Air Void Content in Mix

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Air Void Content

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to learn about air void content and its significance in bituminous mixes. Can anyone tell me what air void content refers to?

Is it the amount of air that gets trapped inside the asphalt mix?

Exactly! Air void content refers to the tiny air spaces present in the mix that are not occupied by the binder or aggregates. Why do you think this might be important for durability?

I guess if there’s too much air, it could let moisture and oxygen in, right?

Yes, that's spot on! Excessive air voids can indeed allow oxygen and moisture to penetrate more easily, leading to faster deterioration of the pavement. Let's remember -- 'Less Air = More Durability'!

Effects of Excessive Air Voids

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand what air voids are, let’s delve into what happens when there are excessive air voids in the mix. Can anyone think of possible issues it might cause?

Maybe it can lead to oxidation since the air gets in?

Exactly! Increased exposure to oxygen leads to oxidation, which thickens the binder and makes the pavement less flexible. Besides that, moisture can also lead to stripping of the binder from aggregates. Does anyone remember a term for that?

Stripping! It’s when the binder loses adhesion to the aggregates, right?

That's correct! This stripping can cause significant structural issues and thus affect durability negatively. Let's summarize: excessive air voids can lead to oxidation and stripping, impacting durability.

Best Practices in Managing Air Voids

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To ensure optimal pavement performance, we need to manage air void levels effectively. What practices do you think could help with this?

Maybe using the right mix design and compaction?

Absolutely! Using the right mix design ensures the right ratio of materials, while adequate compaction can minimize air voids. Remember, compacting thoroughly can result in fewer air voids. Can someone repeat our takeaway?

'Optimal air voids lead to improved durability!'

Great job! This understanding is vital in designing durable pavements.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Air void content is a critical factor in the durability of bituminous materials. Excessive air voids can compromise the structural integrity of the pavement by allowing easier access for oxygen and moisture, leading to accelerated deterioration and potential failure. Understanding the balance of air voids is essential for ensuring long-lasting pavement performance.

Detailed

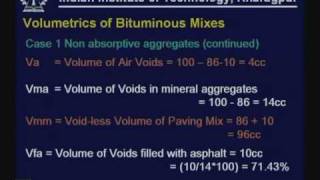

Air Void Content in Mix

Air void content refers to the small spaces within a bituminous mix that are not filled with the binder or aggregates. This section emphasizes that the amount of air voids in a bitumen mix holds substantial importance for its durability. Excessive air voids can facilitate the penetration of oxygen and moisture into the mix, which can accelerate the chemical and physical degradation processes such as oxidation and moisture-induced stripping. Consequently, maintaining an optimal air void level is crucial for achieving a durable pavement system that can withstand various environmental stresses and traffic loads.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Impact of Air Void Content

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Air Void Content in Mix:

– Excessive air voids allow oxygen and moisture to penetrate easily.

Detailed Explanation

Air void content refers to the amount of air that is trapped in a mix of bituminous materials, such as asphalt. If there are too many air voids, it creates spaces in the material. These spaces can allow outside elements like oxygen and moisture to enter the pavement. When moisture penetrates, it can lead to damage over time, such as weakening the bond between aggregates and the binder, which is crucial for the integrity of the pavement.

Examples & Analogies

Think of air voids like bubbles in a sponge. If the sponge has too many large bubbles, it can soak up too much water, making it heavy and ineffective for cleaning. Similarly, excessive air voids in asphalt can make the pavement 'soak up' moisture, leading to quicker deterioration.

Consequences of Excessive Air Voids

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Implications of Excessive Air Voids:

– Increased risk of structural failure due to moisture infiltration.

– Potential for rapid wear and premature maintenance needs.

Detailed Explanation

Excessive air voids can cause significant issues in structural integrity. As moisture infiltrates through these voids, it can weaken the mix and lead to cracking or even complete failure of the pavement. Rapid deterioration means that maintenance will need to be conducted more frequently, increasing costs and resources needed for upkeep. This effect makes it critical to control air void levels during the mixture design stage.

Examples & Analogies

Imagine constructing a house with poor insulation that allows water and cold air to seep in through gaps. Over time, the structure weakens, and repairing the damage becomes more complicated and costly. The same principle applies to bituminous pavements with excessive air voids, leading to the necessity for more frequent repairs.

Key Concepts

-

Air Void Content: The spaces within a mix not filled with other materials, affecting durability.

-

Oxidation: A chemical deterioration process that hardens bitumen.

-

Stripping: A failure mode where binder loses adhesion to aggregates due to moisture.

Examples & Applications

A well-compacted asphalt mix will typically have between 3-8% air void content, resulting in better durability compared to a poorly compacted mix with 15% air voids.

In regions with heavy rainfall, a mix with high air void content may suffer more from moisture-related stripping.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

More air means wear, less air means care!

Stories

Imagine a sponge (the asphalt) in the rain (moisture). If it has too many holes (air voids), it soaks in water and becomes weak. Keep it less permeable for strength!

Memory Tools

A for Air Void, O for Oxidation, S for Stripping – remember to keep air less for optimal mix!

Acronyms

A.V.A (Air Void Awareness) - Always consider the balance of air for durability!

Flash Cards

Glossary

- Air Void Content

The amount of air present within a bituminous mix that is not occupied by binder or aggregates.

- Oxidation

A chemical reaction that occurs when bitumen interacts with atmospheric oxygen, leading to changes in its properties.

- Stripping

The loss of adhesion between the binder and the aggregates due to moisture intrusion.

Reference links

Supplementary resources to enhance your learning experience.