Properties and Tests of Bitumen

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are discussing bitumen. Can anyone tell me what the primary source of bitumen is?

Isn’t it derived from crude oil?

Exactly! Bitumen comes from the fractional distillation of crude oil. This process separates lighter fuels like gasoline. Now, can anyone explain what bitumen primarily acts as in road construction?

I think it acts as a binder for aggregates.

Correct! And its effectiveness depends on its composition, which includes asphaltenes, resins, aromatics, and saturates. Does anyone remember what asphaltenes do?

Asphaltenes contribute to the stiffness of bitumen.

Right, and resins help with adhesion. So, let's keep these components in mind as we talk about bitumen's properties.

To help remember, think of A.R.A.S. (Asphaltenes, Resins, Aromatics, Saturates) as the components of bitumen.

In summary, bitumen is key in paving and is derived from crude oil, with a complex composition affecting its properties.

Desirable Properties of Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on, let’s discuss the desirable properties of bitumen. Why do you think adhesion is important?

It needs to stick well to the aggregates, right?

Absolutely! Without good adhesion, the pavement could fail. What about viscosity?

It should be fluid enough for mixing but also stiff enough when cooled.

Well said! Viscosity is essential for the mixing and pumping processes. Can anyone elaborate on why ductility is crucial as well?

Ductility helps accommodate thermal movements without cracking.

Exactly! So, these properties—adhesion, viscosity, ductility—collectively affect the performance of bitumen in pavements. Let's remember them using the acronym AVD (Adhesion, Viscosity, Ductility).

In conclusion, all these properties ensure durability, temperature resilience, and water resistance, which are vital for longevity.

Testing Bitumen Properties

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand the importance of bitumen properties, how do we evaluate them?

I remember the penetration test measures softness?

Correct! It uses a needle to measure how deep it can penetrate. What does a higher penetration value signify?

Softer bitumen!

Great! Now, how about the softening point test? What do we gain information about?

It shows at what temperature the bitumen softens.

Exactly! And this helps us understand its behavior at high temperatures. Can anyone explain the significance of specific gravity?

It's important for weight-volume conversions in pavements.

Correct! In summary, these tests—penetration, softening point, specific gravity—give us crucial insights into the quality of bitumen.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Bitumen, a key material in road construction, has specific properties essential for performance and durability. This section explores the composition of bitumen, its desirable properties, and laboratory tests performed to assess its suitability for different applications.

Detailed

Properties and Tests of Bitumen

Bitumen is a viscoelastic and thermoplastic material that is derived from the distillation of crude oil. It is primarily used as a binding agent for aggregates in flexible pavement structures. The effectiveness and longevity of bituminous pavements are largely determined by the physical and chemical properties of bitumen.

9.1 Origin and Composition of Bitumen

Bitumen is obtained from crude oil through fractional distillation, forming the heaviest fraction leftover after lighter fuels are removed.

9.1.1 Chemical Composition

Bitumen is composed of hydrocarbons and contains:

- Asphaltenes (stiffness)

- Resins (adhesion and ductility)

- Aromatics (flow characteristics)

- Saturates (affect aging)

9.2 Desirable Properties for Pavements

Key properties necessary for quality bitumen include:

