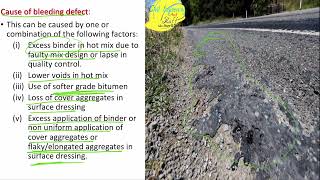

Bleeding

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Bleeding

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss 'bleeding' in pavement materials. Can anyone tell me what they think bleeding refers to in this context?

Is it about the binder getting too hot and leaking out?

That's quite close! Bleeding indeed happens when low viscosity binder rises to the surface. It often occurs in hot weather conditions and is due to the thermal expansion of the binder.

Does that mean the surface becomes slippery?

Exactly! This slick surface can pose a significant safety risk by reducing the friction necessary for vehicles. That's why understanding this phenomenon is critical for pavement performance.

Effects of Bleeding on Pavement Performance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand what bleeding means, let’s discuss its effects. How does bleeding impact the performance of pavements?

It sounds dangerous because if it's too slippery, vehicles might skid.

Correct! Bleeding reduces skid resistance, which can lead to accidents. It can also accelerate the deterioration of the pavement as the binder wears off more quickly under traffic.

Are there ways to prevent this?

Yes! Using higher viscosity binders, or modifying the binder composition with polymers can help prevent bleeding. It's important for engineers to choose materials wisely.

Detecting and Addressing Bleeding

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Identifying bleeding early is crucial. What are some signs that indicate bleeding?

A shiny appearance on the road surface?

Yes! A glossy look is a clear indicator. Additionally, surface texture might be compromised as well. What could we do if we detect bleeding?

Maybe we can apply some coarse material on the surface?

Great suggestion! Applying a layer of coarse aggregate can help improve the skid resistance. Regular maintenance is key in managing pavement health.

Case Studies and Real-World Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's look at some case studies. What have we seen in regions that are hot and experience high traffic volumes?

I think they often report more bleeding issues.

Exactly! Areas with high temperatures and traffic loads tend to experience serious bleeding problems. Understanding regional factors helps in better planning of pavement design.

So, should engineers adjust their designs based on local conditions?

Absolutely. The adaptability of materials and designs based on environmental conditions is essential for successful pavement engineering.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses bleeding, a critical surface defect of bituminous materials characterized by the upward movement of binder to the pavement surface, often occurring in hot weather. The implications of bleeding include reduced skid resistance and potential damage to traffic safety.

Detailed

Detailed Summary

Bleeding is a crucial aspect in the performance of bituminous pavements that occurs when low viscosity binders rise to the surface due to high temperatures and traffic loading. This phenomenon results in a layer of binder that appears shiny and significantly alters the texture of the pavement surface. The implications of bleeding can lead to reduced friction, increasing the risk of skidding for vehicles. The section highlights the causes, effects, and potential remedies for bleeding, emphasizing the necessity for designers and engineers to understand this behavior in order to ensure pavement longevity and safety.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Bleeding

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bleeding: Caused by low viscosity binder in hot weather.

Detailed Explanation

Bleeding is a phenomenon that occurs in bituminous pavements, primarily when the temperature is high. In this situation, the binder (the sticky substance that holds the aggregate particles together) can become too liquid due to the heat. As a result, it can rise to the surface of the pavement, creating a layer of excess binder. This condition is often observed in hot weather when the pavement heats up significantly.

Examples & Analogies

Imagine pouring syrup over a stack of pancakes. If the syrup is warm and runny, it may pool on top of the pancakes rather than soaking in. Similarly, when a pavement’s binder is too fluid in the heat, it can bleed to the surface instead of staying where it’s needed among the aggregates.

Implications of Bleeding

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

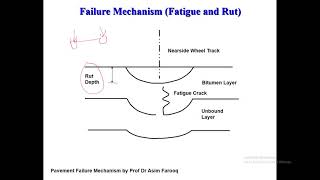

Bleeding can lead to several issues, including reduced skid resistance and premature pavement failure.

Detailed Explanation

When bleeding occurs, the excess binder on the surface can create a slippery film. This lowers the friction between the pavement and vehicle tires, potentially leading to hazardous driving conditions, especially in wet weather. Moreover, over time, if bleeding continues without intervention, it can contribute to the overall deterioration of the pavement, leading to cracks or even structural failures.

Examples & Analogies

Consider how ice on a road makes it slippery and treacherous to drive on. Just as ice reduces traction and increases the risk of accidents, bleeding can create a thin layer of slippery binder that increases the risk of vehicle skidding.

Prevention of Bleeding

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

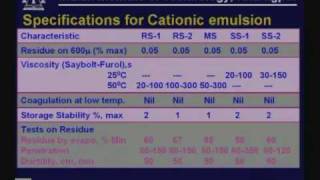

To prevent bleeding, using the right grade of binder and controlling the mix design are critical.

Detailed Explanation

Preventing bleeding involves selecting the appropriate type of binder that has a higher viscosity at elevated temperatures, which helps it maintain its integrity and prevents it from flowing to the surface. Additionally, proper mix design that includes adequate aggregate gradation and binder content can reduce the likelihood of excess binder rising up as the pavement heats. This careful planning during the initial stages of road construction is essential for long-lasting pavement durability.

Examples & Analogies

Think about making a smoothie. If you use too much liquid, it may turn out too runny and spill all over the place instead of being thick and creamy. In the same way, using the right amount and type of binder can help ensure the pavement is sturdy and avoids the issue of bleeding.

Key Concepts

-

Bleeding: The rise of low viscosity binder to the surface of asphalt due to heat.

-

Impact on Safety: Reduces skid resistance leading to potential accidents.

-

Prevention Techniques: Use of high viscosity binders and regular maintenance.

Examples & Applications

In hot climates, asphalt roads often experience bleeding where the binder rises to the top, leading to slippery surfaces.

An example of a preventative measure includes using polymer-modified asphalt to mitigate bleeding.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Bleeding asphalt makes it slick, cars might slide, that's not a trick.

Stories

Imagine a hot day when a pavement looks shiny. That's the binder trying to escape to the surface, making it less safe for cars, so always be cautious!

Memory Tools

Bleed: Binder Lifts Easily & Endangers Drivers.

Acronyms

B.L.E.E.D. - Binder Lifts due to Excessive Environmental Degradation.

Flash Cards

Glossary

- Bleeding

The phenomenon where low viscosity binder rises to the pavement surface under high temperatures.

- Skid Resistance

The ability of a surface to provide the required friction to prevent slipping.

- Low Viscosity Binder

A type of binder that is more fluid and susceptible to elevation under thermal conditions.

Reference links

Supplementary resources to enhance your learning experience.