Performance-Based Specifications and Superpave Method

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Performance-Based Specifications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome everyone! Today, we're diving into Performance-Based Specifications, or PBS. Can anyone tell me what they think PBS means?

Is it about how well something performs instead of just following certain rules?

Exactly! PBS focus on the performance outcomes we expect from pavement structures. This means we define success based on measurable results. Why do you think this is important?

It seems like it could help improve the quality of roads since it measures actual performance.

Great observation! PBS promotes quality by setting clear performance criteria. Remember, this enables innovation as contractors can choose how to achieve these goals. Let's summarize: PBS is about what the pavement should do rather than how to build it.

Objectives of PBS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about the objectives of PBS. Can anyone recall what some of those objectives might be?

I think it’s about ensuring quality and maybe reducing costs?

That's right! PBS aim to ensure quality through measurable criteria, promote innovation, and reduce lifecycle costs. It also helps minimize disputes later. How do you think these objectives affect contractors?

They probably have more flexibility and can use their methods as long as they meet the performance goals.

Exactly! The flexibility encourages creative solutions. Let’s wrap this up: PBS objectives are about quality, innovation, cost-effectiveness, and minimizing conflicts.

Components and Testing in the Superpave Method

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's shift our focus to the Superpave Method. Can anyone tell me why Superpave was developed?

It was to improve asphalt performance by considering different factors like traffic and climate, right?

Correct! Superpave was established to provide a more scientific and performance-based asphalt mix design. Now, what are some critical components of the Superpave system?

There’s the binder specification and aggregate specification.

Absolutely! Those are crucial. And how do we test if our asphalt mix will perform as expected?

Using tests like Dynamic Modulus Test and Wheel Tracking Test!

Precisely! Various tests help evaluate different performance parameters. Let's have a quick recap: Superpave focuses on performance-based design, integrating traffic, climate, and thorough testing methods.

Parameters in Performance Evaluation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will explore the parameters that are evaluated in PBS. Can anyone list a few parameters that help assess asphalt performance?

Rutting resistance and fatigue cracking resistance are two examples!

Excellent! We also consider thermal cracking resistance, moisture susceptibility, and skid resistance. Why are these parameters vital?

They provide insights into how the pavement will perform over time and under various conditions!

That's spot on! Understanding these performance parameters is crucial for planning maintenance and ensuring safety. Let’s summarize: key parameters include rutting, cracking, moisture resistance, and skid resistance.

Implementing the Superpave Method

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s discuss the implementation of the Superpave Method. What are some challenges we might encounter when adopting Superpave?

I think the cost of the equipment is a big issue!

Correct! The high costs and the need for skilled personnel can be significant barriers. What other factors might affect its implementation?

Also, there’s the requirement for updated guidelines to integrate with local standards.

Yes! Updated guidelines are crucial. Let's wrap up this session: implementing the Superpave Method involves overcoming challenges such as costs, manpower, and regulatory compatibility.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section outlines the principles of Performance-Based Specifications (PBS), which focus on the performance outcomes of pavement structures instead of materials and techniques. It also explains the Superpave Method, developed to enhance asphalt performance by considering environmental and traffic factors, including its components, mix design procedure, and evaluation methods.

Detailed

Detailed Summary

Introduction

The transition to Performance-Based Specifications (PBS) marks a significant evolution in pavement engineering, moving from traditional prescriptive methods to a focus on measurable performance outcomes, such as durability and resistance to distress.

15.1 Performance-Based Specifications (PBS)

- Definition and Concept: PBS define pavements in terms of what they should achieve in performance, rather than dictating specific material specifications.

- Objectives of PBS: Quality assurance through measurable criteria, promotion of innovation among contractors, extended service life, and reduced lifecycle costs are primary goals, along with minimizing disputes during and after construction.

- Types of PBS: This section discusses three types - End-Result Specifications (ERS), Performance-Related Specifications (PRS), and Warranty-Based Specifications, each emphasizing different aspects of performance evaluation.

- Parameters in Performance Evaluation: Key performance metrics include rutting resistance, fatigue cracking, thermal cracking, moisture susceptibility, skid resistance, and smoothness.

- Testing Protocols: This includes various testing methods like the Dynamic Modulus Test and Wheel Tracking Test for evaluating pavement performance.

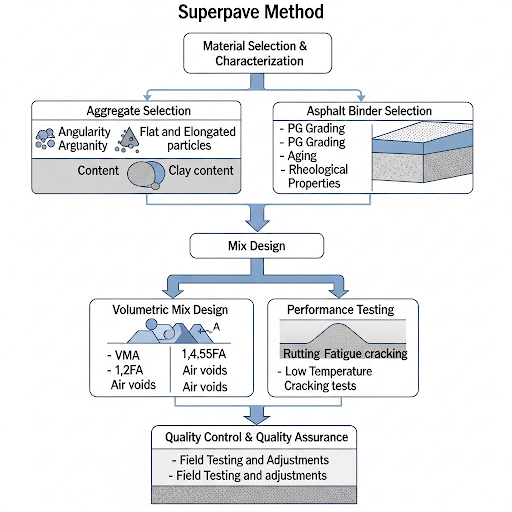

15.2 The Superpave Method

- Background and Development: Developed under the SHRP in the 1990s, the Superpave Method incorporates environmental conditions and traffic loads into a scientific, performance-based approach for asphalt design.