1. Adhesion: Must bond well with aggregates.

2. Viscosity: Should be appropriate for mixing and provide stiffness.

3. Ductility: Ability to deform without cracking.

4. Durability: Resistance to wear and aging.

5. Temperature Susceptibility: Minimal change in stiffness with temperature variations.

6. Resistance to Water: Should maintain bond in wet conditions.

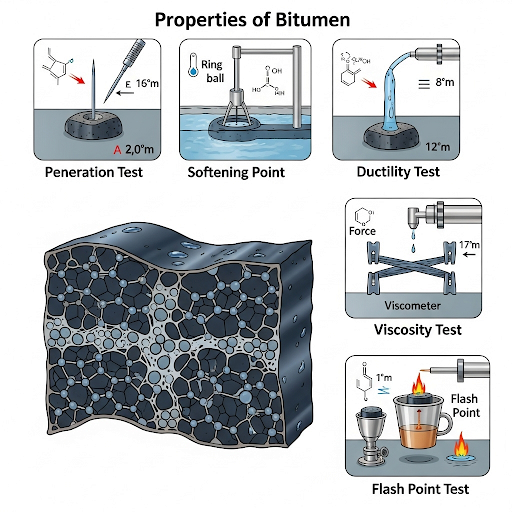

9.3 Tests on Bitumen

Standardized laboratory tests help assess these properties:

- Penetration Test (IS: 1203): Evaluates softness/hardness via needle penetration.

- Softening Point Test (IS: 1205): Determines softening temperature.

- Ductility Test (IS: 1208): Measures elongation before breakage.

- Viscosity Test (IS: 1206): Examines flow characteristics.

- Flash/Fire Point Test (IS: 1209): Determines ignition temperatures.

- Specific Gravity Test (IS: 1202): Measures density.

- Water Content Test (IS: 1211): Analyzes moisture levels.

- Loss on Heating Test (IS: 1212): Evaluates volatility.

- Solubility Test (IS: 1216): Measures purity of bitumen.

- Elastic Recovery Test: Assesses recovery after deformation.

9.4 Grading of Bitumen

Bitumen is classified by:

- Penetration Grade (e.g., 80/100)

- Viscosity Grade (e.g., VG-10)

9.5 Modified Bitumen and Testing

Modified bitumen enhances performance using additives. Common types include Polymer Modified and Crumb Rubber Modified bitumen, which require specific tests.

9.6 Field Quality Control

Quality verification in the field includes visual checks and lab testing to ensure performance standards.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Bitumen

Chapter 1 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bitumen, a viscoelastic and thermoplastic material derived from the distillation

of crude petroleum, is one of the most crucial binding agents used in road

construction. It is primarily utilized in flexible pavement structures as a binder

for aggregates. The performance and durability of a bituminous pavement

depend significantly on the physical and chemical properties of bitumen. This

chapter explores the essential characteristics of bitumen, their significance in

pavement design and construction, and the various laboratory tests that are

conducted to evaluate its suitability.

Detailed Explanation

Bitumen is a material that comes from oil processing and is important for building roads, especially flexible ones. It acts like glue, holding together the stones and other materials in the pavement. The way pavement behaves over time depends on the properties of the bitumen used, so it is crucial to understand these characteristics. This section discusses what makes bitumen special and how it is tested to ensure it will work effectively in different conditions.

Examples & Analogies

Think of bitumen as the icing on a cake, where the cake represents the road's structure. Just like icing holds the cake layers together and adds flavor, bitumen binds the materials in the road, ensuring it stays together and performs well under traffic and weather.

Origin and Composition of Bitumen

Chapter 2 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bitumen is produced from the fractional distillation of crude oil in refineries. It

is the heaviest fraction left behind after the removal of lighter fuels like gasoline,

diesel, and kerosene.

Detailed Explanation

Bitumen is made during the process of refining crude oil. When crude oil is heated, it separates into different components based on their boiling points, much like how different ingredients are separated when cooking. The heaviest part that is left after lighter products such as gasoline is what we refer to as bitumen, which is crucial in road making.

Examples & Analogies

Imagine making a soup and skimming off the lighter foam at the top; the thick part that remains at the bottom is similar to how bitumen is obtained from oil. Just as the thick part gives the soup its rich consistency, bitumen provides strength and durability to roads.

Chemical Composition of Bitumen

Chapter 3 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bitumen is a complex mixture of hydrocarbons containing:

• Asphaltenes: High molecular weight compounds that contribute to the stiffness.

• Resins: Contribute to adhesion and ductility.

• Aromatics: Contribute to flow characteristics.

• Saturates: Paraffinic hydrocarbons that influence aging.

