Aggregate Gradation Control

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Aggregate Gradation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss aggregate gradation control. Can anyone tell me why it's essential in asphalt mixes?

I think it’s about how the sizes of the stones interact with each other.

Exactly, Student_1! Proper gradation ensures that smaller particles fill the gaps between larger ones, which improves stability. Can someone explain what might happen if we have an undesirable gradation?

It could lead to weak spots in the pavement or even cracking, right?

Correct! Poor gradation can weaken the overall performance of the pavement. So, achieving an optimal mix leads to enhanced durability.

How do we achieve this balance?

Great question! We utilize gradation control zones to specify the acceptable distributions of particle sizes. This helps prevent undesirable mixtures.

Can you explain more about those control zones?

Certainly! Control zones restrict certain sizes and ensure stability. They help in plotting gradation to visualize the distribution effectively. Let’s recap: controlling gradation helps enhance pavement stability and durability.

Gradation Plots

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's delve deeper into gradation plots. Who can share how these plots might help engineers?

They help you see if you're meeting gradation requirements, right?

Absolutely, Student_2! They provide a visual representation of how the particle sizes are distributed. Why is this visualization important?

It helps identify whether adjustments are needed to improve stability or durability.

Exactly! By interpreting these plots, we can make informed adjustments to the mix. What factors should we consider while analyzing them?

The ratios of fine to coarse aggregates would be important?

Very true! The right balance is critical for optimal performance. In summary, gradation plots are essential tools for ensuring mixtures are balanced and meet performance specifications.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Aggregate gradation control involves the use of specified gradation zones to prevent undesirable particle size distribution. Effective gradation plots offer insight into balancing durability and stability in asphalt mix designs, which is crucial for ensuring long-lasting pavement performance.

Detailed

Aggregate Gradation Control

In the realm of pavement engineering, aggregate gradation refers to the distribution of particle sizes within a given aggregate sample. Proper gradation is critical for ensuring the performance characteristics of pavement materials. This section outlines the importance of controlling particle size distributions through designated gradation control zones, which help to mitigate undesirable properties in asphalt mixes.

Key aspects of aggregate gradation include:

- Gradation Control Zones: These zones are established to restrict the frequencies and proportions of certain particle sizes that may adversely affect the mix. They are essential for optimizing both the stability and durability of pavement under various traffic and environmental conditions.

- Gradation Plots: These graphical representations allow engineers to evaluate and ensure the desired balance between stability and durability. By analyzing these plots, engineers can make informed decisions to refine the asphalt mixture, promoting its long-term performance and resistance to wear.

Overall, effective aggregate gradation control is crucial in the Superpave method as it directly influences the structural integrity and longevity of pavement systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Gradation Control Zones

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

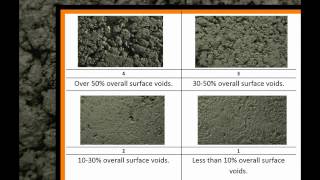

• Use of gradation control zones to restrict undesirable particle size distributions.

Detailed Explanation

Gradation control zones refer to specific ranges of particle sizes that are considered acceptable in asphalt mixtures. By imposing restrictions on the size distribution of the aggregate particles, engineers can designate which sizes are optimal for achieving the desired performance characteristics of the pavement. These zones help prevent the use of aggregates that may lead to poorer performance, such as those that are too angular or too flat.

Examples & Analogies

Think of this like baking a cake. If you were to use all flour with large lumps, the cake wouldn't bake evenly and would be unpleasant to eat. Similarly, using aggregates outside the specified gradation control zones can lead to a poorly performing pavement.

Balancing Stability and Durability

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Gradation plots are used to ensure a balance between stability and durability.

Detailed Explanation

Gradation plots visually represent the distribution of aggregate sizes in a mix. This graphical tool helps engineers ensure that the aggregate mix achieves a balance between stability (how well it can support loads without deforming) and durability (how well it withstands wear and environmental factors). By analyzing these plots, engineers can adjust the composition of the aggregate to fit within the optimal ranges for both characteristics.

Examples & Analogies

Consider a sports team. To win, you need a balance of strong players (stability) and clever strategies (durability). Just like a team needs both to succeed, a pavement mix needs a good balance of different aggregate sizes to function effectively.

Key Concepts

-

Aggregate Gradation: Refers to how well the particle sizes are distributed in an aggregate mixture.

-

Gradation Control Zones: These zones define acceptable ranges for particle sizes to ensure performance.

-

Gradation Plots: Visual aids that help engineers assess and balance the mix of aggregate sizes.

Examples & Applications

In asphalt mix design, improper particle size distribution can lead to cracking. For instance, too many fine particles without enough coarse aggregates can result in a weak mix.

An engineer uses a gradation plot to verify that the mix meets performance specifications, adjusting the proportions of aggregates as needed.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For solids that bind, mix your sizes, and you'll find, a pavement strong and refined.

Stories

Once there was a mix of stones, some tiny and some big as bones. They fought and caused cracks, until, one day, they aligned in their stacks, forming a strong, unyielding pavement.

Memory Tools

BDS (Balance-Derive-Stabilize) - Balance aggregate sizes, Derive performance characteristics, Stabilize pavement durability.

Acronyms

GRA (Gradation-Restriction-Assessment) - To remember why gradation matters

Restrict undesirable sizes to Assess balance in mixes.

Flash Cards

Glossary

- Aggregate Gradation

The distribution of particle sizes within a given aggregate sample.

- Gradation Control Zones

Specified ranges that restrict undesirable distributions of particle sizes.

- Gradation Plots

Graphical representations that display the particle size distribution within aggregates.

Reference links

Supplementary resources to enhance your learning experience.