Modified Bitumen and Testing

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Modified Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re delving into modified bitumen, which is bitumen enhanced with materials such as polymers or rubber. What do you think is the reason for this modification?

Is it to improve its properties for better performance in roads?

Exactly! Modified bitumen aims to enhance flexibility, durability, and performance under varying environmental conditions. Can anyone name a common type of modified bitumen?

Polymer Modified Bitumen or PMB?

Correct! PMB is popular because it provides excellent elasticity. Remember that PMB can enhance performance through its sticky nature that helps bind aggregates effectively. It's like having a super-glue for roads!

Common Types of Modified Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss the different types of modified bitumen. Student_3, could you tell me what Crumb Rubber Modified Bitumen (CRMB) is?

Isn't it when we add rubber to the bitumen to make it tougher?

Yes, it indeed improves the toughness and durability of the material! Think of it as giving the bitumen some extra armor for better performance.

What other types are there besides PMB and CRMB?

While PMB and CRMB are the most common, there are also hybrid types that may use combinations for specific needs. Each type is designed to tackle specific performance deficiencies of regular bitumen.

Testing Modified Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Testing plays a crucial role in evaluating the modified bitumen's performance. What are some tests we perform on it?

We perform the Elastic Recovery Test, right?

Absolutely! The Elastic Recovery Test measures the ability to return to its original shape after deformation, which is vital for its flexibility. Can anyone summarize why these tests are important?

They help ensure that the modified bitumen will perform well under different conditions.

Spot on! By conducting these tests like the Softening Point and Storage Stability tests, we ensure that the bitumen remains effective and reliable in real-world situations.

Significance of Modified Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss the significance of modified bitumen in the construction industry. Why do you think it matters?

I think it makes roads last longer and withstand more wear and tear.

Exactly! Modified bitumen enhances road lifespan and performance, adapting to traffic loads and weather changes. Keeping that in mind, it's like creating a stronger, more resilient foundation for our infrastructure.

Does this mean we are using it more often in new projects now?

Absolutely! The trend is moving toward using modified bitumen where sustainability and quality are priorities.

Review of Key Concepts

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To sum up, what have we learned about modified bitumen today?

We learned that modified bitumen is enhanced to improve performance.

And that we have types like PMB and CRMB, each serving a specific purpose!

Great recollections! And remember, the testing methods are crucial for ensuring the bitumen remains functional in all conditions. Let's apply these insights moving forward!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses modified bitumen, which is enhanced with polymers, rubber, or other materials to improve its performance in pavement applications. It outlines common types of modified bitumen and discusses tests used to evaluate properties such as elastic recovery and softening point.

Detailed

Modified Bitumen and Testing

Modified bitumen represents an advancement in asphalt technology, blending conventional bitumen with additives like polymers and rubber to enhance its performance characteristics. This modification aims to address the limitations of standard bitumen and adapt to varied environmental conditions.

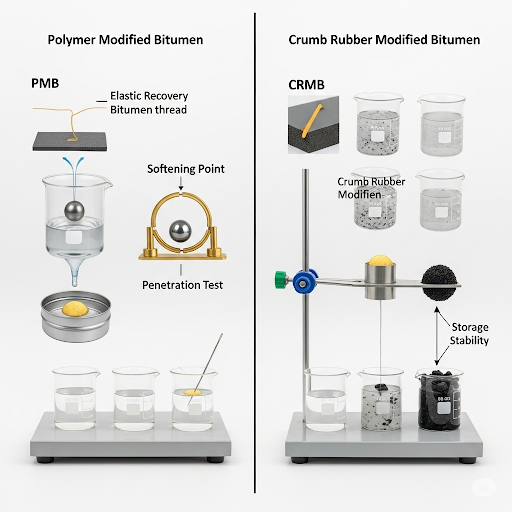

Common Types

- Polymer Modified Bitumen (PMB): Enhances elasticity and resistance to deformation.

- Crumb Rubber Modified Bitumen (CRMB): Introduces rubber particles to improve toughness and durability.

Testing for Modified Bitumen

To ensure the integrity and performance of modified bitumen, several specific tests are performed:

- Elastic Recovery: Measures the ability of bitumen to return to its original shape after deformation, indicating flexibility under loading.

- Softening Point: Obtains the temperature at which bitumen transitions to a more fluid state, important for performance in high-heat conditions.

- Penetration Test: Assesses the hardness or softness of bitumen, providing insight into its resistance properties.

