Examples of Each Type

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Chemical Admixtures:

- Examples: Superplasticizer, retarder.

Mineral Admixtures:

- Examples: Fly ash, silica fume.

Detailed Explanation

Common chemical admixtures include superplasticizers, which significantly improve the fluidity of concrete without adding more water, and retarders, which slow down the setting time to allow for longer working periods. Mineral admixtures, such as fly ash and silica fume, are commonly used to augment concrete's strength and durability, especially in large projects or where added performance is required.

Examples & Analogies

Think of a superplasticizer as a secret ingredient that makes your cake batter smoother and easier to pour. Similarly, imagine fly ash as a nutrient-rich additive to soil that enhances plant growth—both enhance performance in their respective areas significantly.

Key Concepts

-

Chemical Admixtures: Modify workability and setting times in concrete.

-

Mineral Admixtures: Enhance long-term durability and sustainability of concrete.

Examples & Applications

A superplasticizer is a type of chemical admixture that improves workability significantly.

Fly ash is a mineral admixture that helps reduce permeability and improve long-term strength.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Admixtures in a mix, keep it slick, Chemical quick, Mineral sticks.

Stories

Once upon a time in a concrete land, chemical admixtures, quick and grand, changed the flow like a stream, while mineral admixtures made structures gleam with long-lasting dreams.

Memory Tools

C for Chemical - changes Concrete fast. M for Mineral - makes it last.

Acronyms

C-M-A

Chemical for Mix

Mineral for Arch.

Flash Cards

Glossary

- Admixtures

Materials added to concrete to improve its properties other than water, aggregates, and cement.

- Chemical Admixtures

Water-soluble materials that modify the behavior of fresh and hardened concrete.

- Mineral Admixtures

Finely divided solids that improve concrete’s long-term properties.

- Pozzolanic

Materials that react with calcium hydroxide to form additional cementitious compounds.

Reference links

Supplementary resources to enhance your learning experience.