Classification of Sensors

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Classification Based on Measured Quantity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will start by exploring the classification of sensors based on measured quantities. Can anyone tell me what types of measurements we might need in civil engineering?

I think we measure things like displacement, right?

Correct! Displacement sensors are vital. In addition to that, we have strain sensors, load sensors, temperature sensors, vibration sensors, humidity sensors, pressure sensors, inclination sensors, and pore pressure sensors. Remember, we can group these sensors into specific categories. A mnemonic to remember these could be *Distant Stars Light the Path for Humble Pressure Innovations*(representing Displacement, Strain, Load, Temperature, Humidity, Pressure, and Inclination sensors).

What do strain sensors do?

Great question! Strain sensors measure the deformation in materials when subjected to stress. They help in understanding how materials will behave under loads. How about we summarize what each type measures?

Yes! Let's do that!

To summarize: Displacement sensors measure position changes, strain sensors measure deformation, and so on. Each sensor plays a crucial role in monitoring infrastructure health. Have you got all that down?

Classification Based on Working Principle

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's move on to classifications based on working principles. What types of sensors can we find according to how they operate?

There are mechanical and electrical sensors, right?

Yes! Sensors can be categorized as mechanical, electrical, optical, electromagnetic, and ultrasonic. Can you think of examples for each one?

A strain gauge is an example of an electrical sensor!

Exactly! And for mechanical sensors, we might use a diaphragm that moves with pressure changes. It’s essential to understand these principles because they explain how sensors convert physical phenomena into measurable data.

So, if I were to put it all together, can I say that optical sensors use light?

Absolutely correct! Remember, understanding these principles helps us choose the right sensors for specific applications. Let's summarize: we have mechanical, electrical, optical, electromagnetic, and ultrasonic sensors, each suitable for different environments and data types.

Classification Based on Mode of Operation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s discuss the mode of operation. What are the two types of operation we categorize sensors into?

Active and passive sensors?

Exactly! Active sensors require external power, like strain gauges, whereas passive sensors can generate a signal independently, like thermocouples. Why do you think understanding this difference is important?

Maybe because it affects how we install them and their maintenance?

Exactly! Installation and maintenance vary greatly between the two types. Active sensors may need a power source nearby, while passive ones can often be more versatile. Can we summarize? Active sensors need power; passive sensors do not.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, sensors in civil engineering are classified into three main categories: based on the measured quantity (e.g., displacement, strain, load), working principle (e.g., mechanical, electrical, optical), and mode of operation (active vs. passive sensors). Each classification reveals the diversity and applicability of sensors in monitoring structural health and ensuring safety in civil engineering projects.

Detailed

Detailed Summary

The classification of sensors is crucial in understanding their functions and applications in civil engineering. Sensors can be grouped based on three primary criteria:

1. Based on Measured Quantity

Sensors are categorized according to the type of data they measure. Categories include:

- Displacement/Position Sensors: Measure the movement or position of structures.

- Strain Sensors: Detect deformation caused by stress.

- Load/Force Sensors: Measure forces acting on structural components.

- Temperature Sensors: Monitor temperature changes in materials or ambient conditions.

- Vibration/Acceleration Sensors: Capture vibrations to assess structural integrity.

- Humidity Sensors: Track moisture levels in the environment.

- Pressure Sensors: Measure internal or external pressures within structures.

- Inclination Sensors: Determine the tilt angle of structures.

- Pore Pressure Sensors: Measure the pressure of water within soil pores.

2. Based on Working Principle

Sensors can also be distinguished by their operational mechanics, including:

- Mechanical Sensors: Utilize physical movement to provide readings.

- Electrical Sensors: Work on principles of electrical response to measurements.

- Optical Sensors: Use light properties to detect measurements.

- Electromagnetic Sensors: Rely on electromagnetic fields for data collection.

- Ultrasonic Sensors: Employ sound waves to evaluate conditions.

3. Based on Mode of Operation

Sensors are split into two categories based on their requirement for external power:

- Active Sensors: Require an external power source to function, e.g., strain gauges.

- Passive Sensors: Produce their own signals without external energy, e.g., thermocouples.

Understanding these classifications is vital for selecting appropriate sensors for monitoring and ensuring the safety and integrity of civil engineering structures, as each type of sensor serves distinct purposes in various applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Classification by Measured Quantity

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Displacement/Position Sensors

- Strain Sensors

- Load/Force Sensors

- Temperature Sensors

- Vibration/Acceleration Sensors

- Humidity Sensors

- Pressure Sensors

- Inclination Sensors

- Pore Pressure Sensors

Detailed Explanation

In civil engineering, sensors can be classified based on the specific physical quantity they measure. Each type of sensor has a unique function:

- Displacement/Position Sensors: Measure the movement or position of an object.

