Direct Shear Test

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Direct Shear Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we'll discuss the Direct Shear Test, which is fundamental in assessing the shear strength of soils. Can anyone explain why determining the shear strength is important for pavements?

I think it helps us know how well the soil can support the pavement, right?

Exactly! The shear strength helps predict how soil will behave under traffic loads. Now, let's go over what the test involves. Essentially, we shear a soil sample under a controlled normal load. Does anyone know what we aim to measure during this test?

We measure the cohesion and internal friction angle of the soil, correct?

That's right! These parameters, cohesion (c) and the internal friction angle (φ), are crucial for understanding soil stability. Let's remember them with the acronym 'CIF'—Cohesion, Internal friction, and Failure parameters. We'll see how they form a failure envelope.

Procedure of the Direct Shear Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's delve into the procedure of the Direct Shear Test. Who can describe the initial steps of conducting this test?

We start by preparing a cylindrical soil specimen, right?

Correct! The soil specimen is placed in a shear box. We then apply normal stress before beginning the shear process. What do you think happens once we start applying shear load?

The soil will start to fail eventually as we apply more shear force?

Yes! We monitor the shear force and record the maximum value attained. This gives us vital data to plot our failure envelope. Remember, success in this test relies on precision—so we always follow protocols meticulously.

Data Interpretation from Direct Shear Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

After conducting the test, we have a crucial step—interpreting the data. Can anyone explain what we do with the shear and normal stresses?

We graph the normal stress against the shear stress to create the failure envelope!

Absolutely right! The slope of this graph defines the internal friction angle, while the intercept gives us the cohesion. This forms our critical parameters for design. Let's use the mnemonic 'FC'—'Failure and Cohesion'—to remind us what we're looking for.

Got it! This data seems really useful for predicting how the soil interacts with loads!

Exactly! Each soil sample reveals its unique behavior, making this test vital in engineering applications.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

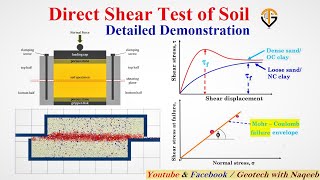

This section discusses the Direct Shear Test, which involves shearing a soil specimen along a predefined plane under a normal load. The test measures key shear strength parameters, including cohesion (c) and internal friction angle (φ), which are critical for understanding soil behavior in engineering applications.

Detailed

Direct Shear Test

The Direct Shear Test is crucial in determining the shear strength parameters of soils, specifically its cohesion (c) and internal friction angle (φ). This test is particularly significant in the context of pavement design, where accurate knowledge of soil strength is essential to predict performance under load.

The test involves applying a normal load to a soil sample which is then sheared along a predefined plane. The shear force is systematically increased, allowing for the collection of data that describes the failure envelope. This envelope serves as a graphical representation of the soil's shear strength properties. The insights gained from this intuitive and tactile test are fundamental for evaluating soil stability and designing pavement systems effectively.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Direct Shear Test Procedure

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

4.3.2.3 (c) Direct Shear Test

- Procedure: Soil sample is sheared along a predefined plane under a normal load.

Detailed Explanation

The Direct Shear Test involves taking a sample of soil and placing it in a device that allows it to be sheared. This is done by applying a normal load on the soil sample, creating pressure from above. The device has a predefined plane along which the soil sample will fail under shear stress. The test then gradually applies horizontal shear force until the soil fails. The response of the soil is monitored, allowing the determination of the soil's shear strength.

Examples & Analogies

Imagine trying to push a book across a table. If you push too hard, it will slide off the edge. The Direct Shear Test is similar; it measures how much force you need to apply to make the soil slide or fail along a given plane.

Strength Parameters Obtained

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Strength Parameters: c and φ obtained from failure envelope.

Detailed Explanation

In the Direct Shear Test, the results provide two key parameters of soil strength: cohesion (c) and the internal friction angle (φ). The failure envelope is a graphical representation of how the soil behaves under varying levels of stress. The cohesion value indicates the inherent strength of the soil when no external forces are acting upon it, while the internal friction angle represents the resistance the soil provides against sliding when forces are applied. Analyzing this envelope helps engineers understand how the soil will behave under load.

Examples & Analogies

Think of a stack of playing cards. The cohesion (c) is like how sticky the cards are to each other when you try to pull one out, while the internal friction angle (φ) would represent the angle at which the stack tips over when you push on the top. Both measurements help you predict how stable the stack will be.

Key Concepts

-

Direct Shear Test: A method to determine the shear strength parameters of soil by applying shear forces under controlled conditions.

-

Cohesion (c): Represents the soil’s ability to stick together under load.

-

Internal Friction Angle (φ): A measure of how much resistance soil offers to shear forces based on particle interactions.

-

Failure Envelope: A graphical representation of the relationship between normal and shear stress at failure.

Examples & Applications

An engineer performs a Direct Shear Test on a clay soil sample to determine its bearing capacity for a proposed road.

The results from the Direct Shear Test show a cohesion of 25 kPa and φ of 30°, informing the structural design and necessary pavement thickness.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In the shear test, we must not forget, Cohesion and friction, the results we beget.

Stories

Imagine a climber's rope holding the mountain—the harder he pulls (shears), the more tension on the cable until it snaps. This is like a soil's cohesive hold under stress until its strength fails.

Memory Tools

Use 'CIF' - Cohesion, Internal friction, and Failure—these remind us of the key outcome of the Direct Shear Test.

Acronyms

DST

Direct Shear Test

defines shear strength behavior in soils.

Flash Cards

Glossary

- Direct Shear Test

A laboratory test used to measure the shear strength parameters of soil.

- Cohesion (c)

A measure of the internal forces holding the soil particles together.

- Internal Friction Angle (φ)

An angle that represents the friction between particles in the soil.

- Failure Envelope

A curve plotted on a graph representing the relationship between shear and normal stresses at failure.

Reference links

Supplementary resources to enhance your learning experience.