Softening Point Test (Ring and Ball Method) (IS: 1205)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Softening Point Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re going to learn about the Softening Point Test, also known as the Ring and Ball Method. Can someone tell me why it’s important to know the softening point of bitumen?

Is it to know how well it behaves in hot weather?

Exactly! The softening point helps us understand how bitumen will perform under high temperatures. Now, let's look at the apparatus we use. We have the ring and ball apparatus, a heating bath, and a thermometer. Can anyone explain what we do with these?

We heat the bitumen in the rings with the balls on top, right?

That's correct! We heat it until the balls touch the base plate, and we record that temperature. This is crucial because it influences how we design pavements. Remember, the acronym HITS: Heating, Indicators, Test method, and Significance.

What does HITS stand for again?

HITS stands for Heating, Indicators, Test method, and Significance. It helps you recall the steps and importance of the Softening Point Test. Let's move to the next session where we discuss how to interpret the results.

Interpreting Results of the Softening Point Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we've covered how to conduct the Softening Point Test, let's discuss the results. What do you think a higher softening point indicates?

Does it mean the bitumen is better for hot climates?

Correct! A higher softening point implies it can withstand higher temperatures without deforming. Conversely, what might a low softening point suggest?

It could mean it deforms under heat?

Exactly! Low softening points can lead to deformation which is essential to consider in pavement materials. Can anyone relate this to real-world applications in road construction?

If we’re in a hot region, we would need bitumen with a higher softening point to avoid issues.

Great connection! Always remember that the performance of pavement materials can significantly impact road quality and longevity. Let’s wrap this session up. We learned that a higher softening point often correlates with better performance in high-temperature conditions.

Practical Applications of the Softening Point Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss the practical applications of the Softening Point Test. Why is this test critical for civil engineers?

It helps us choose the right type of bitumen for different projects.

Absolutely! It plays a role in design decisions. Can anyone provide an example where this test might be particularly useful?

When constructing roads in areas with high temperatures, like deserts!

Correct! In such cases, bitumen with a higher softening point will prevent issues like rutting. Remember the mnemonic PAVE: Performance, Application, Variation, and Environment. It's crucial for understanding these points.

What was PAVE again?

PAVE represents Performance, Application, Variation, and Environment. It helps you remember factors affecting the choice of bitumen regarding softening points. We’ll conclude today’s session here, emphasizing how essential this test is in ensuring the quality and longevity of pavement structures.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section outlines the Softening Point Test (Ring and Ball Method) used to measure the temperature at which bitumen begins to soften. The test involves heating bitumen in brass rings, with steel balls placed on top, and records the temperature at which the balls touch the base plate. Understanding the softening point helps assess the material's thermal susceptibility and behavior under service conditions.

Detailed

Softening Point Test (Ring and Ball Method) (IS: 1205)

The Softening Point Test is designed to evaluate the temperature at which bitumen transitions from a solid to a softer plastic state, marking its thermal behavior in various applications, particularly in road construction.

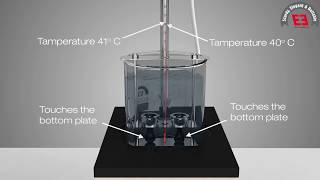

Apparatus Required

- Ring and Ball apparatus: special equipment to hold the bitumen sample and test it under controlled temperature conditions.

- Heating bath: to heat the bitumen sample at a consistent rate.

- Thermometer: to accurately measure the temperature during the test.

Test Method

- Preparation: Bitumen is heated and poured into brass rings.

- Placement: Steel balls are positioned on the top of the bitumen in the rings.

- Observation: As the temperature increases, the tester monitors the moment the balls descend and touch the base plate beneath the rings. The temperature at this precise moment is recorded.

Significance

The softening point is essential for assessing the temperature susceptibility of bitumen. It provides insights into the material's expected behavior at elevated temperatures, which is critical in evaluating its suitability for various pavement applications. A higher softening point generally indicates better performance in hot climates, whereas a lower softening point may suggest increased risk of deformation.

