Performance-Graded (PG) Binder

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding PG Binders

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re going to dive into Performance-Graded or PG binders. These are essential for understanding pavement durability. Can anyone tell me what PG stands for?

I think it stands for ‘Performance Grade’!

Exactly! PG binders are classified based on performance at specific temperature ranges. They use the format PG XX-YY. Can anyone explain what each part of that means?

I think XX is the maximum temperature?

Correct! And YY is the minimum pavement design temperature. So, a PG 64-22 means a maximum of 64°C and a minimum of -22°C. Let’s remember that with the mnemonic: *“64 in the heat, 22 in the sleet.”* Any questions on that?

Why do we care about these specific temperatures?

Great question! These temperatures provide critical information that ensures pavements perform well under local climate conditions.

Importance of PG Binders in Pavement Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about why PG binders are important in pavement design. What do you think would happen if we chose the wrong binder?

Maybe the pavement wouldn’t last as long?

Exactly! Using the appropriate PG binder helps prevent issues like cracking and rutting, which leads to longer-lasting pavements. Remember: *“Right Binder, Right Time, Right Place.”* Can anyone give an example of how the wrong temperature range would affect performance?

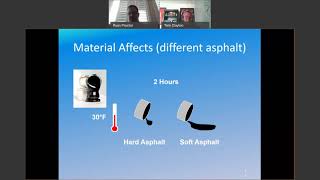

If a binder isn’t suited for high heat, it might become too soft?

Precisely! And softness can lead to rutting. On the flip side, if it’s too stiff for colder temperatures, it can crack. This balance is crucial for optimal pavement performance.

Testing and Standards for PG Binders

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss how we make sure PG binders will perform as expected. What tests do you think we do?

Maybe tests for temperature resistance?

Yes! We use tests like the Dynamic Shear Rheometer to evaluate rutting performance and the Bending Beam Rheometer to assess low-temperature cracking. This testing ensures each binder meets its performance specifications. Can anybody name a benefit of rigorous testing?

It helps avoid future pavement failures?

Exactly! Thorough testing leads to reliable outcomes, and that means fewer repairs and better cost efficiency over the pavement’s lifespan.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In the Superpave system, binders are categorized with a PG designation that indicates their expected performance at various temperature conditions, facilitating better pavement performance and longevity.

Detailed

Performance-Graded (PG) Binder

Performance-Graded (PG) Binders are a crucial component of the Superpave asphalt mix design system, which optimizes asphalt pavement performance. Binders are classified using a specific format, PG XX-YY, where XX represents the average maximum pavement temperature in degrees Celsius for a seven-day period, and YY denotes the minimum pavement design temperature. For example, a PG 64-22 binder is suitable for an average maximum temperature of 64°C and a minimum temperature of -22°C. This classification system not only helps ensure the durability and performance of pavements but also tailors the materials to specific climatic and loading conditions. Understanding the PG classification is vital for engineers seeking to implement effective pavement solutions that can withstand local environmental challenges.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Binder Classification Format

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Binders in the Superpave system are classified based on their performance at specific temperature ranges:

• Format: PG XX-YY

– XX = average 7-day maximum pavement temperature (°C)

– YY = minimum pavement design temperature (°C)

Detailed Explanation

The Performance-Graded (PG) Binder classification helps determine the suitability of a binder for different climatic conditions. The format PG XX-YY reveals two key temperature indicators.

- The 'XX' component represents the average maximum pavement temperature the binder can handle over a 7-day period, measured in degrees Celsius.

- The 'YY' component indicates the minimum temperature a pavement designed with this binder can endure. This classification ensures that the selected binder can appropriately perform in the specific temperature ranges expected at the installation site.

Examples & Analogies

Imagine you are choosing a jacket for a specific season. If it's summer, you’d look for a light jacket that can withstand higher temperatures (like PG 64), while for winter, you'd prefer a heavy coat that can keep you warm even in cold temperatures (like PG -22). Similarly, binders are chosen based on the temperatures they will face.

Example of a Performance-Graded Binder

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Example: PG 64-22 indicates suitability for 64°C max and -22°C min.

Detailed Explanation

Using the example PG 64-22, we see specific performance capabilities:

- The binder can withstand a maximum temperature of 64 degrees Celsius, which indicates its effectiveness in warm climates.

- The -22 degrees Celsius minimum indicates that this binder remains functional and does not become brittle even in cold temperatures. This ensures durability and performance in varying weather conditions.

Examples & Analogies

Think of it like a pair of shoes designed for different weather. If you buy shoes rated for extreme cold (-22°C), you don't want them to crack or break in chillier temperatures. If they also handle a maximum heat of 64°C, they won’t fall apart in hot summer. The PG classification serves a similar purpose, ensuring asphalt remains reliable under its expected temperature range.

Key Concepts

-

Temperature Performance Classification: PG binders are classified based on performance at defined temperature ranges.

-

Classification Format: PG XX-YY where XX is the maximum temperature and YY is the minimum.

-

Importance of Binder Selection: Choosing the correct binder is critical for preventing pavement issues.

Examples & Applications

PG 64-22 binder suitable for climates with high maximum temperatures of 64°C and lows of -22°C.

Using a PG 58-34 binder in colder climates helps prevent thermal cracking.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

PG binders must not fray, to keep pavements in good array.

Stories

Imagine building roads in a holiday town, you use PG 64-22, where in peak summer it’s baking and winter temp drops through. Choose wisely, or your roads will crack and-not to mention, cost you that extra buck to fix!

Memory Tools

For temperature: 'Gonna Get This’, with G for 'Gradation' and 'T' for 'Temperature', helps remember the core factors in PG classification.

Acronyms

Think of the acronym TAP - Temperature, Asphalt, Performance. It summarizes the key focus points for a binder’s grading.

Flash Cards

Glossary

- PerformanceGraded (PG) Binder

An asphalt binder classified based on its performance at specific temperature ranges.

- Dynamic Shear Rheometer (DSR)

A device used to measure the rutting and fatigue resistance of asphalt binders.

- Bending Beam Rheometer (BBR)

A device used to evaluate low-temperature cracking performance in asphalt binders.

Reference links

Supplementary resources to enhance your learning experience.