Sustainability and Environmental Impact

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Role of Mineral Admixtures in Green Construction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will explore the role of mineral admixtures in sustainable construction. Can anyone name a few mineral admixtures?

Isn't fly ash one of them?

Exactly! Fly ash and GGBS are crucial in reducing the amount of cement needed in concrete. This lowers CO₂ emissions significantly. Remember, each ton of cement replaced helps avoid nearly 0.9 tons of CO₂ emissions. We can think of this impact as 'One Ton Saved' for every ton of ash used!

That’s a great point! Are there other benefits apart from just reducing emissions?

Good question! Using these materials also promotes the circular economy by utilizing waste products from industry. This way, we are not just reducing emissions, but also making smart use of materials.

So, it’s environmentally beneficial and economical at the same time?

Absolutely. It’s a win-win! Remember that the more we use these by-products, the better we contribute to sustainability.

What about the percentages used in concrete mixes? Is there a standard?

Yes, typically, fly ash is used at about 15 to 35% of cement weight. Each mix can differ depending on specific project needs.

Concrete Emissions Reduction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive deeper into how high-volume fly ash concrete can help in reducing emissions. Who can provide me with the potential reductions in emissions?

I heard it can reduce emissions by up to 40%!

Correct! By replacing a significant part of cement with fly ash, HVFAC helps in dramatically reducing the carbon footprint. It encourages us to think of concrete as a sustainable service rather than just a construction material.

Does this HVFAC have the same strength as regular concrete?

Great question! While it can achieve comparable strength, proper mix design and application are essential. This underscores our need to understand both the chemistry and the engineering aspects of concrete mixtures.

What about the process to use in green certification for buildings?

Excellent point! Using certified SCMs not only enhances a concrete's ecological profile but also contributes points in certification systems like LEED and GRIHA. It signifies sustainability commitment in construction.

So by making choices about our materials, we can make a real difference?

Exactly! Every decision counts in the move towards a greener environment in the construction industry.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section elaborates on how mineral admixtures like fly ash, GGBS, and silica fume contribute to sustainable construction by reducing cement consumption, which in turn lowers CO₂ emissions. It also discusses the potential for high-volume fly ash concrete and its contributions to green building rating systems like LEED and GRIHA.

Detailed

Sustainability and Environmental Impact in Concrete Construction

In recent years, the emphasis on sustainable construction practices has grown significantly, and the incorporation of mineral admixtures plays a crucial role in achieving these goals. Mineral admixtures, such as fly ash, ground granulated blast furnace slag (GGBS), and silica fume, are increasingly recognized for their ability to reduce the quantity of cement needed in concrete production. This reduction not only diminishes the embodied carbon associated with cement manufacturing but also promotes the principles of a circular economy by utilizing industrial by-products.

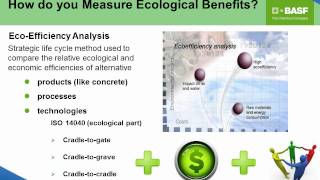

Key Contributions to Carbon Footprint Reduction

The environmental benefits of using mineral admixtures are pronounced. For every ton of cement replaced with fly ash or GGBS, approximately 0.9 tons of CO₂ emissions are avoided. Notably, high-volume fly ash concrete (HVFAC) can lead to a remarkable decrease in emissions by up to 40% when compared to ordinary Portland cement (OPC) concrete. This reduction helps mitigate the impact of the construction industry on climate change, aligning with global sustainability goals.

LEED and GRIHA Ratings

Mineral admixtures also enhance the sustainability profiles of concrete mixes, contributing points to green building rating systems such as LEED (Leadership in Energy and Environmental Design) and GRIHA (Green Rating for Integrated Habitat Assessment). Utilizing certified supplementary cementitious materials (SCMs) is favored in sustainable infrastructure projects for lowering the embodied energy of construction materials. As a result, the concrete industry moves toward cleaner and more sustainable practices that not only benefit the environment but also result in more durable and long-lasting structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Role of Mineral Admixtures in Green Construction

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fly ash, GGBS, and silica fume help reduce cement usage, thereby reducing CO₂ emissions.

Incorporation of waste by-products promotes circular economy principles.

