Metakaolin

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Metakaolin

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss metakaolin, a fascinating mineral admixture derived from kaolinite clay. Who can tell me where metakaolin comes from?

Isn't it made from clay that gets heated?

Correct! Metakaolin is created by calcining kaolinite clay at high temperatures. This process enhances its reactivity. Can anyone tell me why this reactivity is important?

It helps improve the strength and durability of concrete, right?

Exactly! The high pozzolanic reactivity of metakaolin leads to better concrete performance. Let's remember that pozzolans like metakaolin react with calcium hydroxide to form additional calcium silicate hydrate, or C-S-H, which is crucial for strength.

Properties and Benefits of Metakaolin

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s dive deeper into the properties of metakaolin. What are some benefits we can associate with this admixture?

It improves early strength and is good for durability!

Absolutely! Enhanced early strength is one of its key advantages. Additionally, metakaolin can help resist alkali-silica reactions—this is vital for preventing damage in concrete over time. Let’s summarize that: it enhances early strength, durability, and mitigates ASR.

What’s the typical dosage used in concrete?

Great question! The typical dosage is between 5% to 15% of the total weight of cement. This range helps achieve optimal performance.

Applications of Metakaolin

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s look at the practical applications of metakaolin. Where do you think it’s most commonly used?

I’ve heard it’s used in white or colored concrete?

Correct! Metakaolin is often used in architectural concrete projects due to its color properties and the improved aesthetics. It’s also used in regions where enhanced durability is crucial. Can anyone think of a construction project that might benefit from metakaolin?

Maybe in bridges or buildings that need to last a long time?

Exactly! Its strength and resistance to ASR make it a top choice for critical structures.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses metakaolin, a mineral admixture known for its high pozzolanic reactivity. It improves early strength, durability, and resistance to alkali-silica reactions in concrete, making it suitable for various applications, including architectural and colored concrete.

Detailed

Detailed Summary of Metakaolin

Metakaolin is a pozzolanic material obtained from the calcination of kaolinite clay. Its high reactivity makes it a valuable mineral admixture in concrete technology. This section highlights its essential attributes:

- Sources: Metakaolin is produced through the heating (calcining) of kaolinite clay at temperatures ranging from 600°C to 800°C, transforming it into its reactive form.

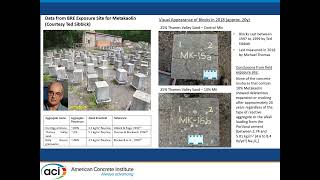

- Properties: It exhibits high pozzolanic reactivity, which significantly enhances early strength and long-term durability of concrete. Moreover, it helps in mitigating the risk of alkali-silica reaction (ASR), which can cause damaging expansion and cracking.

- Dosage: The typical dosage of metakaolin in concrete ranges from 5% to 15% of the total cement weight, leading to optimal improvements in mechanical and durability characteristics.

- Applications: Its unique characteristics make metakaolin an excellent choice for white or colored concrete, architectural projects, and areas where enhanced durability is essential.

By incorporating metakaolin into concrete mixtures, engineers can achieve significant performance improvements, ensuring longevity and structural integrity in their construction projects.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Source of Metakaolin

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Metakaolin

- Source: Calcined kaolinite clay.

Detailed Explanation

Metakaolin is produced by heating kaolinite clay at high temperatures (typically between 650°C and 800°C) which causes a chemical change in the clay structure. This process is known as calcination. The result is a fine, white powder with enhanced properties for use in concrete.

Examples & Analogies

Think of metakaolin like popcorn. Just as popcorn is created by heating corn kernels until they burst, metakaolin is created by heating kaolinite clay until it transforms into a new material with different characteristics. Just like popcorn is light and fluffy, metakaolin is fine and reactive.

Properties of Metakaolin

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Properties:

- High pozzolanic reactivity.

- Improves early strength, durability, and resistance to alkali-silica reaction (ASR).

Detailed Explanation

Metakaolin has a high pozzolanic reactivity, which means it can chemically react with calcium hydroxide (a byproduct of cement hydration) to form additional calcium silicate hydrate (C-S-H). This contributes to the overall strength and durability of concrete. Furthermore, metakaolin helps to enhance the concrete's resistance against alkali-silica reaction (ASR), a detrimental reaction that occurs in concrete when reactive silica from aggregates reacts with the alkali in cement.

Examples & Analogies

Imagine a sponge soaking up water. Just as a sponge can absorb excess water, metakaolin absorbs calcium hydroxide to support the formation of stronger concrete bonds. This way, it helps to keep the concrete strong, just like keeping the water inside a sponge prevents it from becoming too weak and falling apart.

Dosage of Metakaolin

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Dosage: 5–15%.

Detailed Explanation

When integrating metakaolin into concrete, a typical dosage is between 5% to 15% of the weight of cement. This range is effective in enhancing the concrete properties without compromising its performance. Careful consideration must be given to the percentage used, as higher dosages may affect the mix design and properties.

Examples & Analogies

Consider making a smoothie. If you add too much fruit, it can overwhelm the taste and texture. Similarly, using too much metakaolin in concrete can lead to an imbalance in the mix. Using the right amount, just like the right amount of fruit, ensures that the resulting mix has the right properties for strength and durability.

Applications of Metakaolin

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Applications: White/colored concrete, architectural and durable concrete.

Detailed Explanation

Metakaolin is used in many applications including the production of white or colored concrete, where its brightness is an added aesthetic benefit. It's also used in architectural and durable concrete applications due to its strength-enhancing properties and resistance to environmental factors. This makes it ideal for structures that require higher durability and aesthetic appeal.

Examples & Analogies

Think of metakaolin like a secret ingredient in a recipe. Just as a chef might add an ingredient to enhance the flavor and presentation of a dish, builders use metakaolin to enhance both the appearance and strength of concrete structures.

Key Concepts

-

Metakaolin: A pozzolanic material that enhances concrete properties by improving strength and durability.

-

Calcining: The process of converting kaolinite clay into metakaolin by heating.

-

Pozzolanic Reaction: Involves reacting metakaolin with calcium hydroxide to produce more C-S-H in concrete.

-

ASR Mitigation: Metakaolin helps in reducing the adverse effects of alkali-silica reactions.

Examples & Applications

Metakaolin is often used in the production of high-performance concrete for bridges, enhancing both aesthetic qualities and structural integrity.

In architectural applications, metakaolin can be used to create colored concrete without compromising on durability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Metakaolin's the name, and strength is its game, in concrete it finds fame!

Stories

Once upon a time, there was a special clay that, when heated, transformed into metakaolin. This clay became a hero, enhancing the strength and beauty of concrete structures everywhere.

Memory Tools

To remember the benefits of metakaolin—Strength, Durability, ASR Mitigation—just think 'SDA' for Super Durable Admixture!

Acronyms

MAST

Metakaolin Adds Strength and Toughness.

Flash Cards

Glossary

- Metakaolin

A pozzolanic material derived from the calcination of kaolinite clay, known for enhancing concrete properties.

- Calcination

The process of heating a substance to a high temperature but below its melting point to bring about thermal decomposition.

- Pozzolanic Reaction

A chemical reaction in which pozzolans react with calcium hydroxide and water to form additional calcium silicate hydrate.

- Calcium Silicate Hydrate (CSH)

The primary binding phase in concrete, formed through the hydration of cement.

- AlkaliSilica Reaction (ASR)

A reaction between alkali in cement and reactive silica in aggregates, leading to expansion and cracking in concrete.

Reference links

Supplementary resources to enhance your learning experience.