Enhancing the Durability of Bituminous Materials

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Material Modification Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore how material modifications can enhance the durability of bituminous materials. Can anyone explain what anti-stripping agents do?

They improve the adhesion of binder to aggregates, right?

Exactly! Anti-stripping agents like amines and hydrated lime help combat moisture damage. Remember the acronym AHA: Anti-stripping agents Enhance Adhesion!

What about polymer-modified bitumen? How does that help?

Good question! Polymer-modified bitumen increases elasticity and resistance to oxidation. This means it performs better under temperature changes—think of it as flexible yet strong material!

So how does crumb rubber come into play?

Crumb rubber enhances fatigue life and temperature resistance. So, when it’s hot or cold, CRMB keeps the pavement strong! Remember: Rubber revives road resilience!

In summary, modified materials like anti-stripping agents, PMB, and CRMB are critical for enhancing durability.

Improved Mix Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

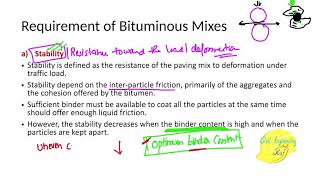

Now let's talk about how mix design impacts the durability of bituminous materials. Who can share what optimum binder content means?

It's about finding the right amount of binder to prevent aging, right?

Spot on! Balance is key because too much or too little can cause issues. Think of it like a cake – too much flour or sugar won't give the desired taste!

What role does compaction play then?

Proper compaction is crucial as it reduces air voids. Fewer air voids mean less permeability, leading to a stronger pavement! Remember: Tighten up for better durability!

How about gradation control?

Great point! Controlling aggregate gradation ensures better interlock and reduces binder film thickness. So better gradation gives a compact structure.

To recap, a well-designed mix with the right binder content, proper compaction, and controlled gradation greatly enhances durability.

Drainage Improvement Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's move on to drainage improvements. Why is drainage crucial for bituminous materials?

To prevent water accumulation that can weaken the material?

Exactly! Effective surface and subsurface drainage systems are essential. They keep water away from the pavement structure, minimizing damage.

What happens if the drainage design fails?

If drainage fails, it can lead to moisture intrusion, causing stripping and deterioration. That's why we're targeting proactive drainage solutions. Remember the phrase: 'Drainage saves the day!'

Can you summarize the key aspects of drainage?

In summary, effective drainage is vital for preventing moisture-related damage, ensuring our pavements last longer. Clear drainage means clear pathways!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Enhancing the durability of bituminous materials involves modifying the materials themselves, improving mix design, and ensuring effective drainage. Key approaches include using anti-stripping agents, polymer modification, optimizing binder content, and designing proper drainage systems.

Detailed

Enhancing the Durability of Bituminous Materials

This section outlines critical strategies to improve the durability of bituminous materials, which are vital for the longevity and performance of flexible pavements. Key methods include:

1. Material Modification

- Anti-Stripping Agents: The incorporation of amines and hydrated lime significantly enhances binder adhesion to aggregates, combating moisture-related damage.

- Polymer Modified Bitumen (PMB): This modification increases elasticity and resistance to oxidation, improving the material's overall longevity.

- Crumb Rubber Modified Bitumen (CRMB): Using recycled rubber enhances the bitumen's fatigue life and thermal resistance, addressing performance in varied temperature conditions.

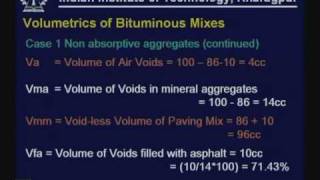

2. Improved Mix Design

- Optimum Binder Content: Determining the appropriate amount of binder is essential to prevent aging and promote long-term flexibility.

- Proper Compaction: Ensuring that the mix is adequately compacted reduces air voids and permeability, strengthening the pavement structure.

- Gradation Control: By controlling aggregate gradation, better interlock among particles is achieved, leading to reduced binder film thickness and improved overall durability.

3. Drainage Improvement

- Surface and Subsurface Drainage: Designing effective drainage solutions helps prevent water accumulation, which is crucial for minimizing moisture-related failure mechanisms in bituminous materials.

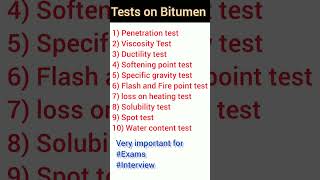

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Material Modification

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

14.4.1 Material Modification

- Use of Anti-Stripping Agents:

- Amines and hydrated lime improve adhesion.

- Polymer Modified Bitumen (PMB):

- Increases elasticity and resistance to oxidation.

