Conclusion

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Fault Models

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will talk about the crucial role of fault models. Can anyone tell me why understanding fault models is important in electronic systems?

I think they help identify what can go wrong in a circuit?

Absolutely! Fault models simulate potential defects that can occur, which is essential for designing effective tests. It's like preparing for a pop quiz by understanding what types of questions might be asked.

Are there different types of faults we need to know about?

Good question! We have stuck-at faults, bridging faults, delay faults, and more. Think of it as different ways a car could fail, and understanding these helps us fix problems reliably.

How do we know if our tests can catch these faults?

That's where fault coverage comes into play! It measures how many faults a test suite can detect. A higher percentage means our testing is more effective!

So, more comprehensive tests lead to better system reliability?

Exactly! Always remember, the more we know about potential faults, the better we can test and ensure quality.

Testing Methodologies Overview

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss testing methodologies. Who can name some methodologies we might use in electronic testing?

I think functional testing is one?

Correct! Functional testing checks if the system performs as intended. However, it has its limitations because it doesn’t delve into the circuit’s internal workings.

What about structural testing? How does that work?

Great question! Structural testing, or white-box testing, examines the internal logic of the system. Think of it as checking the internal components of a clock to ensure each gear is working properly.

What’s BIST and how is it different?

BIST stands for Built-In Self-Test. It embodies self-testing capabilities within the design, like a car that can check its oil and tires without needing help. This is very useful for embedded systems.

I remember about boundary scan testing. What does JTAG stand for?

Exactly, JTAG is an interface that allows testing without accessing internal signals directly. It’s like using a remote control to access all features of your TV without opening it up.

So many testing methods, how do we choose?

It depends on the system’s requirements. Each testing method has its strengths, and sometimes we need to combine them for comprehensive coverage.

Got it, so choosing the right method helps ensure quality.

Exactly! We must match our methodologies to our systems.

Role of Industry Standards

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To finalize our discussion, let’s talk about the role of industry standards in testing.

What are some examples of these standards?

Some significant ones include IEEE 1149.1, which focuses on boundary scan testing, and ISO 26262, which is vital for safety in the automotive sector.

How do these standards affect testing procedures?

They provide guidelines to ensure consistency and quality across industries. Following the standards ensures everyone adheres to the same testing level, making it easier to ensure reliability.

So, they help us trust the quality of products?

Precisely! As products grow more complex, adhering to such standards helps maintain safety and performance. It’s like a referee ensuring everyone plays according to the rules.

Do companies choose which standards to follow?

Yes, but they often follow well-known standards that are industry-recognized to avoid issues with compatibility and safety.

I see how they play a critical role in the whole testing process.

Very true! Standards shape our approach and ensure that all stakeholders can trust the testing outcomes.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section highlights the integral role of fault models in simulating defects, testing methodologies in fault detection, and industry standards in providing consistency and reliability in testing procedures, emphasizing their growing significance in the ever-complex landscape of electronic systems.

Detailed

Conclusion

Understanding fault models, testing methodologies, and industry standards is crucial for ensuring the reliability and functionality of electronic systems. Fault models help simulate potential defects in a system, while testing methodologies provide the strategies to detect those faults efficiently. Industry standards ensure that testing procedures are consistent, reliable, and effective across different industries and applications. As electronic systems continue to grow in complexity, the importance of robust and comprehensive testing strategies will only increase, ensuring that modern systems meet the performance, safety, and quality expectations of consumers and industries alike.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Understanding Fault Models

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Understanding fault models, testing methodologies, and industry standards is crucial for ensuring the reliability and functionality of electronic systems.

Detailed Explanation

This chunk emphasizes the significance of familiarizing oneself with fault models, testing methodologies, and industry standards. These elements work together to ensure that electronic systems operate reliably and effectively. Understanding fault models allows engineers to predict where defects might occur, while methodologies serve as practical approaches to identifying and correcting those defects. This knowledge is fundamental for anyone involved in electronic system design and testing.

Examples & Analogies

Think of an engineer as a doctor. Just as doctors need to understand different illnesses (fault models) to diagnose patients accurately, engineers must recognize the potential failures in circuits to prevent malfunctions in electronic devices.