- Components of Superpave: It includes specifications for binder, aggregate, and a systematic mix design and analysis process.

- Superpave Asphalt Binder Specification: Binders are classified by performance grades (PG), indicated as PG XX-YY, based on temperature ranges.

- Superpave Aggregate Specifications: Focus is on aggregate properties and gradation control to determine their suitability in asphalt mixtures.

- Mix Design Procedure: This includes material selection, sample preparation, compaction, volumetric analysis, and moisture susceptibility testing.

- Performance Prediction Models: The section wraps up by describing models for predicting long-term performance of asphalt mixes based on historical data.

Conclusion

The chapter emphasizes the significance of PBS and the Superpave Method in modernizing pavement engineering, offering a structured approach that ensures longevity and durability in pavement systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Performance-Based Specifications

Chapter 1 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Traditional methods for specifying pavement materials and construction often rely on prescriptive specifications, which focus on procedures and material compositions rather than the expected performance of the finished pavement. With advancements in pavement engineering, there's a significant shift toward Performance-Based Specifications (PBS) that define quality in terms of measurable pavement performance outcomes such as durability, resistance to rutting, and cracking. Coupled with this approach is the Superpave (Superior Performing Asphalt Pavements) Method, a product of the Strategic Highway Research Program (SHRP) in the United States, which modernized asphalt mix design by incorporating traffic loading, climate conditions, and material properties.

Detailed Explanation

This chunk introduces the concept of Performance-Based Specifications, contrasting them with traditional prescriptive methods. Rather than dictating how materials should be used, PBS focuses on what the pavement should achieve in terms of performance, such as its durability and ability to resist issues like rutting and cracking. The Superpave method is highlighted as a significant advancement in this field, as it considers various important factors like traffic and climate in the asphalt mix design process.

Examples & Analogies

Think of it like cooking from a recipe versus cooking based on taste. A traditional recipe is very specific about the ingredients and steps, while cooking based on taste allows you to adjust the flavors and textures based on your preferences. In the same way, Performance-Based Specifications let engineers focus on the end result of pavement performance rather than just following strict material guidelines.

Definition and Concepts of Performance-Based Specifications

Chapter 2 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Performance-Based Specifications are specifications that describe the desired outcomes or behavior of a pavement structure, rather than the specific materials or construction techniques to be used. These specifications emphasize what the pavement should do, rather than how it should be constructed.

Detailed Explanation

Here, we delve into what Performance-Based Specifications (PBS) are. They define how a pavement is expected to perform instead of dictating the specifics of construction methods or materials. This shift allows for flexibility in design and construction, focusing primarily on the functionality and longevity of the pavement.

Examples & Analogies

Imagine if you tell a contractor, 'I want a road that can last ten years without major repairs' instead of saying, 'Use these exact types of asphalt and concrete.' This way, the contractor has room to innovate and use the best methods available to meet that goal.

Objectives of Performance-Based Specifications

Chapter 3 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Ensure quality through measurable performance criteria.

• Promote innovation by allowing contractors flexibility in achieving performance goals.

• Enhance service life and reduce life-cycle costs.

• Minimize disputes during and after construction.

Detailed Explanation

This chunk outlines the main objectives of using Performance-Based Specifications. They ensure that quality is maintained through clear, measurable criteria, providing a framework within which contractors can operate creatively. The goals are not only to increase the lifespan of pavements and lower costs over time but also to reduce conflicts that could arise during construction.

Examples & Analogies

Think about setting goals for personal fitness. Instead of saying 'do these exact exercises', you might declare, 'I want to run a marathon'. This gives you room to choose your exercises and methods while still focusing on achieving the overall goal of completing the marathon.

Types of Performance Specifications

Chapter 4 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• End-Result Specifications (ERS): Focus on final product characteristics, with incentives and penalties based on deviations from specified performance.

• Performance-Related Specifications (PRS): Incorporate relationships between construction quality characteristics (e.g., air voids, binder content) and future pavement performance.

• Warranty-Based Specifications: Require the contractor to guarantee performance for a defined period.

Detailed Explanation

This segment categorizes three types of Performance-Based Specifications. End-Result Specifications are oriented towards the final characteristics of the pavement and include penalties for failing to meet these characteristics. Performance-Related Specifications create a link between quality during construction and future performance, encouraging quality control. Warranty-Based Specifications obligate contractors to stand by their work, guaranteeing specific performance levels for a defined time.

Examples & Analogies

Consider how different warranties work for electronics. Some products may just promise to work as described (End-Result), while others link their performance to quality checks during the manufacturing process (Performance-Related), and some might offer a warranty promising repair or replacement if it fails within a certain period (Warranty-Based).

