The Superpave Method

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Superpave

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Alright class, let's dive into the Superpave Method. It was developed in the 1990s as part of the SHRP to enhance asphalt pavement performance. Can anyone tell me what that means?

Does it mean they wanted pavements that last longer?

Exactly, Student_1! The focus is on durability and performance. The method considers climate conditions, traffic loading, and material properties to create a better asphalt mix.

So, it’s about how the pavement behaves under different conditions?

Right! This approach allows for a more specific design that aims to meet real-world performance needs.

What are the actual components of the Superpave system?

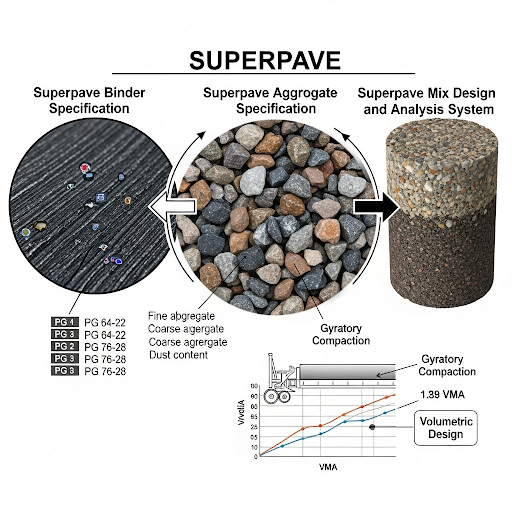

Great question, Student_3! It consists of three main components: Superpave Binder Specification, Superpave Aggregate Specification, and the Mix Design and Analysis System. Let's keep exploring these!

In summary, the Superpave Method strives to improve pavement life through performance-based design.

Understanding Components

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's break down those components! What do you think a Superpave Binder Specification entails?

Is it about the type of asphalt used?

Correct, Student_4! It focuses on performance-graded binders which suit specific temperature ranges. For example, PG 64-22 means it performs well up to 64°C and as low as -22°C.

What about aggregate specifications? Are they as important?

Absolutely, Student_1! The Superpave Aggregate Specification ensures the quality of materials used. Characteristics like angularity and gradation are critical for stability.

How about the mix design then?

The mix design involves steps to analyze materials and create a formula that meets specific volumetric criteria. It's all about simulating real-world conditions to achieve optimal results.

In summary, each component plays a vital role in achieving the desired performance standards for asphalt pavements.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Developed under the Strategic Highway Research Program (SHRP), the Superpave Method emphasizes a scientific approach to asphalt pavement design. It incorporates performance characteristics that consider environmental and load conditions to enhance sustainability and durability of pavements.

Detailed

The Superpave Method

The Superpave (Superior Performing Asphalt Pavements) Method is a comprehensive system devised to improve pavement performance by addressing its design through a performance-based lens. Developed by the Strategic Highway Research Program (SHRP) in the 1990s, it emphasizes crucial factors such as climate conditions, traffic loading, and material properties in its approach. In essence, the Superpave system redefines asphalt mix design by focusing on three primary components:

- Superpave Binder Specification: This component involves performance-graded binders tailored to specific temperature ranges, ensuring optimal performance across varying conditions.

- Superpave Aggregate Specification: This focuses on the quality and properties of aggregate materials used in the asphalt mix, applying stringent standards to ensure durability and stability.

- Superpave Mix Design and Analysis System: This specifies the steps for selecting materials and evaluating mixtures through precise procedures to guarantee optimal performance.

Through its holistic framework, the Superpave Method aims to produce pavements that are not only durable but also cost-effective throughout their lifecycle, making it a pivotal advancement in modern pavement engineering.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Background and Development

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The Superpave system was developed under the SHRP (Strategic Highway Research Program) in the 1990s to improve pavement performance. It introduced a scientific, performance-based approach to asphalt mix design considering:

- Climate conditions

- Traffic loading

- Material properties

Detailed Explanation

The Superpave method was created to tackle ongoing issues related to pavement performance. It was developed as part of the Strategic Highway Research Program in the 1990s, focusing on enhancing how asphalt mixes are designed. Rather than relying on traditional methods that might overlook real-world conditions, Superpave emphasizes understanding the environment where the pavement will be laid. This is achieved by analyzing three critical factors: the climate where the pavement will be used, the amount of traffic it needs to withstand, and the specific materials used in the asphalt mix.

Examples & Analogies

Think of designing a pavement like preparing a meal. If you are making a dish, you consider the local ingredients (material properties), the cooking method (traffic loading), and the weather conditions (climate). Just as some meals perform better under specific cooking conditions, pavements function better when tailored to their specific environment and use.

Components of Superpave System

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Superpave Binder Specification

- Superpave Aggregate Specification

- Superpave Mix Design and Analysis System

Detailed Explanation

The Superpave system consists of three main components that work together to ensure high-quality asphalt pavement. The binder specification defines the quality and characteristics of the asphalt binder, which is the glue that holds everything together. The aggregate specification sets guidelines for the types of stones and materials that can be included, ensuring they are suitable for creating durable pavements. Finally, the mix design and analysis system outlines the process for combining these materials to achieve optimal performance characteristics, ultimately leading to longer-lasting pavements.

Examples & Analogies

Imagine building a solid structure like a skyscraper. Just as you need high-quality materials like steel and concrete (binder and aggregate specifications) and a well-planned blueprint (mix design and analysis system) for the construction of the building, pavements require specific guidelines and systems to ensure that they are safe and durable against loads and environmental effects.

Key Concepts

-

Superpave Method: Focuses on performance through climate, traffic, and material consideration.

-

Performance-Graded Binder: Binders that correspond to specific temperature performance.

-

Aggregate Specification: Requirement standards for aggregate materials used.

Examples & Applications

An example of a PG binder is PG 64-22, which indicates it can withstand temperatures from -22°C to 64°C.

Superpave Aggregate Specification includes learning about coarse aggregate angularity and its effect on stability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Superpave is the way, for roads that last and stay!

Stories

Imagine building a road that needs to survive heavy rain and traffic. Superpave was like a tailor, customizing asphalt to withstand the toughest conditions.

Memory Tools

Remember GAB for Superpave components: G for Gyratory design, A for Aggregate quality, B for Binder grade.

Acronyms

PAVE

Performance

Aggregates

Voids

Ends well!

Flash Cards

Glossary

- Superpave Method

A performance-based approach to asphalt mix design that considers traffic, climate, and material properties.

- PerformanceGraded Binder

A binder classified according to its performance at specific temperature ranges.

- Aggregate Specification

Guidelines dictating the properties and qualities of aggregates used in asphalt mixtures.

Reference links

Supplementary resources to enhance your learning experience.