- Storage Stability: Evaluates the ability to maintain consistent properties during storage without separation of components.

These assessments are crucial to verify that the modified bitumen will perform effectively under the specific demands of road and pavement applications.

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Modified Bitumen

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Modified bitumen is bitumen blended with polymers, rubber, or other materials to improve performance.

Detailed Explanation

Modified bitumen refers to a type of bitumen that has been altered by blending it with other materials, such as polymers or rubber. This is done to enhance certain properties of the bitumen, making it perform better under various conditions. By improving its ability to withstand stress and temperature changes, modified bitumen can lead to more durable road surfaces.

Examples & Analogies

Think of modified bitumen like upgrading a regular pair of shoes to a rugged version. The basic structure is still there, but the upgraded version features better materials for added strength and comfort. Just like the shoes are better suited for outdoor adventures, modified bitumen is better suited for varying weather and heavy traffic on roads.

Common Types of Modified Bitumen

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Common Types:

• Polymer Modified Bitumen (PMB)

• Crumb Rubber Modified Bitumen (CRMB)

Detailed Explanation

There are two main types of modified bitumen: Polymer Modified Bitumen (PMB) and Crumb Rubber Modified Bitumen (CRMB). PMB involves the incorporation of polymers, which can enhance flexibility and performance at high temperatures, while CRMB uses recycled rubber from tires, which adds elasticity and durability to the bitumen. These modifications help in achieving better performance characteristics compared to standard bitumen.

Examples & Analogies

Imagine a chef using different spices to enhance the flavor of a dish. In this scenario, PMB is like adding exotic spices to create a unique flavor, while CRMB is akin to incorporating local ingredients to create a more hearty and familiar taste. Both modifications serve to personalize and improve the final product—in this case, the performance of bitumen in road construction.

Tests for Modified Bitumen

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Tests for Modified Bitumen:

• Elastic recovery

• Softening point

• Penetration

• Storage stability

Detailed Explanation

To ensure the quality and performance of modified bitumen, specific tests are conducted. Elastic recovery evaluates how well the material returns to its original shape after being stretched. The softening point test measures the temperature at which the bitumen begins to flow, giving insights into its behavior under heat. The penetration test checks how soft or hard the bitumen is by measuring the depth a needle can penetrate. Lastly, storage stability tests determine how well modified bitumen maintains its properties when stored over time.

Examples & Analogies

Consider a rubber band. When you stretch it, it can return to its original shape—this is like the elastic recovery test. Now, if you heat that rubber band, it might lose its shape or become too loose, similar to the softening point test. Just as you wouldn’t want a rubber band that loses its shape or stretches too easily, we need to ensure modified bitumen maintains its properties for effective road performance.

Key Concepts

-

Modified Bitumen: Bitumen enhanced with polymers or rubber for better performance.

-

Polymer Modified Bitumen (PMB): A type known for improving elasticity and resistance.

-

Crumb Rubber Modified Bitumen (CRMB): Incorporates rubber particles to enhance toughness.

-

Elastic Recovery: Evaluates flexibility of bitumen after deformation.

-

Softening Point: Indicates the temperature at which bitumen transitions to fluid.

-

Storage Stability: Ensures the bitumen's properties remain consistent during storage.

Examples & Applications

A road using Polymer Modified Bitumen exhibits reduced cracking and longer lifespan due to enhanced elastic properties.

Crumb Rubber Modified Bitumen is effectively utilized in high-traffic areas where durability is crucial.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Modified bitumen shines bright, with rubber or polymers just right!

Stories

Imagine a road that faces storms and heat. Modified bitumen, like a superhero, battles the elements and keeps the path safe and sound.

Memory Tools

Remember PMB for Perfectly Melting Bitumen – it stays soft where it's hot!

Acronyms

CRMB

Crumb Rubber Makes Bitumen better!

Flash Cards

Glossary

- Modified Bitumen

Bitumen blended with polymers, rubber, or other materials to enhance performance.

- Polymer Modified Bitumen (PMB)

A type of modified bitumen that incorporates polymers to enhance elastic properties.

- Crumb Rubber Modified Bitumen (CRMB)

Bitumen that has been modified with rubber particles, improving toughness and durability.

- Elastic Recovery

The ability of bitumen to return to its original shape after being deformed.

- Softening Point

The temperature at which bitumen transitions to a more fluid state.

- Storage Stability

The ability of modified bitumen to maintain its properties during storage.

Reference links

Supplementary resources to enhance your learning experience.