Improved Mix Design

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Optimum Binder Content

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's begin by discussing optimum binder content. Why do you think it's crucial for the durability of bituminous materials?

I guess if there’s too little binder, the mix might not hold together well?

Exactly! Insufficient binder can lead to weak mixes that are prone to cracking. Conversely, too much binder can lead to excessive flexibility, making it susceptible to deformation under load. So, finding a balance is vital.

How do we determine the right amount of binder?

Good question! We usually consider the specific type of traffic and environmental conditions. This brings us to the concept of the Superpave mix design method; it incorporates performance-based testing to optimize binder content. Remember the acronym *BERT* - Balance of the Excessive binder and Right content, which helps in remembering this balance.

What happens if the binder doesn’t age well?

Great point! Aging of the binder can lead to hardening, which reduces flexibility. That's why maintaining an optimum binder content is long-term investment in pavement quality.

To summarize, optimum binder content prevents aging and maintains flexibility, ensuring longer-lasting pavements.

Proper Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about proper compaction. Why do you all think compaction is vital in bituminous mix design?

Well, isn’t it about making sure everything fits tightly together?

Yes! Proper compaction helps achieve a dense mix with minimal air voids. These air voids play a significant role because excessive voids allow water and air to penetrate, leading to damage over time, especially during freeze-thaw cycles.

Does this mean we need to use a lot of force when compacting?

Not necessarily a lot of force, but the right amount! Too much force can lead to segregation of materials. So, it’s about using the right method for the material and understanding the desired density. You can remember the phrase *COMPASS* - Consistent Operations Maintain Proper Air Void Structure.

What equipment is used for compaction?

Common tools are rollers and vibratory compactors. They help achieve the appropriate density needed for durability. Let’s summarize: proper compaction reduces voids and permeability, enhancing the pavement’s longevity.

Gradation Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's explore gradation control. Why do you think it is essential in mix design?

Is it about how the different sized aggregates fit together?

Exactly! Proper gradation ensures a well-distributed aggregate size, providing better interlock. This lowers the thickness of the binder film, promoting a stronger mixture.

What happens if the gradation is off?

If gradation is poor, it can lead to weak points in the mix and ultimately lead to ravelling or cracking. A mnemonic for this is *AGREED* – Aggregate Grades Results in Enhanced Durability.

How do we control gradation in practice?

Gradation control often involves careful selection of materials and frequent sampling during production. To wrap up, effective gradation reduces binder thickness and enhances stability.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we explore how improved mix design can significantly enhance the durability of bituminous materials. Key factors include optimizing binder content to maintain flexibility, ensuring proper compaction to minimize air voids, and controlling gradation for better interlock. These elements collectively contribute to a more resilient pavement structure.

Detailed

Improved Mix Design

Improved mix design plays a pivotal role in enhancing the durability and lifespan of bituminous materials, which are crucial in flexible pavement systems. The main strategies include:

- Optimum Binder Content: Ensuring the right amount of binder prevents premature aging and maintains flexibility over time. Too much or too little binder can lead to negative effects on performance.

- Proper Compaction: Effective compaction reduces air voids in the mix, which is vital for decreasing permeability. This reduction helps in limiting moisture intrusion that leads to deterioration.

- Gradation Control: Laying emphasis on the proper gradation of aggregates provides superior interlock within the mixture, leading to reduced binder film thickness. This is essential for maintaining structural integrity and durability.

Overall, these elements are interrelated and contribute to a resilient pavement that withstands various environmental and load-related stresses.

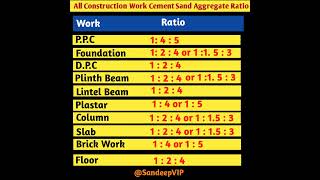

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Optimum Binder Content

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Optimum Binder Content:

- Prevents binder aging and ensures long-term flexibility.

Detailed Explanation

Optimum binder content refers to the ideal amount of binder (the sticky substance that holds everything together) used in a bituminous mix. This optimal quantity helps to maintain the mix's flexibility and prevents it from aging too quickly due to environmental factors, such as temperature changes and UV exposure. When there’s too much binder, it can lead to excessive softness, while too little makes the mix brittle and prone to cracking.

Examples & Analogies

Think of binder content like oil in a cake recipe. If you use just the right amount of oil, the cake will be moist and fluffy. However, too much oil will make it greasy, while too little will result in a dry cake. Similarly, balancing the binder in a bituminous mix ensures it holds well without becoming too stiff or soft.

Proper Compaction

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Proper Compaction:

- Reduces air voids and permeability.

Detailed Explanation

Proper compaction refers to the process of compressing the bituminous mix to eliminate air pockets within it. Reducing air voids is crucial because air pockets can lead to permeability, allowing water to enter the mix. Water infiltration is detrimental as it can promote stripping (loss of the binder from the aggregate) and deterioration over time. Therefore, effective compaction techniques ensure a denser, more durable pavement that can withstand traffic loads and weather conditions.

Examples & Analogies

Imagine packing a suitcase. If you leave lots of air pockets between your clothes, your suitcase will be bulky and may not withstand the jostling during travel. However, if you pack tightly, everything fits better and is less likely to get damaged. A well-compacted pavement behaves similarly, providing strength and durability under pressure.

Gradation Control

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Gradation Control:

- Ensures better interlock and reduced binder film thickness.

Detailed Explanation

Gradation control involves selecting the right mix of aggregate sizes in the bituminous mix. Good gradation ensures that the aggregates fit together well, creating an interlocking structure that enhances strength and stability. When aggregates interlock effectively, less binder is required to fill the spaces between them, which can reduce the overall thickness of the binder film. A thinner film can reduce the risk of deformities and improve the durability of the pavement.

Examples & Analogies

Think of a puzzle. If you use pieces that are too different in size, they won’t fit together well, and the picture will be incomplete. However, if you have a variety of pieces that fit together snugly, you can create a beautiful image with fewer gaps. In the same way, using well-graded aggregates in a pavement ensures it is strong and durable, minimizing the need for excess binder.

Key Concepts

-

Optimum Binder Content: Essential for durability; prevents aging and maintains flexibility.

-

Proper Compaction: Reduces air voids, minimizes permeability, and enhances structural integrity.

-

Gradation Control: Influences the interlock and reduces binder film thickness, promoting strength.

Examples & Applications

Example of optimum binder content: A study found that pavements with an optimum binder content demonstrated a 30% increase in lifespan compared to those with improper content.

Example of gradation control: If the aggregate sizes are too similar, the mix may experience weakness leading to early cracking.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For binder that's just right, the mix will last and not face a plight.

Stories

Imagine a construction site where a team of workers is carefully measuring and mixing asphalt. They discover that using the right amount of binder leads to a strong, flexible pavement capable of handling heavy traffic.

Memory Tools

Remember the term CAB - Compaction, Air voids, and Binder content, a reminder to focus on these three aspects in mix design.

Acronyms

Use *PGC*

Proper Gradation Control leads to better pavement durability.

Flash Cards

Glossary

- Binder Content

The amount of bitumen used in a mix, which can significantly impact the flexibility and durability of the mix.

- Compaction

The process of compressing the asphalt mixture to reduce air voids and enhance the strength of the pavement.

- Gradation

The distribution of particle sizes within a mixture, which affects how well the materials interlock and how much binder is needed.

Reference links

Supplementary resources to enhance your learning experience.