Electrical Resistance Strain Gauges

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Electrical Resistance Strain Gauges

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll learn about electrical resistance strain gauges. Who can tell me what happens to the electrical resistance of a conductor when it experiences strain?

Does it change?

Exactly! The resistance changes due to deformation. This property allows us to measure strain effectively. The more strain a material experiences, the more significant the resistance change.

So, it's all about measuring that change?

Correct! We use this principle to monitor various materials in civil engineering. Remember the acronym SENSORS—Strain, Electrical, Needs, Signal, Output, Real-time, Safety. It will help you remember their essential roles.

Installation of Strain Gauges

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss how strain gauges are installed. Why do you think proper installation is critical?

If they're not installed right, the data could be inaccurate?

Precisely! Strain gauges must be bonded securely to the surface of the material. This ensures accurate readings of the stress experienced by the structure. What materials can these gauges be used on?

Concrete and steel, right?

Absolutely! They’re versatile and can monitor a variety of materials. Remember: Proper Adhesion, Surface Cleanliness, and Alignment (P.A.S.C.A.), the key factors for ensuring effective installation.

Applications of Electrical Resistance Strain Gauges

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s explore the various applications of strain gauges. Can anyone give me an example of where strain gauges might be used?

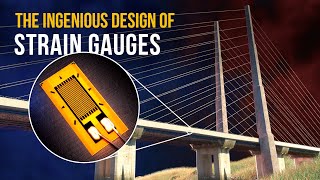

Maybe in bridges to monitor stress?

Yes, excellent example! They’re extensively used in bridges, beams, and other load-bearing structures to monitor stress conditions and prevent failure. How does this contribute to safety?

It helps identify weak points before they cause problems!

Exactly! Remember, Application Efficiency Enhances Safety (A.E.E.S.) is how we can think about the role of strain gauges - vital in maintaining structural integrity.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section provides an overview of electrical resistance strain gauges, detailing their operational principle based on strain-induced resistance changes, installation methods, and practical applications in monitoring stress conditions in various construction materials.

Detailed

Electrical Resistance Strain Gauges

Electrical resistance strain gauges are crucial components for measuring strain in materials such as concrete, steel, or composites. These devices operate on the principle that the resistance of a conductor changes when it is stretched or compressed. Strain gauges are typically bonded to the surface of structural members, enabling accurate assessments of stress under various load conditions. Proper use of strain gauges allows for enhanced safety and longer lifespan of structures by facilitating real-time data collection for structural health monitoring.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Principle of Operation

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

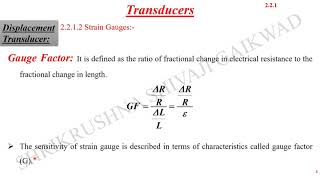

• Principle: Change in electrical resistance with strain

Detailed Explanation

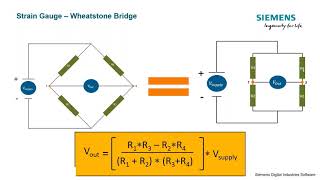

Electrical resistance strain gauges work on the principle that the resistance of a conductor changes when it is stretched or compressed. When the gauge is subjected to strain, its length changes, which leads to a change in its electrical resistance. This change can be measured and quantified, allowing engineers to determine the amount of strain on a structural member.

Examples & Analogies

Imagine pulling on a rubber band. As you stretch it, it gets longer and thinner, causing its resistance to change. This is similar to how strain gauges operate; they 'feel' the strain just like our hands feel the tension in the rubber band.

Installation Process

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Installation: Bonded on the surface of structural members

Detailed Explanation

To correctly measure strain, electrical resistance strain gauges must be installed properly. They are typically bonded directly to the surface of the structural member being studied. This ensures a tight connection that allows the strain experienced by the structure to be accurately transferred to the gauge. The surface must be prepared correctly to ensure that the adhesive used for bonding creates a strong attachment that can withstand environmental conditions.

Examples & Analogies

Think of gluing a piece of paper onto a wall — if the wall is dirty or moist, the paper won't stick well. Similarly, if the surface of the structure isn't properly cleaned and smoothed, the strain gauge may not bond well and could give inaccurate readings.

Applications of Strain Gauges

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Application: Monitoring stress in concrete, steel, or composite materials

Detailed Explanation

The primary use of electrical resistance strain gauges is to monitor stress and strain in various materials, such as concrete, steel, and composites. This is crucial in civil engineering for assessing the integrity of structures like bridges, buildings, and tunnels. By installing these gauges in strategic locations, engineers can obtain valuable data about how a structure is performing under loads and other environmental factors.

Examples & Analogies

Consider a large bridge that's regularly subjected to heavy traffic and environmental stress. Engineers install strain gauges to monitor its performance over time, much like a doctor regularly checks a patient’s vital signs to assess health. This way, they can detect issues early and maintain the bridge’s safety.

Key Concepts

-

Electrical Resistance: The property of a material that opposes electric current, which changes when the material is strained.

-

Strain Measurement: The process of quantifying deformation through the change in resistance indicative of applied stress.

-

Installation Importance: Proper bonding and installation of strain gauges are crucial for accurately capturing strain data.

Examples & Applications

Using strain gauges to monitor the structural health of bridges by detecting stress changes.

Implementing strain gauges on beams during construction to evaluate load conditions and prevent failure.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Strain and gain, resistance will wane, install it right, for data that's bright.

Stories

Once there was a bridge named Old Steel which was starting to crack. Engineers installed strain gauges on it, and through careful observation, they caught the issues in time, saved the bridge, and learned the importance of proper installations.

Memory Tools

BOND: Bond, Observe, Note, Data - key steps for effective strain gauge installation.

Acronyms

GAGES

Gauge

Apply

Gain

Ensure

Secure - steps for using strain gauges effectively.

Flash Cards

Glossary

- Electrical Resistance Strain Gauges

Devices that measure the amount of strain in a material by detecting changes in electrical resistance.

- Strain

Deformation per unit length that occurs in a material in response to applied stress.

- Bonding

The process of securely attaching a strain gauge to a surface to ensure accurate readings.

Reference links

Supplementary resources to enhance your learning experience.