Role of Testing Methodologies

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fault models help simulate potential defects in a system, while testing methodologies provide the strategies to detect those faults efficiently.

Detailed Explanation

This chunk highlights how fault models and testing methodologies complement each other. Fault models act like a map, showing where potential issues may exist within a circuit. Testing methodologies then serve as the tools or strategies used to navigate this map effectively—allowing engineers to locate and fix defects before the electronic systems are deployed.

Examples & Analogies

Imagine you're trying to find lost treasure (the faults in a circuit). The fault models represent clues that guide you to potential locations, while testing methodologies are like the treasure maps that lead you straight to the treasure, ensuring you find it efficiently.

Significance of Industry Standards

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Industry standards ensure that testing procedures are consistent, reliable, and effective across different industries and applications.

Detailed Explanation

The chunk explains the importance of adhering to industry standards in the testing process of electronic systems. These standards provide a set of established guidelines that ensure testing methods are not only reliable but also consistent across various applications. This consistency is vital for both manufacturers and consumers, as it builds trust and ensures that electronic devices meet quality expectations.

Examples & Analogies

Consider industry standards as the rules of a board game. Just as players need consistent rules to ensure a fair and enjoyable game, electronics manufacturers must follow established standards to ensure their products are safe, reliable, and effective.

Growing Complexity of Electronic Systems

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

As electronic systems continue to grow in complexity, the importance of robust and comprehensive testing strategies will only increase, ensuring that modern systems meet the performance, safety, and quality expectations of consumers and industries alike.

Detailed Explanation

This chunk addresses a crucial trend in the electronic industry: growing complexity in systems. As these systems become more intricate, the methods for testing them must also evolve. Comprehensive testing strategies become essential to manage and validate the increased number of components and potential interactions between them. This ongoing evolution helps ensure that electronic devices perform safely and effectively, meeting the demands of users and industries.

Examples & Analogies

Think of technological advancements like a high-tech car with many features (navigation, automated driving, security systems). With every new feature, the testing process must become more thorough to ensure that everything works together smoothly, just like a conductor managing a complex orchestra where every instrument must be in harmony for a beautiful performance.

Key Concepts

-

Fault Models: Represent types of defects in circuits to guide testing strategies.

-

Testing Methodologies: Strategies employed to verify that systems are free from defects.

-

Industry Standards: Established norms that ensure reliability and consistency in testing procedures.

-

Fault Coverage: The effectiveness of a test suite in identifying faults within a system.

Examples & Applications

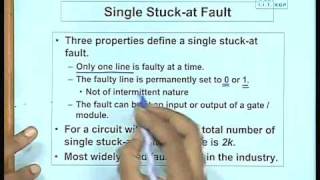

A stuck-at fault occurs when a signal in a digital circuit is fixed at a logic high (1) or low (0), affecting the functionality of the circuit.

Boundary scan testing allows access to integrated circuits' pins for testing without needing physical access to the internal signals.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Fault models help define, the issues that align, with testing that’s divine!

Stories

Imagine a ship sailing through stormy waters. Fault models are like the crew with maps and tools, preparing for every storm (defect) that could arise during the journey of electronic design.

Memory Tools

For testing methods, remember 'FBSJB' - Functional, Boundary Scan, Structural, JTAG, Built-In Self-Test.

Acronyms

R.E.A.L. - Reliability (what we aim for), Effectiveness (of tests), Accuracy (in faults detection), Legitimacy (from standards).

Flash Cards

Glossary

- Fault Model

A representation of possible defects in a system that helps in creating test strategies.

- Fault Coverage

The percentage of faults that can be detected by a given test suite.

- Functional Testing

A testing methodology to verify that the system performs its intended function.

- Structural Testing

Testing that involves checking the internal structure of a system.

- BuiltIn SelfTest (BIST)

A methodology that allows a system to test itself without external equipment.

- Boundary Scan Testing

Testing using a standardized interface to check integrated circuits' boundary pins.

- Industry Standards

Established regulations that guide the testing and verification processes for electronic systems.

Reference links

Supplementary resources to enhance your learning experience.