Shrinkage-Reducing Admixtures

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Shrinkage-Reducing Admixtures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are discussing Shrinkage-Reducing Admixtures, often abbreviated as SRAs. Can anyone tell me what you think might be the primary function of these admixtures?

Do they reduce the amount of shrinkage in concrete?

Exactly! SRAs are specifically designed to minimize drying shrinkage and reduce the likelihood of cracking. They achieve this by lowering the surface tension of the water in the pores of the concrete. Why do you think decreasing surface tension is important?

I guess it helps the water not pull together as much and potentially cause cracks?

That's a great insight! Ultimately, this reduces capillary stress and helps keep our concrete structures intact. Let's remember this with the acronym 'SRA' – Shrinkage Reduction Aid. Now, can anyone think of where we might want to use these admixtures?

Like in bridge decks or maybe large industrial floors?

Spot on! Bridge decks and industrial floors are indeed common applications for SRAs. They help enhance durability where conditions can lead to significant drying.

Mechanism of Action of SRAs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive deeper into how SRAs work. They primarily reduce the surface tension of the water present in the concrete. Can someone explain, in simpler terms, what surface tension means?

Isn't it like how water molecules stick together on a surface? Like when droplets form?

Absolutely! Now, by reducing that surface tension, the water can permeate the mixture differently, reducing the chance of cracking as it dries. Can anyone think of the implications if we don’t use SRAs in concrete mixes?

More cracks would appear, which isn’t good for long-term durability!

Exactly! Long-term performance can significantly diminish without SRAs. So, as you can see, they really are crucial additives for concrete used in critical environments.

Applications of SRAs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we’ve covered how SRAs work, let’s look at their applications. What types of projects do you think could benefit from using these admixtures?

Maybe repair works or places that are exposed to water?

Exactly, repair works are key! Places like bridge decks, industrial floors, and structures susceptible to temperature changes are integral as well. Using SRAs in these applications helps prevent damage that can arise due to shrinkage. Why do you think it's especially critical in bridge decks?

Because they deal with heavy loads and environmental stress?

Yes! Loads and stresses from weather can exacerbate issues such as cracking. Now, does anyone recall an example of an SRA we mentioned earlier?

Polypropylene glycol derivatives?

Exactly right! Remember, using SRAs is a step toward ensuring longevity and durability in our concrete work.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

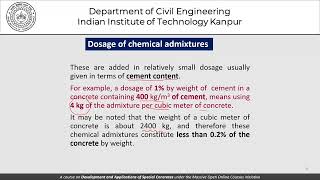

Shrinkage-Reducing Admixtures (SRAs) are chemical additives that reduce the drying shrinkage of concrete, helping to prevent cracks and improve durability. They work by lowering the surface tension of water in the concrete, significantly enhancing its performance in various applications such as bridge decks and industrial floors.

Detailed

Detailed Summary

Shrinkage-Reducing Admixtures (SRAs) play a crucial role in minimizing drying shrinkage in concrete, a common concern that often leads to cracking and durability issues. By including these admixtures, the surface tension of water in the concrete pores is reduced, which decreases capillary stress during the drying process. A notable example of SRAs includes polypropylene glycol derivatives, which have been successfully utilized in applications like bridge decks and industrial flooring systems. By reducing the tendency for cracks, SRAs enhance the long-term performance and integrity of concrete structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Purpose of Shrinkage-Reducing Admixtures

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Minimize drying shrinkage and cracking.

Detailed Explanation

Shrinkage-reducing admixtures are used in concrete mixes primarily to decrease the amount of shrinkage that occurs as the concrete dries. Drying shrinkage is a common issue where the concrete reduces in volume as moisture evaporates. This can lead to cracking and other structural issues. By introducing specific chemical components, these admixtures work to control the moisture loss and its subsequent impact on the concrete's integrity.