Detailed Explanation

This chunk highlights the important role of mineral admixtures like fly ash, Ground Granulated Blast Furnace Slag (GGBS), and silica fume in promoting sustainability in construction. By using these materials, the overall amount of cement required can be reduced, which directly lowers carbon dioxide (CO₂) emissions since cement production is a major source of these emissions. Additionally, utilizing by-products from other industries contributes to a circular economy, where waste materials are reused, thus decreasing environmental impact.

Examples & Analogies

Think of it like recycling in your home: when you recycle paper or plastic, you help reduce the amount of waste in landfills and conserve resources used to make new products. Similarly, using fly ash or GGBS in concrete is like 'recycling' industrial waste into valuable construction materials, which helps the environment.

Carbon Footprint Reduction

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Each ton of cement replaced by fly ash or GGBS avoids ~0.9 tons of CO₂ emissions.

High-volume fly ash concrete (HVFAC) can cut emissions by up to 40% compared to OPC concrete.

Detailed Explanation

This chunk emphasizes the significant impact that substituting even small amounts of conventional Portland cement (OPC) with fly ash or GGBS can have on reducing carbon emissions. For every ton of cement that is replaced, it is estimated that about 0.9 tons of CO₂ emissions are prevented. Furthermore, in cases where a high volume of fly ash is used, the total carbon emissions can be reduced by as much as 40%. This means that using these mineral admixtures not only makes concrete more sustainable but also plays a crucial role in combating climate change.

Examples & Analogies

Imagine if you could reduce your car's emissions significantly just by changing the type of fuel you use. That's essentially what substituting cement with fly ash or GGBS does for concrete – it’s a change that produces profound environmental benefits, much like choosing to drive a hybrid car instead of a traditional gasoline one.

LEED and GRIHA Ratings

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Use of certified SCMs contributes points in green building rating systems.

Lower embodied energy materials are preferred in sustainable infrastructure.

Detailed Explanation

In this part, the focus is on the certification of Supplementary Cementitious Materials (SCMs) like fly ash and GGBS. When these materials are used in construction, they can help projects earn points in green building certifications such as LEED (Leadership in Energy and Environmental Design) and GRIHA (Green Rating for Integrated Habitat Assessment). These certifications recognize sustainable practices and materials that reduce a building's overall energy consumption or environmental impact. The emphasis is on using materials with low embodied energy, which refers to the total energy required to extract, process, and transport a material.

Examples & Analogies

Consider these ratings like earning stars or badges in a video game. Just as you collect achievements for completing levels or missions, green projects gain recognition for using environmentally friendly practices and materials. The greater the number of green materials used, the more points—and 'stars'—the project can earn, making it a 'hero' in sustainability.

Key Concepts

-

Mineral Admixtures: These replace part of cement in mixes, lowering environmental impact.

-

CO₂ Emissions Reduction: Each ton of concrete replaced with fly ash can minimize emissions by 0.9 tons CO₂.

-

Sustainable Construction: Emphasizes using recycled materials and reducing waste.

-

Circular Economy: Promotes reusing materials and minimizing environmental harm.

-

Green Certification: Certifications like LEED and GRIHA promote sustainable building practices.

Examples & Applications

Replacing 30% of Portland cement with fly ash in a concrete mix can significantly lower CO₂ emissions.

Using GGBS in marine structures increases durability and reduce environmental impact by 50%.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Fly ash replaces cement, save the earth, that's the intent.

Stories

Imagine building a strong house, but instead of using just cement, you mix in flying ash like magic dust, making it even stronger and kinder to the planet.

Memory Tools

FLY - Fly ash lowers CO₂ and yields sustainable construction.

Acronyms

SAVE

Sustainability Achieved via Mineral Admixtures for the Environment.

Flash Cards

Glossary

- Mineral Admixtures

Finely divided materials added to concrete to enhance its properties and reduce the need for cement.

- Sustainability

Development that meets present needs without compromising the ability of future generations to meet theirs.

- CO₂ Emissions

Carbon dioxide emissions resulting primarily from burning fossil fuels and cement production.

- HighVolume Fly Ash Concrete (HVFAC)

Concrete that replaces a significant portion of cement with fly ash, reducing environmental impact.

- Circular Economy

An economic system aimed at eliminating waste and the continual usage of resources.

- LEED

Leadership in Energy and Environmental Design; a green building certification program.

- GRIHA

Green Rating for Integrated Habitat Assessment; a national rating system for green buildings in India.

Reference links

Supplementary resources to enhance your learning experience.