Rice Husk Ash (RHA)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Rice Husk Ash

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss Rice Husk Ash, or RHA. Can anyone tell me what RHA is and why it's significant in construction?

Isn't RHA made from burning rice husks?

Exactly! RHA is a by-product of the controlled combustion of rice husks. It's significant because it contains high levels of silica, making it a valuable pozzolanic material. What does 'pozzolanic' mean?

It means it can react with calcium hydroxide to form compounds that improve concrete strength, right?

Correct! This reaction enhances the strength and durability of concrete. Remember, RHA can enhance concrete's chloride resistance too!

Properties and Dosage of RHA

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's dive into the properties of RHA. Why do you think the silica content matters?

Higher silica content means better pozzolanic activity, right?

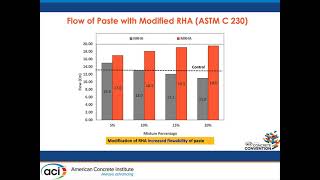

Exactly! A higher silica content enhances the formation of C-S-H gel, improving the microstructure of concrete. Now, what’s the recommended dosage of RHA in concrete mixtures?

I believe it's between 10 to 20 percent of the cement weight.

That's right! Using RHA within this range can optimize the benefits without compromising concrete's performance.

Applications of RHA

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, who can share some applications of RHA in concrete technology?

It's used in sustainable construction because it's environmentally friendly!

Absolutely! RHA helps reduce waste and supports eco-concrete initiatives. Other areas include rural construction. Can anyone explain why RHA is suited for rural infrastructure?

It's likely because it's cost-effective and utilizes local agricultural waste.

Excellent point! Integrating RHA supports the local economy while promoting greener building solutions.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

RHA is a highly pozzolanic material known for its high silica content. It enhances the strength, durability, and chloride resistance in concrete applications, making it suitable for sustainable and eco-friendly construction practices.

Detailed

Rice Husk Ash (RHA)

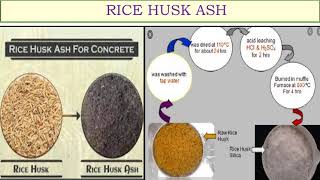

Rice Husk Ash (RHA) is a by-product obtained from the controlled burning of rice husks, which are the outer shell of rice grains. This ash has gained significant attention in the construction industry due to its rich silica content and pozzolanic nature.

Properties: RHA is characterized by its high silica content, making it highly reactive with calcium hydroxide during hydration. This reaction strengthens the concrete matrix, improves durability, and enhances resistance against chloride ingress, thereby prolonging the service life of concrete structures.

Dosage: The recommended usage is between 10–20% of the cement weight.

Applications: RHA serves as a beneficial ingredient in various concrete applications, particularly in sustainable construction, rural infrastructure development, and eco-concrete formulations. By incorporating RHA, concrete can become more environmentally friendly, facilitating waste recycling and lower carbon footprints in the construction sector.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Source of Rice Husk Ash

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Source: Controlled combustion of rice husks.

Detailed Explanation

Rice Husk Ash (RHA) is created through a process called controlled combustion, where rice husks are burned in a specific way to produce ash. This method ensures that the ash retains its beneficial properties for use in concrete. The controlled combustion minimizes the emission of harmful gases and maximizes the amount of silica present in the ash, which is crucial for its pozzolanic activity.

Examples & Analogies

Imagine making a fire to roast marshmallows. If you burn the marshmallows carefully just enough to turn them golden brown without turning them into charcoal, you can enjoy their sweet taste. Likewise, RHA involves burning rice husks just right to extract useful properties for building materials without creating harmful byproducts.

Properties of Rice Husk Ash

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Properties:

- High silica content, highly pozzolanic.

- Enhances strength, durability, and chloride resistance.

Detailed Explanation

RHA has a high silica content, which means it can react chemically with calcium hydroxide produced during concrete hydration, forming compounds that improve the concrete's properties. This pozzolanic activity enhances the overall strength and durability of the concrete while also providing resistance to chloride attacks, which can lead to corrosion in steel reinforcement.

Examples & Analogies

Think of RHA like a superhero for concrete. Just as a superhero boosts the strength of their teammates, RHA boosts the concrete's strength and durability, helping it endure harsh conditions and resist damage, much like a hero protects their city.

Dosage of Rice Husk Ash

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Dosage: 10–20%.

Detailed Explanation

The recommended dosage of Rice Husk Ash in concrete is between 10% to 20% of the total weight of cement. This range is important because using too little may not provide significant improvements, while too much may disturb the balance of concrete properties. It's crucial to ensure that the total cement quantity in the concrete mix remains effective for the intended use.

Examples & Analogies

Adding RHA to concrete is much like adding the right amount of seasoning to a dish. Just a pinch can enhance flavor, but too much can overpower the meal. Similarly, the right dosage of RHA allows concrete to achieve the desired qualities without compromising its structural integrity.

Applications of Rice Husk Ash

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Applications: Sustainable construction, rural construction, eco-concrete.

Detailed Explanation

Rice Husk Ash is primarily used in sustainable and eco-friendly construction projects. Its use not only makes construction more sustainable by utilizing agricultural by-products but also contributes to reducing the carbon footprint associated with traditional cement production. It's particularly beneficial for rural construction, providing a cost-effective and environmentally friendly alternative to conventional materials.

Examples & Analogies

Consider RHA like recycling. Just as recycling paper reduces waste and saves trees, using RHA in construction reduces the need for new cement production, contributing to a healthier planet. Building houses with RHA supports rural communities and helps the environment at the same time.

Key Concepts

-

High Silica Content: RHA is rich in silica, enhancing pozzolanic activity.

-

Chloride Resistance: RHA improves concrete's resistance to chloride ingress.

-

Sustainable Construction: RHA supports eco-friendly building practices.

Examples & Applications

Using RHA in rural development projects to reduce construction costs and utilize local resources.

Incorporating RHA in mass concrete applications to improve long-term strength and sustainability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When rice husks burn, ash is the key, for concrete that’s strong and eco-friendly.

Stories

In a town where rice is grown, the husks, once waste, became RHA known to build homes that stood strong against the storm.

Memory Tools

To remember the benefits of RHA, think of 'SCD': Strength, Chloride resistance, Durability.

Acronyms

RHA - 'Rice Husk Ash' stands for 'Recycled Husk Advantage' in building strength.

Flash Cards

Glossary

- Rice Husk Ash (RHA)

A pozzolanic material produced by the controlled combustion of rice husks, enhancing concrete durability and strength.

- Pozzolanic Reaction

A chemical reaction that occurs between calcium hydroxide and reactive silica in pozzolanic materials, producing additional calcium silicate hydrate.

- Calcium Silicate Hydrate (CSH)

The primary binding compound formed in concrete during the hydration process, contributing to concrete strength.

Reference links

Supplementary resources to enhance your learning experience.