Understanding the softening point is key for engineers and material scientists when selecting the appropriate type of bitumen for specific environmental conditions and operational requirements.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Purpose of the Test

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Determines the temperature at which bitumen softens under specific conditions.

Detailed Explanation

The purpose of the softening point test is to find the temperature at which bitumen transitions from a solid state to a more fluid and workable state. This is essential to understand how the material behaves in different environmental conditions, particularly during high temperatures.

Examples & Analogies

Think of ice cream on a hot day. Just like ice cream starts to melt as it gets warmer, bitumen also softens when exposed to heat. Knowing the softening point helps engineers predict how bitumen will perform in hot weather.

Apparatus Required

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Ring and Ball apparatus

• Heating bath

• Thermometer

Detailed Explanation

For this test, specific equipment is needed to accurately determine the softening point of bitumen. The Ring and Ball apparatus consists of brass rings that hold the bitumen, while steel balls placed on top help measure when the bitumen has melted enough to allow the balls to touch the base plate. A heating bath is used to gradually increase the temperature, and a thermometer monitors the temperature.

Examples & Analogies

Imagine you're trying to figure out when chocolate melts in a bain-marie (double boiler). You need the right bowl, heat, and a thermometer to ensure you reach the correct melting point without burning it.

Test Methodology

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Bitumen is heated and placed in brass rings.

• Steel balls are placed on top.

• Temperature is recorded when balls touch the base plate.

Detailed Explanation

The test begins with heating the bitumen until it becomes soft enough to flow. This softened bitumen is then placed into the brass rings, and steel balls are positioned on top. As the temperature continues to rise, the bitumen softens until the weight of the balls causes them to drop and touch the base plate. The temperature at which this occurs is recorded as the softening point.

Examples & Analogies

Imagine a playground swing: if the swing is too high (like solid bitumen) it won't swing down easily. But as it sinks lower (becomes soft), eventually it reaches a point where it can swing down easily. The lower the swing gets (increased temperature), the more it moves. The point where it moves is like the softening point of bitumen.

Significance of the Test

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Indicates temperature susceptibility.

• Used to assess behavior at high service temperatures.

Detailed Explanation

Understanding the softening point of bitumen is crucial for engineers and builders. It indicates how the bitumen will perform in high temperature conditions, which is particularly important for areas that experience hot climates. If the softening point is too low, the bitumen may not hold its shape and could lead to pavement deformation.

Examples & Analogies

Think of a rubber band: if it’s too warm, it stretches and loses its form. Similarly, if bitumen softens too much in hot weather, it may not provide the support needed for a properly constructed road, resulting in cracks and potholes.

Key Concepts

-

Softening Point: The temperature at which bitumen starts to soften.

-

Testing Method: Ring and Ball methodology to determine softening point.

-

Thermal Susceptibility: Understanding how temperature affects bitumen's performance.

Examples & Applications

Example 1: In a hot climate region, engineers would prefer a bitumen with a higher softening point to prevent deformation.

Example 2: For a road constructed in a cold environment, bitumen with a lower softening point may be suitable.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When bitumen's hot, it gets a touchy slot, the rings will rise, and the balls will surprise!

Stories

Imagine a hot summer day when the pavement heats up—like a melting chocolate bar. The softening point is when the roads begin to feel the heat—this is when the balls drop!

Memory Tools

Remember the acronym HITS: Heating, Indicators, Test method, and Significance—focus on what's being observed, measured, and noted.

Acronyms

Use PAVE to remember

Performance

Application

Variation

and Environment—important factors in selecting bitumen.

Flash Cards

Glossary

- Softening Point

The temperature at which bitumen loses its hardness and begins to soften under specified conditions.

- Ring and Ball Apparatus

Specialized equipment used to perform the softening point test of bitumen.

- Temperature Susceptibility

The degree to which the physical properties of a material change with temperature.

Reference links

Supplementary resources to enhance your learning experience.