Compaction

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into the concept of compaction and why it's crucial for subgrade soils in pavements. Can anyone tell me what compaction means?

Is it about making the soil denser?

Exactly! Compaction is the process of increasing soil density by reducing air voids. What do you think happens if soil isn't compacted properly?

It might not support the pavement well, right?

Correct! Proper compaction enhances load-bearing capacity and minimizes risks of pavement distress. One fun fact: think of compaction as giving the soil a firm handshake – it helps bond layers together!

Can you explain how moisture content affects compaction?

Good question! Moisture content significantly influences compaction. There's an optimum moisture content (OMC) that allows the soil particles to move more easily together, reaching maximum density. Remember: 'Compaction needs water to be smarter!'

What about different methods of compaction?

Great point! Common methods include vibratory, static, and impact compaction, each suited to different soil types and project needs. Let's summarize: Compaction increases soil strength by decreasing air gaps and it's vital for preventing future pavement issues.

Methods of Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's explore methods of compaction. Who can name some common methods?

Vibratory compaction?

Correct! Vibratory compaction uses vibrations to help soil particles settle. Can anyone think of an advantage of this method?

It works well for granular soils?

Yes! It's highly effective with sands and gravels. What about static compaction?

That would use a heavy weight to compress the soil, right?

Exactly! Static compaction is great for cohesive soils. Think of it this way: 'Weight equals strength!' Always ensure you're using the right method for your soil type.

How do we know if the compaction is effective?

Excellent question! We perform density tests, like the sand cone method, to measure the effectiveness of compaction. Remember, the right method and moisture content leads to a robust pavement structure!

So, the key takeaway is to tailor our approach based on soil types?

Exactly! Every soil is unique, and we must adapt our compaction strategies accordingly. We'll continue with more details on how these methods vary next.

Impact of Compaction on Soil Strength

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Alright, class, let's discuss how compaction directly impacts soil strength. Can anyone explain why we care about the strength of subgrade?

It affects the durability of the pavement!

Exactly! Stronger subgrade leads to better load distribution and less pavement distress. Think of soil strength as the foundation of our roadway. What factors do you think influence this strength?

Moisture content is one, right?

Correct! Higher moisture can weaken soil structure. Remember: 'Moist soil is a weak ally!' We also consider soil types—clayey soils require different approaches compared to sandy soils.

So, compaction makes soils stiffer and more supportive?

Right again! Think of it this way: greater density from compaction means less settlement and longer-lasting pavements. Always keep in mind: 'Dense soil, stable road!'

And using the correct compaction technique also matters?

Absolutely! It's all about striking the right balance among soil type, moisture, and compaction technique to achieve optimum results. For our next summary, let’s review the main concepts we've discussed!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Compaction improves the dry density and strength of subgrade soils, making it a fundamental technique in pavement engineering. Key factors include moisture content and the compaction method used, which significantly influence soil performance under loading.

Detailed

Compaction

Compaction is a vital process in pavement engineering aimed at increasing the strength of subgrade soils. It involves mechanically increasing the soil's density by expelling air and reorganizing soil particles. The effectiveness of compaction is primarily influenced by moisture content; soils compacted at their optimum moisture content (OMC) achieve maximum density and strength. Common methods include static, vibratory, and impact compaction. Adequate compaction contributes to the durability, load-bearing capacity, and overall performance of pavement surfaces, reducing potential for future distress such as cracking or rutting. As such, understanding and implementing effective compaction techniques is essential in achieving a robust subgrade layer that extends the service life of pavements.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Compaction

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Most common and cost-effective method.

Detailed Explanation

Compaction refers to the process of increasing the density of soil by reducing the volume of air between soil particles. This process is crucial for ensuring that the soil can bear loads effectively. It is the most widely applied method because it is efficient in improving soil strength at a lower cost compared to other methods.

Examples & Analogies

Imagine trying to pack a suitcase for a trip. If you just throw clothes in haphazardly, it won't zip up. However, if you compress and organize the clothes, you'll make the most out of the space, allowing you to fit more items securely. Similarly, compaction packs the soil particles tighter together, increasing their load-bearing capacity.

