Structural Testing

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Structural Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome everyone! Today, we will explore structural testing. Can anyone tell me what you think structural testing involves?

I guess it tests the structure of the circuit, right?

Exactly! Structural testing, also known as white-box testing, focuses on the internal components and connections of the circuit. It's essential to ensure all parts work as intended. Why do you think this is important?

We need to catch any problems that might not show up just by checking inputs and outputs!

That's right! Identifying issues early can save time and cost in production.

Scan-Based Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about scan-based testing. Can anyone describe how scan-based testing works?

Doesn’t it create chains to control and monitor internal states?

Exactly, great point! Scan chains allow us to easily access different internal components during testing. This method enhances fault detection significantly because it lets us isolate and test individual logic elements. Can anyone think of an advantage of this method?

It probably makes debugging a lot easier since we can pinpoint the exact area that’s failing!

Absolutely! Debugging becomes much more manageable.

Benefits of Structural Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss the benefits of structural testing. Why do you think structural testing is crucial in modern electronics?

It helps ensure that everything is functioning correctly inside the circuit!

Correct! It ensures all internal components work as expected, which is especially necessary for complex designs. Another important aspect is enhancing fault coverage. Can anyone explain what fault coverage means?

It must be the percentage of faults that can be detected by the testing process!

Exactly! Higher fault coverage means our test patterns can detect more potential issues, leading to higher quality in production.

Comparison with Functional Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s compare structural testing with functional testing. What do you think is the main difference?

Functional testing looks at input and output while structural testing inspects the inside!

Spot on! Functional only verifies the output correctness based on the inputs, but structural testing digs deeper, ensuring structural integrity. Which do you think might miss certain defects?

Functional testing might miss internal flaws.

Correct! Structural testing is critical for comprehensive evaluation.

Conclusion of Structural Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

As we wrap up, can anyone summarize what we learned today about structural testing?

It tests the internal structure of circuits and uses scan chains to enhance observation!

Great summary! Remember, structural testing is vital for identifying faults not visible in functional testing. Why is this important for product reliability?

It keeps consumers safe and ensures products perform as they should!

Excellent! Always keep in mind the importance of robust testing methodologies in developing quality electronic systems.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Structural testing, also known as white-box testing, evaluates the internal architecture of a system to ensure all components operate correctly under different conditions. This method often employs scan-based testing techniques to access and control internal states, enhancing fault detection capabilities.

Detailed

Structural Testing

Structural testing, referred to as white-box testing, is a critical methodology in the verification and validation of electronic systems. Unlike functional testing, which examines the overall behavior of a system based on input-output responses, structural testing delves into the internal workings of a circuit. It ensures that all nodes and components of the circuit are thoroughly tested, validating that the overall structure meets design specifications.

A common technique used in structural testing is scan-based testing, which employs scan chains to expose the internal states of the circuit for easier observation and control. This technique allows testers to check individual logic elements, thus enhancing the fault detection process.

The importance of structural testing lies in its ability to identify issues that functional testing may miss, particularly in complex circuits, making it an essential component in creating reliable, high-quality electronic systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Structural Testing

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Structural testing, also known as white-box testing, involves testing the internal structure of a system. This type of testing focuses on ensuring that all parts of the circuit are tested and that the system operates as expected across all internal nodes and components.

Detailed Explanation

Structural testing, often referred to as white-box testing, differs from other testing methods because it examines the internal workings of the system rather than just its outputs. This means that testers have access to the system's internal logic and structure, which allows them to verify that every part functions correctly. The primary focus is on ensuring that the system behaves as expected at all levels, from individual components to the entire architecture.

Examples & Analogies

Think of structural testing like a mechanic inspecting a car's engine rather than just ensuring it runs well during a test drive. By looking inside the engine, the mechanic can identify specific issues, ensuring that every part works together harmoniously.

Scan-Based Testing

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Scan-Based Testing: Scan-based testing uses scan chains to expose internal states of the circuit for easy observation and control during testing. This method allows testing of individual logic elements, such as flip-flops, and is commonly used in modern digital ICs.

Detailed Explanation

Scan-based testing is a technique that utilizes 'scan chains' to manage how internal data is accessed and tested. A scan chain is a series of flip-flops connected in a way that allows data to be shifted through them easily. By doing this, testers can observe the state of various parts of the circuit and manipulate them for testing purposes. This is particularly valuable in modern digital integrated circuits (ICs) where ensuring the reliability of individual components is critical. The ability to control internal states helps in efficiently identifying faults.

Examples & Analogies

Imagine a train with several carriages, where each carriage can be opened to inspect the cargo inside. Scan-based testing is like opening each carriage to check its contents, ensuring everything is in order. Inspecting each carriage ensures that the entire train operates smoothly, just like testing each part of a circuit ensures overall functionality.

Key Concepts

-

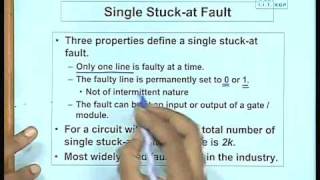

Structural Testing: A testing methodology focusing on internal components of electronic systems.

-

Scan-Based Testing: A method that helps in observing internal states through scan chains.

-

Fault Coverage: Indicates the effectiveness of the testing by measuring how many possible faults can be detected.

Examples & Applications

A scan-based test might check each flip-flop in a digital circuit to verify its state and operation.

When using structural testing on a microprocessor, testers can isolate and evaluate the performance of individual cores.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

How to make a circuit right, test the structure with all your might!

Stories

Imagine a detective investigating a complex case, looking closely at all clues. That’s like structural testing—dig deep to find every hidden fault!

Memory Tools

Remember the acronym 'SHAPE' for structural testing: S = Structure, H = Holistic approach, A = Analyze components, P = Performance verification, E = Error detection.

Acronyms

SCAN can help you remember Scan-Based Testing

= States

= Control

= Access

= Nodes.

Flash Cards

Glossary

- Structural Testing

Testing focused on evaluating the internal structure and components of a system to ensure proper operation.

- ScanBased Testing

A testing technique that employs scan chains to access and control internal states of a circuit.

- Fault Coverage

The percentage of faults that can be detected by a given set of test patterns.

Reference links

Supplementary resources to enhance your learning experience.