Performance-Based Specifications (PBS)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to PBS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re going to discuss Performance-Based Specifications, or PBS. These specifications focus on the desired outcomes of a pavement structure rather than detailing the exact materials and construction methods. Why do you think this approach is beneficial?

It seems like it would allow for better adaptability in construction techniques depending on different conditions.

Absolutely! That adaptability promotes innovation. PBS encourages contractors to use their expertise to meet performance goals while focusing on the end product.

So, PBS is about measuring success based on the performance of the pavement rather than how it's built?

Exactly! It highlights the importance of durable and resilient pavement structures.

Objectives of PBS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss the objectives of PBS. Understanding these objectives is crucial for grasping the significance of this approach. Can anyone list some objectives?

One objective is to ensure quality through measurable performance criteria.

Another is to enhance the service life and reduce lifecycle costs.

Great points! Minimizing disputes during and after construction is another primary goal. PBS is designed to clarify expectations and reduce conflicts.

So, it helps everyone stay aligned on what needs to be achieved?

Exactly! Clear specifications reduce misunderstandings.

Types of Performance Specifications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

PBS can take various forms. Who can tell me about some types of performance specifications?

There's End-Result Specifications, which focus on final product characteristics.

And Performance-Related Specifications that link construction quality with future performance?

Exactly! PBS includes Warranty-Based Specifications that require contractors to guarantee performance for a defined period.

That sounds like it puts a lot of responsibility on contractors!

Indeed, but it also encourages higher quality work and accountability.

Parameters in Performance Evaluation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about the key parameters that are assessed during the performance evaluation of pavements. What do you think they might include?

Maybe things like rutting resistance and fatigue cracking resistance?

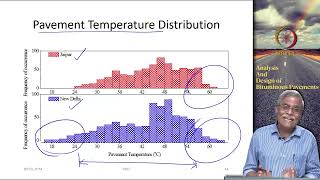

And thermal cracking resistance too!

Correct! Other important parameters include moisture susceptibility, skid resistance, and smoothness. These factors are vital for determining the overall durability of pavement.

So these parameters help ensure the pavement performs well under real conditions?

Exactly right! Each parameter targets potential failure modes.

Testing Protocols

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's discuss the various testing protocols used to evaluate performance in PBS. Can anyone name a few?

I remember the Dynamic Modulus Test is one of them.

And the Wheel Tracking Test?

Exactly, both of them are important in assessing the material's performance. The Hamburg Wheel-Track Test is also crucial in measuring rutting potential.

These tests seem integral for ensuring quality.

Absolutely! They provide the data needed to ensure pavements meet the outlined performance specifications.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

PBS emphasizes the expected performances of pavement such as durability and resistance to damage rather than detailing construction methods. Its objectives include ensuring quality through measurable criteria, promoting innovation, and minimizing disputes. Various types of PBS such as End-Result Specifications and Warranty-Based Specifications are employed to assure performance through measurable outcomes.

Detailed

Performance-Based Specifications (PBS)

Performance-Based Specifications (PBS) represent a significant evolution in how pavement quality is defined. Instead of prescribing the exact materials and construction techniques, PBS outlines the expected behaviors and outcomes of pavement structures. This shift allows for flexibility and innovation in construction methods while still requiring adherence to performance goals.

Objectives of PBS

The main objectives of PBS include:

1. Ensuring quality through measurable performance criteria.

2. Promoting innovation by allowing contractors the flexibility to achieve performance goals.

3. Enhancing the service life of pavement and lowering life-cycle costs.

4. Minimizing disputes between contractors and project owners during and after construction.

Types of Performance Specifications

PBS can take on various forms:

- End-Result Specifications (ERS) focus on the final characteristics of the product and include incentives or penalties for performance deviations.

- Performance-Related Specifications (PRS) consider construction quality characteristics that relate to future pavement performance.

- Warranty-Based Specifications entail contractors guaranteeing performance for a set period.

Parameters in Performance Evaluation

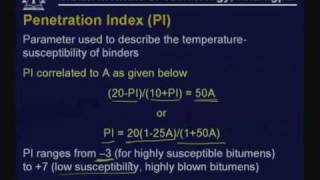

Key parameters used in performance evaluation include rutting resistance, fatigue cracking resistance, thermal cracking resistance, moisture susceptibility, skid resistance, and smoothness.

Testing Protocols

Various testing protocols, such as the Dynamic Modulus Test and the Hamburg Wheel-Track Test, are used to assess the performance of pavement materials under specified conditions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition and Concept

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Performance-Based Specifications are specifications that describe the desired outcomes or behavior of a pavement structure, rather than the specific materials or construction techniques to be used. These specifications emphasize what the pavement should do, rather than how it should be constructed.

Detailed Explanation

This concept highlights a shift from traditional specifications, which focus on the materials and methods used to build a pavement, towards a focus on the performance outcomes of the pavement itself. Instead of saying 'use this type of asphalt here', PBS says 'the pavement must withstand this amount of stress and not crack for a certain number of years'. This allows for more flexibility in how contractors meet these performance goals.

Examples & Analogies

Imagine you are baking a cake. A traditional recipe tells you to use flour, sugar, and eggs in specific amounts (prescriptive). In contrast, a performance-based approach might say 'create a cake that rises well and tastes sweet', allowing you to use different ingredients as long as the result is delicious and well-risen.

Objectives of PBS

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Ensure quality through measurable performance criteria.

• Promote innovation by allowing contractors flexibility in achieving performance goals.

• Enhance service life and reduce life-cycle costs.

• Minimize disputes during and after construction.

