Ground Granulated Blast Furnace Slag (GGBS)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to GGBS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will discuss Ground Granulated Blast Furnace Slag, or GGBS. GGBS is a by-product from the iron-making process in blast furnaces. Can anyone tell me why GGBS might be important in concrete?

It might help improve the properties of concrete!

Exactly! GGBS enhances workability and long-term durability. It’s crucial for making concrete more resistant to environmental factors.

So, it’s like adding vitamins to concrete?

That's a creative way to put it! Just as vitamins boost our health, GGBS boosts concrete’s structural integrity.

Benefits of GGBS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s dive deeper into the benefits of using GGBS. What do you think improves when we use GGBS in concrete?

I think it helps with the strength and durability of concrete.

Correct! It not only increases long-term strength but also reduces permeability, making concrete more durable in harsh conditions. Anyone know how it affects heat of hydration?

Does it decrease the heat generated during curing?

Spot on! Lower heat generation is crucial for preventing thermal cracking in large pours. Let’s remember this with the acronym WHDS — Workability, Heat, Durability, Strength.

Applications of GGBS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s talk about the applications of GGBS. In which types of projects do you think GGBS is most beneficial?

I guess it would be useful in marine structures.

Absolutely! GGBS is particularly beneficial in marine applications and sewage treatment plants due to its sulfate resistance. It’s also great for mass concrete applications. Can anyone tell me why its sulfate resistance is advantageous?

It prevents damage from sulfates in water, right?

Correct! GGBS helps in preserving the concrete over time, especially in critical environments. Remember, using GGBS is not just about enhancing strength; it's about sustainability too.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

GGBS, a by-product from iron production, is utilized in concrete to improve workability, lower heat of hydration, enhance sulfate resistance, and provide longer-term durability. Its typical dosage ranges from 30% to 50% of the cement weight and is especially useful in marine works and mass concrete applications.

Detailed

Ground Granulated Blast Furnace Slag (GGBS)

Ground Granulated Blast Furnace Slag (GGBS) is a by-product derived from the iron-making process in blast furnaces. Being a latent hydraulic material, GGBS is recognized for its ability to react with calcium hydroxide (Ca(OH)₂) released during cement hydration, forming additional calcium silicate hydrate (C-S-H) gel. This gel positively impacts concrete properties in several ways:

- Workability: GGBS improves the workability of concrete mixes, which is crucial for achieving a homogenous mix.

- Long-term Durability: It enhances durability over time, making concrete resistant to various environmental factors.

- Reduced Heat of Hydration: GGBS lowers the heat generated during cement hydration, making it ideal for massive pours and conditions where thermal cracking is a concern.

- Enhanced Sulfate Resistance: The use of GGBS provides significant resistance against sulfate attacks, extending the lifespan of concrete structures.

Common dosage levels of GGBS in concrete range from 30% to 50% of the weight of cement. It finds extensive applications in demanding environments like marine construction and sewage treatment plants, as well as mass concrete applications due to its attributes. This material not only provides structural support but also contributes to sustainable construction practices by utilizing industrial by-products.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Source of GGBS

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

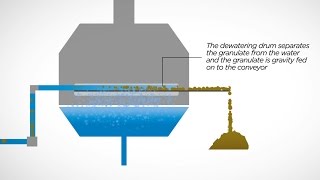

• Source: By-product of iron production in blast furnaces.

Detailed Explanation

Ground Granulated Blast Furnace Slag (GGBS) is a by-product generated during the process of iron manufacturing in blast furnaces. During this process, molten iron is produced alongside slag, which is then rapidly cooled and ground to a fine powder to create GGBS. This makes it an industrial by-product that can be reused in concrete, contributing to sustainability.

Examples & Analogies

Imagine making a large steak dinner where, along with eating the steak, you also have gravy left over that can be used in future meals. Just like you wouldn't want to waste that delicious gravy, GGBS helps prevent waste by reusing by-products from iron production.

Properties of GGBS

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Properties:

o Latent hydraulic material.

o Improves workability and long-term durability.

o Lowers heat of hydration and enhances sulfate resistance.

Detailed Explanation

GGBS possesses unique properties that enhance the performance of concrete. As a latent hydraulic material, it reacts with calcium hydroxide formed during cement hydration, contributing to additional strength. It improves workability, making the concrete easier to mix and handle. Additionally, GGBS lowers the heat generated during hydration, which is particularly beneficial in large scale pours, and it also improves resistance to sulfates, which can damage concrete over time.

Examples & Analogies

Think of GGBS like a secret ingredient in a recipe that enhances the dish. Just like how adding a little bit of garlic can elevate a pasta dish, adding GGBS makes concrete stronger and more workable.

Dosage of GGBS

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Dosage: 30–50%.

Detailed Explanation

The recommended dosage of GGBS in concrete mixes ranges from 30% to 50% of the cement weight. This means that if you are using 100 kg of cement in your concrete, you can replace 30 to 50 kg of it with GGBS. This substitution not only contributes to the sustainability of the construction process but can also enhance the overall performance of the concrete.

Examples & Analogies

Consider baking a cake. If the recipe calls for two cups of flour, you might replace half a cup with almond flour for added flavor and nutrition. Similarly, using 30-50% GGBS instead of regular cement can enhance the properties and sustainability of the concrete.

Applications of GGBS

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Applications: Marine works, sewage treatment plants, mass concrete.

Detailed Explanation

GGBS is utilized in various applications due to its enhanced properties. It is especially valuable in marine works where resistance to chlorides and sulfates is critical, such as in piers and docks. Additionally, its durability makes it suitable for sewage treatment plants, where the environment can be aggressive to concrete materials. Furthermore, GGBS is commonly used in mass concrete applications to manage heat generation and improve long-term strength.

Examples & Analogies

Think of GGBS as the tough, reliable materials used in building a bridge. Just as a bridge needs to endure the harsh conditions of vehicles and weather, structures built with GGBS can withstand tough environments, like those found in marine or sewage applications.

Key Concepts

-

GGBS: A supplementary material improving concrete's properties.

-

Workability: GGBS enhances the ease of mixing and placing concrete.

-

Durability: It improves the long-term resistance of concrete against environmental factors.

-

Heat of Hydration: GGBS helps lower the heat generated during hydration.

-

Sulfate Resistance: It prevents damage from sulfates, making concrete last longer in harsh environments.

Examples & Applications

GGBS is applied in the construction of bridges, roads, and marine structures due to its durability.

Mass concrete pours for foundations benefit from GGBS by reducing thermal cracking.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

GGBS makes concrete strong and last, lower heat and sulfate attacks are surpassed.

Stories

Imagine a bridge growing stronger with every rain; that's GGBS, fighting sulfate pain.

Memory Tools

Remember WHDS: Workability, Heat, Durability, Strength for GGBS benefits.

Acronyms

GGBS

Ground Granulated Benefits Strength.

Flash Cards

Glossary

- GGBS

Ground Granulated Blast Furnace Slag, a by-product from iron production that enhances concrete properties.

- Latent Hydraulic Material

A substance that can react with water and calcium hydroxide to improve concrete's properties.

- CSH Gel

Calcium Silicate Hydrate gel that forms during cement hydration and contributes to the strength of concrete.

- Sulfate Resistance

The ability of concrete to withstand deterioration due to exposure to sulfate ions.

- Permeability

The ability of a material to allow fluids to pass through it.

Reference links

Supplementary resources to enhance your learning experience.