Proper Compaction

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Proper Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll discuss the significance of proper compaction in the performance of bituminous materials. Can someone tell me why compaction is important?

Is it to make sure the pavement is strong and doesn’t break easily?

Exactly! Proper compaction indeed contributes to a stronger pavement. It reduces air voids, which helps prevent moisture intrusion. Remember the acronym 'PAID' for Proper Air voids in the Design.

What happens if there are too many air voids then?

Great question! Too many air voids can allow moisture to enter the pavement, leading to deterioration. This is something we need to avoid.

So, how do we ensure proper compaction?

We will discuss that in detail, focusing on the optimal binder content and gradation control.

Let’s summarize: Proper compaction ensures we have minimal air voids, enhancing durability and performance under environmental changes.

Factors Influencing Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's delve into the factors that influence compaction. Can anyone name one?

The binder content?

Yes! The optimum binder content plays a huge role. It ensures that the mix retains flexibility over time. Remember, the right mix helps avoid aging!

What about the type of aggregates?

Excellent! Gradation control, or the type of aggregates affects how they interlock. A well-graded aggregate structure means better compaction.

Are there other factors?

Certainly! Factors like temperature during compaction and compaction techniques also matter. Let’s remember the term 'GAT' for Gradation, Air voids, and Temperature.

In summary, factors like binder content, gradation, and temperature all play pivotal roles in achieving proper compaction.

Consequences of Improper Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's discuss what happens if we don't achieve proper compaction. Can someone share their thoughts?

I think it would lead to cracks or something, right?

Exactly! Improper compaction can lead to premature cracking and loss of strength due to moisture ingress. It's crucial to avoid this!

Does that mean the pavement will need repairs sooner?

Yes! Repairs can be costly. Think of ‘REPAIR’ - Relying on Effective Pavement Adherence to Improve Resilience. That's why proper compaction is key!

So how can we fix a poorly compacted pavement?

We would need to assess it and possibly do a selective rehabilitation, but prevention through good compaction is always the best approach!

To summarize, inadequate compaction can lead to cracks, increased moisture intrusion, and costly repairs.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the critical role of proper compaction in ensuring bituminous mixes achieve optimal density. Proper compaction minimizes air voids, thereby reducing permeability and preventing premature deterioration due to moisture intrusion and aging.

Detailed

Proper Compaction

Compaction is a vital process in the construction of bituminous pavements that significantly affects their durability and longevity. Proper compaction techniques are aimed at achieving the optimal density of bituminous mixtures, which is crucial for minimizing air voids and permeability. Excessive air voids in a pavement can lead to various issues, including moisture intrusion, which accelerates the deterioration of the pavement through stripping of the binder from aggregates and increases susceptibility to aging.

The effectiveness of proper compaction depends on several factors:

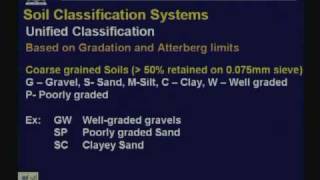

- Optimum Binder Content: The selection of the correct binder content during the mix design process is fundamental. It prevents binder aging and ensures long-term flexibility of the pavement.

- Gradation Control: Ensuring the correct gradation of aggregates contributes to better interlock within the mix. A well-graded mix results in a reduced binder film thickness, reducing the risks of binder stripping and enhancing durability.

Overall, effective compaction leads to substantial improvements in the performance of bituminous pavements under the impacts of environmental conditions and traffic loading.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Proper Compaction

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Proper Compaction:

- Reduces air voids and permeability.

Detailed Explanation

Proper compaction in bituminous materials plays a crucial role in enhancing performance. When the materials are compacted properly, it helps to eliminate air voids within the mixture. Air voids are small pockets of air trapped in the asphalt, which can lead to issues like reduced strength and increased water permeability. By reducing these voids, the compacted material becomes denser and more resilient, leading to a more durable pavement.

Examples & Analogies

Think about a sponge. When it is dry, it has many air pockets, which means it can absorb a lot of water. However, if you press the sponge, you expel the air and it holds less water, allowing it to be used more effectively and last longer in the water. Similarly, proper compaction of bituminous materials removes air pockets, allowing the pavement to withstand heavier traffic and environmental conditions without failing.

Consequences of Poor Compaction

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Improper compaction leads to increased air voids, which can compromise durability.

Detailed Explanation

If compaction is not done correctly, it results in higher air voids in the bituminous mixture. This is problematic because excessive voids can increase permeability, allowing water to infiltrate the pavement structure. Water can then weaken the binder, leading to stripping (where the binder separates from the aggregate) and general deterioration of the pavement. Consequently, poor compaction can lead to reduced lifespan and increased maintenance costs for the pavement.

Examples & Analogies

Imagine trying to build a sandcastle with loose sand. If the sand is not packed tightly, the castle may collapse and wash away easily when waves come in. In contrast, a tightly packed sandcastle holds its shape better against the waves. In the same way, properly compacted asphalt withstands stresses from traffic and weather, while poorly compacted asphalt can fall apart easily.

Achieving Proper Compaction

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

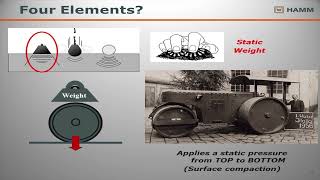

Factors to consider include the right compaction equipment, moisture content, and adequate compaction technique.

Detailed Explanation

To achieve proper compaction of bituminous materials, several factors must be considered. The choice of compaction equipment is critical; it must be suited for the type and thickness of the asphalt layer being laid. Additionally, the moisture content of the mixture is vital since too much moisture can hinder compaction while too little can make it difficult to achieve sufficient density. Lastly, employing the correct compaction technique—such as the timing of rolling after laying the asphalt—ensures that the material is compacted while it is still warm.

Examples & Analogies

Think of baking a cake. If your batter is too wet, the cake might not hold together when baking. If it’s too dry, it won't rise properly. However, if you mix the right consistency and give it the right amount of heat in the oven, you get a beautifully risen cake. In asphalt paving, getting the moisture and compaction techniques just right is similarly essential for producing a strong, lasting pavement.

Key Concepts

-

Proper Compaction: Essential for minimizing air voids and ensuring long-lasting pavements.

-

Optimum Binder Content: The ideal amount of binder ensures flexibility and prevents aging.

-

Gradation Control: Affects how well aggregates interlock and influences mix properties.

-

Air Voids: Excessive air voids can lead to pavement deterioration and moisture ingress.

Examples & Applications

Using a higher percentage of polymer-modified bitumen can enhance the flexibility and longevity of pavement due to improved compaction.

A well-graded aggregate mix leads to a smoother surface and reduces the potential for cracks.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Compaction is key, for pavements you see, to keep voids away, for better display.

Stories

Imagine a builder who skips compaction. The pavement cracks like it's in a fraction. When done right, the road is smooth and strong, lasting through rain, right where it belongs.

Memory Tools

Remember 'PAG' for Proper, Air voids, and Gradation when thinking about compaction.

Acronyms

Use 'PAVE' - Proper Air voids for a Viable Environment to enhance compaction results.

Flash Cards

Glossary

- Compaction

The process of densifying bituminous materials to minimize air voids and enhance durability.

- Air Voids

Spaces within the pavement that can be filled with air, which can lead to degradation if excessive.

- Optimum Binder Content

The ideal amount of binder in a mix that ensures flexibility and resistance to aging.

- Gradation Control

The distribution of particle sizes in aggregate that affects the density and performance of the pavement mix.

Reference links

Supplementary resources to enhance your learning experience.