Parameters in Performance Evaluation

Chapter 5 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Rutting Resistance

• Fatigue Cracking Resistance

• Thermal Cracking Resistance

• Moisture Susceptibility

• Skid Resistance

• Smoothness and Ride Quality

Detailed Explanation

This chunk lists critical parameters that are evaluated to determine the performance characteristics of the pavement. These include how well the pavement can resist rutting and cracking from fatigue and temperature changes, how it behaves in wet conditions, its smoothness for vehicle passage, and its overall ride quality. Evaluating these factors helps to ensure that the pavement will perform well under various conditions.

Examples & Analogies

It's like evaluating a vehicle before buying it. You check for smooth handling, how it performs in rain, and its durability over time. Similarly, these parameters help engineers assess if a pavement will perform well across different scenarios.

Testing Protocols for Performance Evaluation

Chapter 6 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Dynamic Modulus Test

• Indirect Tensile Strength Test

• Wheel Tracking Test

• Hamburg Wheel-Track Test

• Asphalt Pavement Analyzer (APA)

Detailed Explanation

Here, we discuss various testing protocols used to measure the performance characteristics of pavement materials. Each of these tests serves a specific purpose in evaluating how well the materials can withstand various stresses and conditions they will face in the real world.

Examples & Analogies

Just like a car undergoes various tests for safety, performance, and durability before it hits the market, pavement materials are subjected to numerous tests to ensure they can handle the demands of traffic and weather.

The Superpave Method Overview

Chapter 7 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The Superpave system was developed under the SHRP (Strategic Highway Research Program) in the 1990s to improve pavement performance. It introduced a scientific, performance-based approach to asphalt mix design considering:

• Climate conditions

• Traffic loading

• Material properties

Detailed Explanation

This chunk introduces the Superpave method, which was established to enhance the performance of pavements. This modern approach considers various essential factors, such as climate, traffic loads, and material properties, making it a comprehensive improvement over traditional methods.

Examples & Analogies

Just as you might tailor your clothing choices based on the weather and what activities you'll be doing, the Superpave method customizes asphalt mix designs to suit the specific environmental and usage scenarios they will face.

Components of the Superpave System

Chapter 8 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Superpave Binder Specification

- Superpave Aggregate Specification

- Superpave Mix Design and Analysis System

Detailed Explanation

This segment highlights the core components of the Superpave system. It starts with the specification for binders, which outlines how the asphalt binder is to be tested and characterized, then details the aggregate specifications, and finally, introduces the mix design and analysis process that integrates these elements to create a reliable pavement structure.

Examples & Analogies

Think of the Superpave components like ingredients in a recipe. Each ingredient (binder and aggregates) must meet certain standards, and they are combined in a specific way (mix design) to create a well-performing dish—the pavement.

Key Concepts

-

Transition to Performance-Based: Movement from prescriptive to performance-based specifications in pavement engineering.

-

Superpave Method: A scientific method for asphalt design considering multiple performance factors.

-

PBS Objectives: Goals like quality assurance, innovation, life cycle cost reduction, and minimizing disputes.

-

Performance Parameters: Metrics like rutting resistance and moisture susceptibility that evaluate asphalt performance.

Examples & Applications

An example of PBS: A highway that receives a performance guarantee from the contractor to ensure it withstands heavy truck traffic for 20 years.

In Superpave, PG 64-22 indicates a binder suitable for a maximum temperature of 64°C, ensuring proper performance in that climate.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

PBS guarantees roads that are strong and safe, without the hassles of disputes or compromise in faith.

Stories

Once upon a time, there was a pavement contractor who only focused on materials to build roads. But when Performance-Based Specifications became popular, they learned that how the road performs matters more than what it's made of. By following PBS, they built roads that lasted longer and faced fewer complaints!

Memory Tools

To remember PBS objectives, think: Q.I.L.D. - Quality, Innovation, Life-cycle costs, Disputes minimized.

Acronyms

Use 'R.F.M.S.' to remember key performance parameters

Rutting

Fatigue

Moisture

Skid.

Flash Cards

Glossary

- PerformanceBased Specifications (PBS)

Specifications that focus on the desired outcomes of pavement performance instead of specific construction techniques.

- Superpave Method

A performance-based asphalt mix design system considering climate, traffic, and material properties developed by SHRP.

- EndResult Specifications (ERS)

Specifications that emphasize the final product characteristics, including incentives for meeting performance goals.

- PerformanceRelated Specifications (PRS)

Specifications that link construction quality to future pavement performance.

- WarrantyBased Specifications

Specifications requiring contractors to guarantee performance for a specified time.

- Dynamic Modulus Test

A test that measures the stiffness of asphalt mixtures in response to loading.

- Rut Resistance

The ability of a pavement to withstand deformation under load, preventing ruts formation.

- Fatigue Cracking

Cracks that occur due to repeated traffic loading and environmental factors.

- Moisture Susceptibility

The tendency of asphalt to deteriorate when exposed to moisture.

- Skid Resistance

The ability of the pavement surface to provide traction and prevent slipping.

Reference links

Supplementary resources to enhance your learning experience.