Load Cells

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Load Cells

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to dive into load cells, a critical component in monitoring structural integrity. Can anyone tell me what a load cell does?

Is it something that measures weight or force?

Exactly! Load cells convert mechanical forces into electrical signals. Let’s remember that using the acronym 'FORCE'—F for Force, O for Output, R for Resistance change, C for Conversion, and E for Electrical signal.

How do they actually work?

Good question! Load cells typically use strain gauges, which react to deformation when a load is applied. This change is measured and converted into an electrical signal. Remember—deformation results in resistance change!

What types of load cells are there?

Great follow-up! We have three main types: hydraulic, pneumatic, and strain gauge types. Each serves different purposes based on the requirements of the applications.

Types of Load Cells

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's explore the types of load cells in detail. Who can tell me about hydraulic load cells?

They use hydraulic fluid to measure weight, right?

Correct! They measure the pressure of a hydraulic fluid to determine the load applied. Each type has unique strengths. For example, pneumatic load cells use air to measure force. Why might we choose one over the other?

Maybe based on the sensitivity needed or the type of materials involved?

Absolutely! Strain gauge load cells are more commonly used due to their versatility and precision. Remember: hydraulic systems can measure larger loads and pneumatic systems are great for lighter applications!

Applications of Load Cells

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss applications. Load cells are vital in ensuring safety in structures. Can anyone name a place we might use them?

In foundations or bridges?

Exactly! We often use them to monitor forces in foundations, beams, and columns. Remember, monitoring is key for predictive maintenance. Why is this important?

To prevent structural failures?

Correct! By monitoring these forces, we can identify potential issues early. It supports overall structural health monitoring!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Load cells utilize strain gauges to convert mechanical force into an electrical signal, allowing for precise measurements of loads in various civil engineering applications, including foundations and structural monitoring. Their key types include hydraulic, pneumatic, and strain gauge configurations, each suited for different applications.

Detailed

Load Cells

Load cells are critical components in the field of civil engineering, acting as sensors that convert force into an electrical signal through the use of strain gauges. They play a vital role in monitoring forces exerted on structural elements like foundations, beams, and columns. There are three main types of load cells: hydraulic, pneumatic, and strain gauge types, each with distinct operational principles and applications.

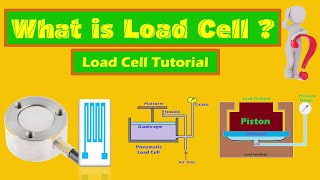

- Principle: Load cells operate on the principle of converting mechanical force into an electrical signal. As force is applied to the load cell, it deforms slightly, causing a change in electrical resistance, which is then translated into a measurable output.

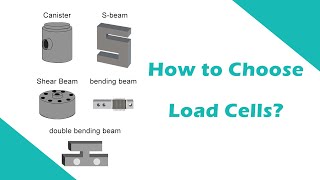

- Types of Load Cells:

- Hydraulic Load Cells: These utilize hydraulic fluid to measure force. The pressure of the fluid changes with the applied load, and this change is monitored using gauges.

- Pneumatic Load Cells: Similar to hydraulic, but using air pressure instead. They are often used where high sensitivity is needed in lighter applications.

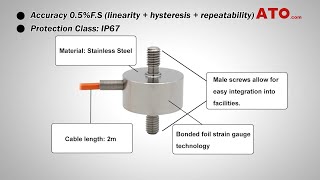

- Strain Gauge Load Cells: These are the most common type, using strain gauges bonded to a flexible element to detect deformation and convert it to an electrical signal.

- Applications: Load cells are extensively used for monitoring loads in foundations, beams, and columns, ensuring structural safety and integrity in various civil engineering projects. They provide crucial data that helps in predictive maintenance and overall structural health monitoring.

Understanding load cells is essential for civil engineers who need to maintain the safety and performance of infrastructure.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Principle of Load Cells

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Principle: Conversion of force into an electrical signal via strain gauges

Detailed Explanation

Load cells operate based on the principle of converting a physical force into an electrical signal. When a force is applied to the load cell, strain gauges attached to the load cell experience deformation. This deformation causes a change in the electrical resistance of the strain gauges, which is then converted into an electrical signal that corresponds to the amount of force applied.

Examples & Analogies

Imagine a simple bathroom scale. When you step on it, the weight you exert presses down on a load cell inside. Just like the load cell translates the weight into a number on the display, load cells in engineering structures measure the weight of buildings or bridges to ensure they can support the load.

Types of Load Cells

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Types: Hydraulic, pneumatic, and strain gauge type

Detailed Explanation

There are three main types of load cells: hydraulic, pneumatic, and strain gauge load cells. Hydraulic load cells use fluid pressure to measure weight, while pneumatic load cells use air pressure. Strain gauge load cells are the most common and work based on the electrical resistance changes in strain gauges when subjected to force. Each type has specific advantages and applications depending on precision requirements.

Examples & Analogies

Think of an elevator system in a building. The hydraulic load cells act like a pump that moves fluid to lift the elevator. Pneumatic cells could be used in factories to measure the pressure needed to lift heavy machinery, while strain gauge load cells are often found in precision instruments like scales or balances used in laboratories.

Applications of Load Cells

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Application: Monitoring forces in foundations, beams, and columns

Detailed Explanation

Load cells are crucial in civil engineering for monitoring the forces that structures like foundations, beams, and columns experience. By accurately measuring these forces, engineers can assess the structural integrity and safety of a building or bridge. Load cells provide real-time data that help in making informed decisions regarding maintenance and inspections.

Examples & Analogies

Consider the example of a bridge. Load cells are installed to monitor how much weight the bridge supports during rush hour or when heavy trucks pass. Just like a classroom teacher keeps an eye on students to ensure no one is straining under pressure, load cells help ensure that the bridge can handle the demands placed on it without failure.

Key Concepts

-

Force Conversion: Load cells transform mechanical force into an electrical signal.

-

Types of Load Cells: Includes hydraulic, pneumatic, and strain gauge load cells.

-

Application in Civil Engineering: Vital for monitoring forces in structural components.

Examples & Applications

A hydraulic load cell used to weigh large construction equipment during transport.

Strain gauge load cells installed in the foundations of a building to monitor load distribution.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Load cells measure force with style, to keep structures safe and worthwhile.

Stories

Imagine a bridge held by cables; every summer, it gets weighed by magic cells that whisper if it’s okay!

Memory Tools

Use 'LOAD' to remember: L for Load, O for Output, A for Accuracy, D for Deformation.

Acronyms

HPS

Hydraulic

Pneumatic

Strain- for all types of load cells.

Flash Cards

Glossary

- Load Cell

A sensor that converts mechanical force into an electrical signal.

- Strain Gauge

A device that measures deformation of an object.

- Hydraulic Load Cell

A type of load cell that measures force based on fluid pressure.

- Pneumatic Load Cell

A load cell that uses air pressure to measure force.

Reference links

Supplementary resources to enhance your learning experience.