Detailed Explanation

The objectives of Performance-Based Specifications serve several important functions. First, they set measurable criteria that can be quantitatively assessed, ensuring that the pavement will meet necessary standards. By allowing contractors the freedom to innovate, PBS encourages new techniques and materials, which can lead to better outcomes. This approach also aims to extend the lifespan of the pavement while keeping costs manageable over its lifetime and helping to reduce conflicts between project stakeholders by clearly defining performance expectations.

Examples & Analogies

Think of PBS like a sports tournament where each team is given a clear goal to score a certain number of points. Coaches can choose any strategy to achieve that score. This encourages creativity and can result in exciting and unexpected plays, just as PBS encourages innovative construction practices to meet quality goals.

Types of Performance Specifications

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• End-Result Specifications (ERS): Focus on final product characteristics, with incentives and penalties based on deviations from specified performance.

• Performance-Related Specifications (PRS): Incorporate relationships between construction quality characteristics (e.g., air voids, binder content) and future pavement performance.

• Warranty-Based Specifications: Require the contractor to guarantee performance for a defined period.

Detailed Explanation

Performance specifications can be categorized into three types. End-Result Specifications focus on what the finished pavement should achieve and introduce financial incentives or penalties to ensure compliance. Performance-Related Specifications look at how the quality of construction directly influences future performance, linking construction methods to long-term durability. Warranty-Based Specifications require contractors to stand by their work, guaranteeing that the pavement will meet performance standards for a certain time frame.

Examples & Analogies

Consider the warranties we get when we buy a new appliance. If it fails, the company is obligated to fix it. Similarly, in construction, if a contractor uses a Warranty-Based Specification, they are like the appliance company, ensuring that the pavement they build lasts a set number of years without issue, which provides peace of mind to the owner.

Parameters in Performance Evaluation

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Rutting Resistance

• Fatigue Cracking Resistance

• Thermal Cracking Resistance

• Moisture Susceptibility

• Skid Resistance

• Smoothness and Ride Quality

Detailed Explanation

When evaluating pavement performance, several key parameters are assessed. Rutting resistance measures the pavement's ability to withstand deformation under heavy traffic loads. Fatigue cracking resistance refers to how well the surface can resist cracks due to repeated stress. Thermal cracking resistance ensures the pavement can handle temperature variations without cracking. Moisture susceptibility evaluates the pavement's reaction to water, while skid resistance measures how well tires grip the surface. Finally, smoothness and ride quality evaluate the user experience for drivers.

Examples & Analogies

Think of a high-performance vehicle that needs high-quality tires to perform well on the road. Each of these parameters serves as a different aspect of what makes a tire effective on a variety of surfaces and conditions, ensuring safety and comfort for those using the road.

Testing Protocols

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Dynamic Modulus Test

• Indirect Tensile Strength Test

• Wheel Tracking Test

• Hamburg Wheel-Track Test

• Asphalt Pavement Analyzer (APA)

Detailed Explanation

Various testing protocols are utilized to determine the performance characteristics of pavement materials. The Dynamic Modulus Test measures how a material behaves under stress, while the Indirect Tensile Strength Test assesses how well asphalt can resist cracking. The Wheel Tracking Test simulates the effects of traffic over time to measure rutting potential, and the Hamburg Wheel-Track Test specifically assesses moisture susceptibility and resistance to permanent deformation. The Asphalt Pavement Analyzer (APA) provides a comprehensive analysis of pavement performance under simulated loading conditions.

Examples & Analogies

Imagine a fitness trainer who evaluates an athlete's performance using different tests for strength, endurance, and flexibility. Each test helps pinpoint areas for improvement or confirms that the athlete is ready for competition. In a similar vein, these tests help engineers determine if the materials used in pavement are up to the task.

Key Concepts

-

Performance-Based Specifications (PBS): Focus on expected outcomes of pavement construction rather than methods.

-

Types of Specifications: Includes ERS, PRS, and Warranty-Based Specifications.

-

Performance Evaluation Parameters: Includes rutting resistance, thermal cracking resistance, and skid resistance.

-

Testing Protocols: Various methods used to assess material performance.

Examples & Applications

An example of ERS is a highway project that incentivizes contractors to exceed minimum performance metrics for durability.

A warranty-based specification could require a contractor to guarantee the pavement's performance for 5 years, ensuring any necessary repairs are covered.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

PBS is the way to go, for quality that we can show.

Stories

Imagine a contractor who is given freedom in how they build a highway. Instead of being told to use a specific brand of asphalt, they're given criteria like 'no cracking', 'no rutting', encouraging them to innovate while being held accountable.

Memory Tools

To remember key PBS parameters, remember 'RFTMS': Rutting, Fatigue, Thermal, Moisture, Skid.

Acronyms

PBS

Performance

Benefits

Specifications.

Flash Cards

Glossary

- PerformanceBased Specifications (PBS)

Specifications that describe the desired outcomes or behavior of a pavement structure rather than the specific materials or construction techniques.

- EndResult Specifications (ERS)

Specifications that focus on final product characteristics, providing incentives and penalties based on performance deviations.

- PerformanceRelated Specifications (PRS)

Specifications that incorporate relationships between construction quality characteristics and future pavement performance.

- WarrantyBased Specifications

Specifications that require the contractor to guarantee performance for a defined period.

- Parameters in Performance Evaluation

Key criteria used to assess the performance of pavement, including resistance to rutting, fatigue, and thermal cracking.

- Testing Protocols

Standardized methods used to assess the performance characteristics of pavement materials.

Reference links

Supplementary resources to enhance your learning experience.