Durability of Bituminous Materials

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Definition of Durability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re discussing the concept of durability in bituminous materials. Can anyone tell me what 'durability' means?

Isn't durability about how long the material lasts without falling apart?

Exactly! Durability refers to the materials' ability to resist aging, disintegration, and loss of properties over time. Why do you think this is important for pavements?

It affects how often we need to repair roads, right?

Right again! Good durability means fewer repairs and a longer lifespan! We often summarize this with the acronym AAD - Aging, Adhesion, and Degradation. Remember that!

Factors Affecting Durability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about the factors that influence durability. Who can name one?

I think the type of bitumen used matters?

Absolutely! The grade and composition of the bitumen can greatly affect its aging resistance. Higher aromatic content typically leads to better durability. What are some other factors?

Air void content? More air lets in moisture, right?

Correct! High air voids can indeed facilitate moisture penetration, which is detrimental. Let's recap: Bitumen type, air voids, aggregate-binder adhesion, traffic stress, and temperature variations all play vital roles in durability.

Importance of Durability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Why do you think understanding durability is crucial in designing pavements?

It helps us make better materials that don't break down quickly.

Exactly! Better-designed materials lead to less maintenance and longer-lasting pavements. What might be the consequences of ignoring durability in our designs?

I guess it would lead to more road repairs and costs.

That's right! We refer to this as the cost of neglect in material durability. Always remember that understanding durability not only aids in selecting materials but also in budgeting for long-term maintenance.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the concept of durability in bituminous materials, which includes their ability to resist aging, disintegration, and loss of properties under environmental and traffic stress. Key factors influencing durability, such as bitumen grade and composition, air void content, and temperature variations, are highlighted.

Detailed

Durability of Bituminous Materials

Durability is defined as the ability of bituminous materials to resist aging, disintegration, and the loss of essential properties over time when exposed to environmental and traffic loading conditions. This characteristic is critical for ensuring that pavements maintain their performance and longevity, necessitating an understanding of various influencing factors.

Key Factors Affecting Durability:

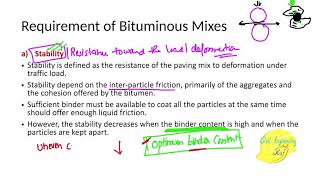

- Bitumen Grade and Composition: Higher aromatic content leads to improved aging resistance, while polymer-modified bitumen significantly enhances durability through better properties.

- Air Void Content in Mix: High air voids can lead to easier penetration of oxygen and moisture, which fosters deterioration.

- Aggregate-Binder Adhesion: Poor adhesion can cause stripping of the binder from aggregates, resulting in further damage.

- Traffic Loading and Stress: Increased stress can induce micro-cracking, allowing moisture to enter and accelerate deterioration.

- Temperature Range of Location: Areas with wide temperature fluctuations are more susceptible to thermal cracking and fatigue due to differential expansion and contraction of materials.

Understanding these factors is essential for designing bituminous materials that withstand the rigors of their environment and maintain their integrity over longer durations.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition and Importance of Durability

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Durability is the ability of bituminous materials to resist aging, disintegration, and loss of essential properties over time under environmental and traffic conditions.

Detailed Explanation

Durability refers to the capacity of bituminous materials—like asphalt used in pavements—to withstand the effects of time, environmental conditions, and mechanical forces from vehicles. It involves resisting not only physical breakdown or disintegration but also the degradation of key properties that are critical for the material's performance. This is crucial because durable materials lead to longer-lasting pavements that require less frequent repairs, ultimately saving costs and ensuring safety.

Examples & Analogies

Imagine a well-made pair of shoes designed to last through years of wear and exposure to the elements. Just as these shoes need to resist wear and remain comfortable over time, bituminous materials must withstand the pressures of weather and traffic to keep roads safe and functional. A shoe that wears out quickly might need replacing after a few months, just like a road that crumbles due to poor durability.

Factors Affecting Durability

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

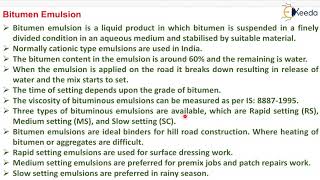

• Bitumen Grade and Composition: Higher aromatic content improves aging resistance.

• Polymer-modified bitumen enhances durability.

• Air Void Content in Mix: Excessive air voids allow oxygen and moisture to penetrate easily.

• Aggregate-Binder Adhesion: Poor adhesion leads to stripping and ravelling.

• Traffic Loading and Stress: Induces micro-cracks that allow moisture ingress.

• Temperature Range of Location: Wide temperature fluctuations increases susceptibility to thermal cracking and fatigue.

Detailed Explanation

Multiple factors affect the durability of bituminous materials. The grade and composition of bitumen play a vital role; for instance, higher aromatic content can enhance the material's ability to resist aging. The use of polymer-modified bitumen can significantly improve overall durability. Additionally, the amount of air voids in the mix matters; too many air voids can lead to oxygen and moisture penetrating the mix, which weakens it. Furthermore, good adhesion between aggregates and the binder is crucial; poor adhesion can cause stripping or ravelling of materials from the surface. Excessive traffic loading introduces stresses that lead to micro-cracking, which, combined with fluctuating temperature ranges, increases the likelihood of serious deterioration.

Examples & Analogies

Think of a sponge soaking up water. If the sponge has bigger holes (similar to having excessive air voids), it absorbs more water and becomes heavy and weak. Similarly, in a pavement, if there are too many air voids, moisture seeps in, weakening its structure. Just as a sponge made of better materials (like higher quality rubber versus a cheap one) lasts longer, so too does asphalt made with high-quality bitumen and careful mix design.

Key Concepts

-

Durability: Key property ensuring longevity and performance of bituminous materials.

-

Factors influencing durability: Bitumen grade, air void content, aggregate-binder adhesion, traffic loading, and temperature range.

Examples & Applications

Use of polymer-modified bitumen to enhance durability in heavily trafficked roads.

Testing different aggregate types for their adhesion properties to optimize mixtures.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If you want your pavement to last, keep the air voids low, and you'll do it fast!

Stories

Imagine a road covered with a magical shield that keeps moisture away. This shield represents the durable properties of bituminous materials.

Memory Tools

Remember 'BATS' - Bitumen, Air, Traffic, and Stress - for durability factors.

Acronyms

Use the word 'DURABLE' to remember key points

D=Durability

U=Under traffic

R=Resistant to moisture

A=Adhesion

B=Bitumen grade

L=Longevity

E=Environment.

Flash Cards

Glossary

- Durability

The ability of bituminous materials to resist aging, disintegration, and loss of essential properties over time under environmental and traffic conditions.

- Bitumen Grade

Classification of bitumen based on its composition, impacting its properties and durability.

- Air Voids

Spaces within a bituminous mix that affect its density and stability and can influence moisture intrusion.

- AggregateBinder Adhesion

The bond between the binder and the aggregate in bituminous mixes; poor adhesion can lead to damage.

- Traffic Loading

The stress imposed on pavements due to vehicular traffic which can induce wear and micro-cracking.

- Temperature Range

The spectrum of temperatures a pavement is exposed to, influencing the occurrence of thermal cracking.

Reference links

Supplementary resources to enhance your learning experience.