Introduction to Fault Models, Testing Methodologies, and Industry Standards

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Overview of Fault Models

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, let's talk about fault models. A fault model is essentially a blueprint of potential failures within a circuit. Can anyone describe what you think a fault model might represent?

I think it’s about the different ways a circuit can fail?

Exactly! Fault models cover various types of defects, like stuck-at and bridging faults. Remember, a stuck-at fault happens when a signal stays fixed at a certain value despite the inputs. Can anyone give me an example of a scenario where this might occur?

Maybe if there was a manufacturing defect that was not caught?

Yes! Manufacturing defects are common causes. Let’s summarize: Fault models help us predict and strategize around failures. They guide us in efficient testing designs.

Importance of Testing Methodologies

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss testing methodologies. Why do you think we need different methodologies for testing electronic systems?

Because systems have different needs based on their function!

Exactly! For instance, functional testing checks whether the system performs as expected. However, it doesn’t give us insight into the internal workings of the circuit. Which methodology could fill that gap?

Structural testing because it looks at the internal structure?

You got it! Structural testing, or white-box testing, does evaluate the internal structure. It’s essential for identifying faults deep within the circuit. At the end of the day, each methodology targets specific issues.

Understanding Industry Standards

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s cover industry standards. Why do you think standards like IEEE 1149.1 are critical for testing?

They probably make sure everyone tests the same way, right?

Correct, Student_1! Standards ensure uniformity and quality across different systems, enhancing reliability. For example, the IEEE 1149.1 standard, also known as JTAG, allows for accessing device states without invasive testing. What is the significance of having such a standard?

It must help with compatibility and make it easier to test new technologies!

Very true! The importance of standards cannot be undervalued as they lay the groundwork for testing strategies.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we examine the essential concepts of fault models, which describe the types of defects in circuits, along with testing methodologies that facilitate fault detection and the industry standards that provide guidelines for effective testing strategies. Understanding these aspects is vital for ensuring the reliability and quality of electronic systems.

Detailed

In the realm of electronic systems, assuring reliability, performance, and safety is crucial. This section presents an overview of fault models, testing methodologies, and industry standards that are fundamental to verifying and validating electronic systems. Fault models categorize potential defects—such as stuck-at, bridging, and delay faults—while testing methodologies, including functional testing and built-in self-test, outline strategic approaches to detect these faults. Additionally, industry standards, such as IEEE 1149.1, ensure consistency across various systems and help implement effective testing strategies. A thorough understanding of these concepts is essential for developing robust testing procedures that maximize fault detection, thereby enhancing product quality.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Verification and Validation

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The process of verifying and validating electronic systems is essential to ensuring their reliability, performance, and safety.

Detailed Explanation

Verification and validation are critical steps in the development of electronic systems. Verification checks if the system meets specific requirements, while validation ensures that it fulfills its intended purpose. These processes help identify defects before the product is released, thereby ensuring high reliability, effective performance, and safety for users.

Examples & Analogies

Imagine you are baking a cake. Verification is like checking the recipe to ensure you have all the right ingredients, while validation is tasting the cake to confirm it's delicious and meets your expectations before serving it to guests.

Role of Fault Models

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A key component of this process is understanding the fault models, testing methodologies, and industry standards that guide how systems are tested and evaluated.

Detailed Explanation

Fault models help identify possible defects that can occur in electronic systems. They serve as frameworks or blueprints for developing various testing scenarios to expose potential issues. This understanding is critical to creating effective tests that can reveal flaws before products are deployed.

Examples & Analogies

Consider fault models as a map you use when exploring a new city. Just like a map highlights potential trouble spots or areas worth checking out, fault models outline where defects might appear in a circuit, guiding you to where you should focus your testing efforts.

Relationship Between Testing Methodologies and Fault Models

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fault models represent the types of defects that might occur in a circuit, while testing methodologies outline how to detect those faults effectively.

Detailed Explanation

Testing methodologies are the strategies and techniques applied to identify faults in circuits as identified by fault models. The relationship is sequential: fault models inform testing methodologies about what needs to be tested and how, thus ensuring that the testing is thorough and relevant.

Examples & Analogies

Think of this process like preparing for an exam. You have a study guide (fault model) that lists all the possible topics that could be on the test. You then choose the study techniques (testing methodologies) best suited to master those topics, ensuring you’re well-prepared.

Importance of Industry Standards

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Industry standards provide the framework and guidelines for implementing testing strategies and ensuring consistency across different systems and industries.

Detailed Explanation

Industry standards are established guidelines that help unify testing practices across the electronic industry. They ensure that the tests are not only comprehensive but also reliable and consistent, which allows products to be assessed uniformly regardless of where they are produced or tested. This consistency is vital for trust and reliability in the technology we use.

Examples & Analogies

Consider industry standards as traffic rules. Just as traffic rules provide a consistent framework for drivers to follow, ensuring safety and order on the roads, industry standards do the same for electronic systems, promoting consistent quality and reliability across different products.

Essential Concepts Summarized

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Understanding these concepts is crucial for designing testable circuits and developing robust testing procedures that maximize fault detection and minimize errors in production.

Detailed Explanation

To effectively design electronic circuits, engineers must grasp fault models and testing methodologies. This knowledge allows for the creation of systems that can effectively detect faults during testing, minimizing the risk of errors during production and subsequent consumer use. This proactive approach to testing is essential for ensuring high-quality electronic products.

Examples & Analogies

Think of designing electronic circuits like building a bridge. Knowledge of potential structural weaknesses (fault models) and rigorous testing methods ensures the bridge can withstand loads (testing methodologies), leading to a safe and successful design. Ignoring these aspects could lead to failure or disregard of safety standards, just like a poorly designed bridge could collapse.

Key Concepts

-

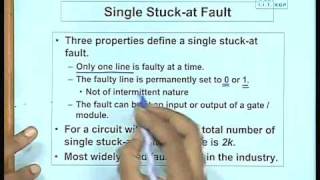

Fault Models: Represent potential defects within electronic circuits, guiding testing strategies.

-

Testing Methodologies: Strategies for ensuring the proper functionality and performance of electronic systems.

-

Industry Standards: Guidelines that promote consistency and quality in electronic design and testing.

Examples & Applications

Stuck-at faults can occur in digital circuits where a line remains high or low due to a defect, causing incorrect operations.

JTAG is a widely used industry standard that allows for easier testing and verification of complex integrated circuits.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If a signal won't change, it’s stuck like a chain, that’s a stuck-at fault in the electronic plane.

Stories

Imagine a busy highway where cars are expected to flow smoothly. A stuck-at fault is like a car that stops and blocks the road, disrupting all traffic behind it.

Memory Tools

BASIC: BIST, At-speed testing, Structural testing, Industry Standards, and Coverage – remember the types of testing!

Acronyms

FET

Fault Models

Evaluation Methodologies

Testing Standards – key areas of focus in system testing.

Flash Cards

Glossary

- Fault Model

A representation of potential faults in electronic circuits, helping to predict and detect defects.

- StuckAt Fault

A defect where a signal line in a circuit remains fixed at a specific logic value regardless of inputs.

- Bridging Fault

An unintended connection between signal lines caused by manufacturing defects, leading to incorrect circuit behavior.

- Testing Methodology

Strategies and techniques used to verify the functionality of electronic systems and detect faults.

- Industry Standards

Established guidelines that ensure consistency and reliability in the design and testing of electronic systems.

Reference links

Supplementary resources to enhance your learning experience.