Examples & Analogies

Imagine a balloon that slowly loses air. As the air escapes, the balloon shrinks, and if you pull it too tight, it may pop. Similarly, as concrete loses moisture, it shrinks, which can create cracks if not managed. Shrinkage-reducing admixtures act like a gentle hand on the balloon, reducing the pressure and preventing it from bursting.

Mechanism of Action

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Reduce surface tension of water in pores, decreasing capillary stress.

Detailed Explanation

The mechanism by which shrinkage-reducing admixtures work involves reducing the surface tension of the water present in the pores of the concrete. When surface tension is high, water tends to form droplets rather than spreading evenly. This uneven distribution creates capillary stress - a pressure that can amplify shrinkage. By reducing the surface tension, these admixtures allow water to spread more evenly, relieving internal stress and minimizing the potential for cracking as the concrete dries.

Examples & Analogies

Consider a sandy beach where water seeps into the sand. If the sand is too dry, the water forms little pools that don't spread out much, creating weak spots. But if a detergent (similar to the admixture) is added to the water, it spreads across the sand evenly, reducing the dry spots and making the sand more stable. In concrete, lower surface tension means a more uniform drying process, which helps prevent cracks.

Examples of Shrinkage-Reducing Admixtures

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Polypropylene glycol derivatives.

Detailed Explanation

One common example of a shrinkage-reducing admixture is polypropylene glycol derivatives. These are organic compounds that help to achieve the shrinkage reduction by improving the performance of water within the concrete matrix. The choice of specific admixture can vary depending on the project's requirements, including the desired degree of shrinkage control and the exposure conditions of the concrete.

Examples & Analogies

Think about using a special type of lotion on your skin. Some lotions hydrate better than others, keeping your skin from drying out and cracking. Similarly, polypropylene glycol derivatives help keep the concrete's moisture in balance, preventing it from drying out too quickly and forming cracks.

Applications of Shrinkage-Reducing Admixtures

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bridge decks, industrial floors, repair works.

Detailed Explanation

Shrinkage-reducing admixtures are particularly beneficial in applications where minimizing shrinkage is crucial. For example, in bridge decks, which are subjected to environmental fluctuations, the use of these admixtures can help prolong the lifespan and structural integrity of the deck by preventing cracks. Similarly, in industrial floors that need to withstand heavy loads and movement, reducing shrinkage is important to maintain smooth surfaces and prevent unevenness. In repair works, these admixtures ensure that new concrete adheres properly and behaves predictably with existing structures.

Examples & Analogies

Consider the importance of keeping a road smooth and crack-free to ensure safe driving. By using shrinkage-reducing admixtures in the concrete used for bridge decks, we ensure that the 'road' stays even and safe, just as a well-maintained surface in your home keeps you from tripping over cracks.

Key Concepts

-

Shrinkage-Reducing Admixtures: Chemicals that reduce drying shrinkage in concrete.

-

Surface Tension: A force that can lead to cracking if not controlled.

-

Capillary Stress: A stress due to liquid in small spaces affecting concrete integrity.

Examples & Applications

Using SRAs in bridge decks to mitigate cracking due to environmental changes.

Incorporating SRAs in industrial flooring to enhance durability under heavy loads.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When concrete dries and cracks abound, help is here, SRAs are found!

Stories

Imagine building a bridge; you add a magical potion, SRAs, which keep the bridge strong and avoid cracks even in tough conditions.

Memory Tools

Remember SRAs as 'Surface tension reducers for Avoiding cracks!'

Acronyms

SRA - Shrinkage Reduction Aid.

Flash Cards

Glossary

- ShrinkageReducing Admixtures

Admixtures designed to minimize drying shrinkage and cracking in concrete.

- Surface Tension

The cohesive force that causes water molecules to stick together at the surface of the water.

- Polypropylene Glycol Derivatives

A type of SRA that helps reduce surface tension in concrete mixes.

- Capillary Stress

The stress that occurs due to the force of liquid in tiny spaces, affecting the drying and cracking of concrete.

Reference links

Supplementary resources to enhance your learning experience.