- Crumb Rubber Modified Bitumen (CRMB):

- Enhances fatigue life and temperature resistance.

Detailed Explanation

This chunk discusses how modifying materials can enhance the durability of bituminous materials. Anti-stripping agents, such as amines and hydrated lime, help improve the bonding between the bitumen and aggregates, preventing issues like stripping under moisture. Polymer Modified Bitumen (PMB) is created by adding polymers to bitumen, which increases its flexibility and makes it resistant to degradation by oxidation. Crumb Rubber Modified Bitumen (CRMB) incorporates rubber chips into bitumen to enhance its performance, particularly in areas with high traffic loads and temperature variations.

Examples & Analogies

Think of bituminous materials like a simple pair of shoes. By adding special materials (like an anti-stripping agent) to the shoe's sole glue, the shoes can better withstand rain and mud without falling apart. Similarly, just as shoes made from flexible material can bend without cracking, using Polymer Modified Bitumen helps pavements remain flexible under heavy traffic.

Improved Mix Design

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

14.4.2 Improved Mix Design

- Optimum Binder Content:

- Prevents binder aging and ensures long-term flexibility.

- Proper Compaction:

- Reduces air voids and permeability.

- Gradation Control:

- Ensures better interlock and reduced binder film thickness.

Detailed Explanation

This chunk elaborates on how the design of the bituminous mix can significantly impact its durability. 'Optimum Binder Content' refers to using just the right amount of binder in the mix to prevent problems like aging and cracking. 'Proper Compaction' ensures that the mix is dense with fewer air pockets, thus reducing water permeability. 'Gradation Control' involves selecting the right sizes and types of aggregates so they fit together well, creating a stronger bond and thinner layers of binder, which reduces wear and tear.

Examples & Analogies

Imagine making a cake. If you use too much flour (binder) or don’t mix it well (compaction), your cake might crumble easily. However, if you ensure the flour is just right and mix it properly (optimum binder content and proper compaction), you end up with a strong cake that holds its shape over time. Similarly, careful mix design in pavements ensures they are robust and last longer.

Drainage Improvement

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

14.4.3 Drainage Improvement

- **Proper surface and subsurface drainage design prevents water accumulation and reduces moisture-related damage.

Detailed Explanation

This chunk emphasizes the importance of efficient drainage systems in safeguarding the integrity of bituminous materials. Proper drainage minimizes water accumulation on the pavement surface and prevents moisture from infiltrating into the pavement structure. This is crucial since excess moisture can lead to weakening of the bitumen and aggregates, leading to issues like stripping or other forms of deterioration.

Examples & Analogies

Think of a sponge sitting in a puddle of water. If there’s no place for the water to go, the sponge remains soaked and falls apart over time. However, if you create a system to divert the water away (like good drainage design), the sponge remains dry and intact. Similarly, directing water away from road surfaces helps keep pavements strong and durable.

Key Concepts

-

Material Modification: Enhancements like anti-stripping agents and polymer modifications improve durability.

-

Mix Design: Correct binder content, compaction, and aggregate gradation are crucial for sustainability.

-

Drainage: Effective drainage prevents moisture-related damage, extending pavement lifespan.

Examples & Applications

Incorporating 5% hydrated lime can significantly enhance the adhesion of bitumen to aggregates, reducing moisture-related issues.

Using PMB in regions prone to temperature fluctuations can improve flexibility and reduce thermal cracking.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For durable roads, don’t just bind, add anti-stripping, keep moisture behind!

Stories

Imagine a wise old engineer who mixed ingredients just right, ensuring every road was strong and tight, using just enough binder to prevent aging's blight.

Memory Tools

Remember the 'D-M-M' - Drainage, Material Modification, and Mix design to enhance durability!

Acronyms

MICE - Modify, Improve, Compaction, and Ensure drainage for pavement durability.

Flash Cards

Glossary

- AntiStripping Agents

Additives like amines and hydrated lime that improve the adhesion of bitumen to aggregates.

- Polymer Modified Bitumen (PMB)

Bitumen modified with polymers to enhance elasticity and resistance to oxidation.

- Crumb Rubber Modified Bitumen (CRMB)

Bitumen enhanced with crumb rubber to improve fatigue life and temperature resistance.

- Optimum Binder Content

The ideal amount of binder in a mix that prevents aging and ensures long-term flexibility.

- Gradation Control

Managing the distribution of particle sizes in an aggregate mix to ensure optimal performance.

- Drainage Improvement

Techniques designed to manage water away from pavement structures to reduce moisture-related damage.

Reference links

Supplementary resources to enhance your learning experience.