Detailed Explanation

The composition of bitumen includes several types of molecules that each serve different purposes. Asphaltenes are responsible for making bitumen hard and stiff, while resins help it stick to surfaces and allow it to stretch without breaking. Aromatics make it flow better when heated, and saturates help control how bitumen ages over time. Understanding these components helps engineers choose the right type of bitumen for specific applications.

Examples & Analogies

Think of bitumen like a recipe for cookies where each ingredient plays a vital role—flour for structure (asphaltenes), sugar for sweetness and binding (resins), butter for smoothness and flow (aromatics), and eggs for richness and stability (saturates). Just as choosing the right balance of ingredients leads to delicious cookies, having the right balance of components in bitumen leads to strong and durable pavements.

Desirable Properties of Bitumen for Pavements

Chapter 4 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A good quality bitumen should exhibit the following properties:

9.2.1 Adhesion

Bitumen should adhere well to aggregates and maintain that adhesion in the presence of water.

9.2.2 Viscosity

It should have suitable viscosity to facilitate pumping and mixing at high

temperatures and to provide adequate stiffness at service temperatures.

9.2.3 Ductility

Bitumen must be ductile enough to accommodate thermal movements and minor

deformations in pavement without cracking.

9.2.4 Durability

It should resist weathering, oxidation, and aging caused by UV rays and atmo-

spheric conditions.

9.2.5 Temperature Susceptibility

It should exhibit minimal variation in stiffness with changes in temperature.

9.2.6 Resistance to Water

Bitumen should be hydrophobic in nature and must maintain bonding with

aggregates in wet conditions.

Detailed Explanation

For bitumen to be effective in pavement construction, it must possess certain essential properties. It needs to stick well to the aggregates used in the pavement, even when wet (adhesion). It should also flow well under heat but become firm again when cooled (viscosity). It needs to be flexible (ductility) to withstand expansion and contraction due to temperature changes without cracking. Durability is key for resisting damage from the weather and aging. Additionally, its performance should not change much with temperature shifts (temperature susceptibility), and it should repel water while maintaining its grip on the aggregates (resistance to water).

Examples & Analogies

Consider a good winter coat designed for cold climates: it needs to keep you warm (durability), fit snugly without being too tight (ductility), allow you to move freely (viscosity), and not let moisture in (resistance to water). Just like that coat, bitumen must exhibit the right properties to ensure that roads are safe and long-lasting under various conditions.

Tests on Bitumen

Chapter 5 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Various standardized laboratory tests are conducted to evaluate the properties

of bitumen. These tests help ensure that the material is suitable for specific

climatic and loading conditions.

Detailed Explanation

To make sure bitumen meets necessary standards, it undergoes various tests in a lab setting. These tests analyze different properties such as hardness, softness, temperature handling, and how well it can stretch before breaking. Understanding the outcomes of these tests is essential for determining if the bitumen is appropriate for the climate and types of traffic it will face once applied.

Examples & Analogies

Just like cars undergo safety and performance tests before being sold to ensure they can handle different driving conditions, bitumen is tested to guarantee that it can perform well under various environmental and mechanical stressors when used in pavement construction.

Grading of Bitumen

Chapter 6 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Based on penetration and viscosity tests, bitumen is classified into various grades:

Penetration Grade Examples:

• 80/100

• 60/70

• 30/40 (The first number is the minimum penetration, the second is the maximum.)

Viscosity Grade Examples:

• VG-10, VG-20, VG-30, VG-40 (The higher the number, the more viscous the bitumen.)

Detailed Explanation

Bitumen is categorized into different grades by conducting penetration and viscosity tests. For the penetration test, the results show how far a standard needle can penetrate the bitumen, defining the softness level. The viscosity grades indicate how thick or thin the bitumen is, with higher numbers representing thicker varieties. This grading helps engineers choose the appropriate type of bitumen for specific paving needs, ensuring the best performance under expected usage.