Objectives of Compaction

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Increase soil density to improve load-bearing capacity.

- Reduce settlement of pavement over time due to traffic loads.

Detailed Explanation

The primary objective of compaction is to increase the density of soil. This increased density enhances the soil's ability to support loads from pavements and structures, which is particularly important under heavy traffic. Additionally, proper compaction reduces the likelihood of settlement, or sinking, of the pavement as it ages.

Examples & Analogies

Consider a sponge that is full of air. If you press on it, it squeezes down, becoming denser and able to hold more water. Similarly, when soil is compacted, it becomes denser and better suited to support the weight of vehicles and infrastructure above.

Factors Affecting Compaction

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Compaction is influenced by:

- Moisture content.

- Soil type.

- Compaction effort applied.

Detailed Explanation

Several factors affect the effectiveness of compaction. Moisture content is important; too much or too little water can hinder the process. Different types of soil have varying responses to compaction—some may compact easily (like sand), while others (like clay) may require more effort. The amount of effort or force used in the compaction process also significantly influences the final density achieved.

Examples & Analogies

Think about making dough. If you're trying to knead it together but don't add enough water, it remains dry and crumbly. Conversely, if you add too much water, it becomes sticky and hard to shape. Similarly, achieving the right balance of moisture content is essential when compaction is performed on soil.

Compaction Techniques

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

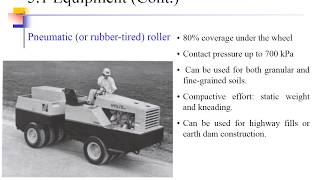

Techniques include:

- Vibratory rollers for granular soils.

- Static rollers for cohesive soils.

- Manual compactors for small areas.

Detailed Explanation

Different techniques are employed depending on the type of soil and the area needing compaction. Vibratory rollers use vibrations to penetrate and compact granular soils effectively. Static rollers apply steady pressure, useful for cohesive soils like clay. For small areas or spots requiring repair, manual compactors are often used.

Examples & Analogies

Imagine you are trying to flatten out a patch of grass. If it’s a large area, you might use a heavy roller (like a vibratory roller) to even it out quickly. For small patches, you’d likely use your hands or a smaller tool (similar to a manual compactor) to get it just right. This analogy illustrates selecting the right tool for the size and type of job at hand.

Monitoring Compaction

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Ensure adequate density is achieved through testing methods.

- Field density testing methods include sand cone and nuclear density gauge.

Detailed Explanation

To verify that effective compaction has been achieved, monitoring and testing are essential. Field density tests, such as using a sand cone or a nuclear density gauge, are employed to ensure that the soil has reached the required density for the desired load-bearing capacity.

Examples & Analogies

When baking bread, you often check if it's done by inserting a toothpick. If it comes out clean, you know it's ready; if not, you put it back in. Similarly, testing soil compaction is essential to confirm it's ready to support whatever will be built on top of it, like a new road or building.

Key Concepts

-

Compaction: Key for increasing soil strength and density.

-

Optimum Moisture Content: The ideal water level for maximum compaction efficiency.

-

Vibratory and Static Compaction: Different methods suited to various soil types.

Examples & Applications

In construction, a vibratory roller is used to compact granular soils like sand for roadways, ensuring a stable surface.

In clayey soil areas, static compaction might be applied to avoid water logging during the process, enhancing strength.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To compact soil, don't be shy, Add some water, give it a try!

Stories

Once a builder named Sam learned that moisture helps his soil become grand. With compaction done just right, pavements stood firm, day and night.

Memory Tools

D-R-E-A-M: Density, Reduce air voids, Ensure moisture, Achieve maximum strength.

Acronyms

C-O-R-E

Compaction Optimizes Roadway Efficiency.

Flash Cards

Glossary

- Compaction

The process of increasing soil density by reducing air voids through mechanical means.

- Optimum Moisture Content (OMC)

The moisture content at which a soil can achieve its maximum density when compacted.

- Vibratory Compaction

A method of compaction that employs vibrations to aid in the densification of soil.

- Static Compaction

A compaction method that uses weight to compress soil without vibration.

Reference links

Supplementary resources to enhance your learning experience.