- Strain Sensors: Detect deformation in materials when they are stressed.

- Load/Force Sensors: Measure the weight or load being applied to structures.

- Temperature Sensors: Monitor temperature changes in materials or environments.

- Vibration/Acceleration Sensors: Measure oscillations or acceleration, often used in structures to detect seismic activity or vibrations.

- Humidity Sensors: Monitor moisture levels in the air or materials.

- Pressure Sensors: Measure the force exerted by gases or liquids.

- Inclination Sensors: Detect tilting or angular displacement.

- Pore Pressure Sensors: Measure the pressure of fluids within soil pores, important for stability assessments in ground engineering.

Examples & Analogies

Think of a sport like basketball where each type of sensor is like a different position on the court. For example, a point guard (displacement sensor) tracks the ball's position, similar to how a displacement sensor tracks an object's movement. A referee (strain sensor) monitors the players' stress during a game, while the scoreboard (temperature sensor) keeps track of how much time remains and the score, akin to how temperature sensors monitor conditions in a setting.

Classification by Working Principle

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Mechanical Sensors

- Electrical Sensors

- Optical Sensors

- Electromagnetic Sensors

- Ultrasonic Sensors

Detailed Explanation

Sensors are also classified based on how they operate. The main categories include:

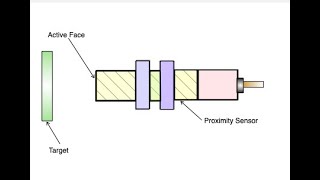

- Mechanical Sensors: Work by the physical movement or deformation of components due to the measured variable.

- Electrical Sensors: Utilize electrical phenomena, such as changes in resistance or capacitance, to measure specific quantities.

- Optical Sensors: Rely on light properties (such as intensity or wavelength changes) to gather data.

- Electromagnetic Sensors: Detect variations in electromagnetic fields, which can be applied in various measurement scenarios.

- Ultrasonic Sensors: Use sound waves beyond human hearing to measure distances or detect objects, often employed in construction surveys and inspections.

Examples & Analogies

Consider a camera (optical sensor), which captures light to create images, similar to how optical sensors work by detecting light variations. If we think about how a tuning fork (mechanical sensor) produces sound based on physical vibrations, it mirrors how mechanical sensors function by detecting movement or pressure changes in materials.

Classification by Mode of Operation

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Active Sensors (Require external power, e.g., strain gauges)

- Passive Sensors (Generate their own signal, e.g., thermocouples)

Detailed Explanation

Another way to categorize sensors is based on how they operate:

- Active Sensors: These require a source of external power to function. An example is a strain gauge, which needs electricity to operate.

- Passive Sensors: These generate a signal in response to the physical phenomenon they measure, meaning they do not require external power. A common example is a thermocouple, which produces a small voltage correlated to temperature without needing a power source.

Examples & Analogies

Imagine a battery-operated flashlight (active sensor) that needs batteries to function, just like active sensors need power to operate. On the other hand, think of a solar-powered garden light (passive sensor) that turns on at night and uses sunlight to operate, similar to how passive sensors generate their own signals based on the phenomena they sense.

Key Concepts

-

Displacement Sensors: Measure changes in position or movement.

-

Strain Sensors: Detect deformation in materials.

-

Load Sensors: Quantify forces acting on structures.

-

Temperature Sensors: Monitor environmental or structural temperatures.

-

Active Sensors: Require external power to function.

-

Passive Sensors: Generate their own signals without external power.

Examples & Applications

A laser distance meter is a displacement sensor used for monitoring structural deformations in bridges.

A strain gauge is an electrical sensor used to monitor the stress in concrete and steel structures.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To find our sensors, here's a handy cue; Displacement, strain, and load follow through.

Stories

Imagine a bridge standing tall, equipped with sensors monitoring all. A strain gauge whispers tales of tension, while a temperature sensor senses the thermal dimension.

Memory Tools

D-S-L-T-V-H-P-I-P (Displacement, Strain, Load, Temperature, Vibration, Humidity, Pressure, Inclination, Pore pressure uses D-S-L-T-V-H-P-I-P).

Acronyms

SWEEP for the working principles

Sensors Work by Electromagnetism

Electrical

and Piezoelectric principles.

Flash Cards

Glossary

- Displacement Sensors

Devices that measure the movement or position of structures.

- Strain Sensors

Sensors that detect deformation in materials due to stress.

- Load Sensors

Sensors used to measure the amount of force applied to an object.

- Temperature Sensors

Devices that measure ambient or structural temperature changes.

- Vibration Sensors

Sensors that capture vibrations to analyze structural integrity.

- Active Sensors

Sensors that require an external power source to operate.

- Passive Sensors

Sensors that generate their own signals without external energy.

Reference links

Supplementary resources to enhance your learning experience.