Examples & Analogies

Think of this grading system like different types of syrup. Some syrups are thin and runny (like lower viscosity bitumen suits warmer climates), while others are thick and sticky (higher viscosity bitumen works better in colder regions). Just as you’d pick the right syrup for your pancakes based on how you like them, engineers select bitumen grades based on the specific demands of their pavement projects.

Modified Bitumen and Testing

Chapter 7 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Modified bitumen is bitumen blended with polymers, rubber, or other materials

to improve performance.

Common Types:

• Polymer Modified Bitumen (PMB)

• Crumb Rubber Modified Bitumen (CRMB)

Tests for Modified Bitumen:

• Elastic recovery

• Softening point

• Penetration

• Storage stability

Detailed Explanation

Modified bitumen is created by mixing the original bitumen with other substances such as polymers or rubber. This modification enhances its properties, making it better suited for certain applications, particularly in more demanding conditions. Tests are conducted on modified bitumen to determine how well it returns to its original shape after deformation (elastic recovery), its softening characteristics, its penetration level, and its ability to remain stable during storage. These assessments ensure that modified bitumen performs reliably on the roads.

Examples & Analogies

Imagine upgrading a smartphone with new software to improve its performance. Modified bitumen acts similarly; just as the new software enhances the phone's capabilities, adding materials like polymers or rubber enhances the strength and durability of bitumen, making it more effective in various weather conditions and heavier traffic.

Field Quality Control of Bitumen

Chapter 8 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In the field, it is essential to verify the quality of bitumen delivered to the site

through:

• Visual inspection (absence of foam or water)

• Temperature checks before application

• Sampling and lab testing for penetration and viscosity

Detailed Explanation

Once bitumen is delivered to a construction site, it's crucial to confirm its quality before use. This involves visually inspecting the bitumen to ensure there are no impurities such as water or foam, checking the temperature to make sure it's suitable for application, and taking samples for laboratory testing to measure penetration and viscosity. These steps are vital for maintaining high pavement quality and ensuring that the bitumen will perform as expected under traffic.

Examples & Analogies

Think of this quality control as making sure the ingredients for your recipe are fresh and correctly prepared before you start cooking. Just like checking that your eggs are not expired and your flour is not lumpy is important for baking, verifying the quality of bitumen ensures that the final pavement will be smooth and durable.

Key Concepts

-

Bitumen: A thermoplastic binding material used in road construction.

-

Adhesion: The property of bitumen to stick effectively to aggregates.

-

Viscosity: The flow characteristics of bitumen critical for mixing and application.

-

Ductility: Ability of bitumen to undergo deformation without cracking.

-

Penetration Test: A method to evaluate the hardness or softness of bitumen.

Examples & Applications

In flexible pavements, bitumen acts as the glue binding aggregates, similar to how glue holds paper together.

The penetration test's higher values indicate softer bitumen, which is favorable in warmer climates.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To lay down roads, we need to see, Bitumen's grip is like glue, you see!

Stories

Imagine building a road with a glue that holds tightly even when wet; that's bitumen for you, ensuring the hug is never let go!

Memory Tools

Remember A.R.A.S. for bitumen components: Asphaltenes, Resins, Aromatics, Saturates.

Acronyms

AVD helps you recall bitumen's vital properties

Adhesion

Viscosity

Ductility.

Flash Cards

Glossary

- Asphaltenes

High molecular weight compounds in bitumen contributing to stiffness.

- Resins

Compounds that provide adhesion and ductility in bitumen.

- Ductility

The ability of bitumen to deform without cracking.

- Viscosity

A measure of a liquid's resistance to flow.

- Penetration Test

A test that measures the hardness or softness of bitumen.

- Softening Point

The temperature at which bitumen changes from solid to a viscous liquid.

- Ductility Test

A test measuring the elongation of bitumen before breaking.

- Specific Gravity

A measure of the density of bitumen relative to water.

Reference links

Supplementary resources to enhance your learning experience.