Fault Simulation and Fault Coverage

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Fault Simulation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss fault simulation. Can anyone tell me why simulating faults might be essential in testing electronic systems?

I think it's to see if tests can catch any problems that might happen during actual use.

That's correct! Fault simulation allows us to mimic real-world failures and check if our testing methods can find these issues before they affect performance. Could someone explain what we mean by 'fault coverage'?

Isn't it the percentage of faults that a test suite can identify?

Exactly! Higher fault coverage means our test patterns are more effective. We'll return to this as we continue our discussion.

Importance of a Comprehensive Test Suite

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

When we talk about a comprehensive test suite, why do you think high fault coverage is crucial?

It means fewer chances for defects to go unnoticed, right?

Yes! Lower defect rates improve overall reliability. If we have high fault coverage, we can trust that our system will perform reliably. Can anyone think of a situation where low fault coverage might lead to problems?

Maybe in critical systems like medical devices? A fault there could be really serious.

That's a great example! Systems like those require meticulous testing due to the potential consequences of failure.

Challenges in Achieving Higher Fault Coverage

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss some challenges in achieving high fault coverage. What do you think makes it difficult?

Maybe the complexity of electronic systems? More components could mean more potential faults.

Correct! As systems become more intricate, simulating every potential fault becomes more challenging. What could help us overcome these challenges?

We could use automated tools for simulation to speed up the process.

Absolutely, leveraging automation can significantly enhance our fault coverage assessments.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores fault simulation, a critical process to mimic real-world faults in electronic systems, and discusses fault coverage, which measures how effectively a generated test suite can detect these faults. Higher fault coverage signifies a more robust testing process.

Detailed

Fault Simulation and Fault Coverage

Fault simulation is a vital aspect of electronic system testing, allowing engineers to replicate faults that might occur in real-world scenarios. By simulating various fault types, the effectiveness of a test suite in detecting these faults can be assessed. The primary goal of fault simulation is to verify that the generated test patterns are capable of identifying as many faults as possible.

Key Components:

- Fault Simulation: It involves intentionally introducing faults within a circuit model to assess whether existing test patterns can detect them. This process helps designers understand potential weaknesses in testing methods.

- Fault Coverage: This refers to the percentage of detectable faults by a particular test suite. A higher fault coverage percentage implies that the test patterns are more comprehensive, indicating stronger test quality and reliability. As the complexity of electronic systems increases, ensuring high fault coverage becomes critical for maintaining product performance and safety.

In summary, fault simulation and coverage assessment are crucial for validating that electronic systems can perform reliably under various fault conditions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Fault Simulation

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fault simulation involves simulating the occurrence of faults in the system to verify whether the test suite can detect these faults.

Detailed Explanation

Fault simulation is a technique used to mimic potential faults that could occur in an electronic system. The primary goal is to test if the existing suite of tests can identify these faults. This process is crucial because it helps to uncover weaknesses in the testing approach and ensures that the tests are not blind to certain faults.

Examples & Analogies

Think of fault simulation like a fire drill. Just as a fire drill prepares everyone in a building for what to do in case of a real fire, fault simulation prepares your testing suite to handle genuine faults effectively. It ensures that when a fault occurs, the system's testing process has been practiced enough to respond correctly.

Understanding Fault Coverage

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The aim is to ensure that the generated test patterns can detect as many faults as possible. Fault coverage refers to the percentage of faults that can be detected by a given test suite.

Detailed Explanation

Fault coverage is a metric that indicates the effectiveness of a test suite. It is calculated as the percentage of detectable faults relative to the total number of faults that could potentially occur. A higher fault coverage percentage means that the tests are more comprehensive and effective in identifying faults, leading to an overall improvement in the quality of the system being tested.

Examples & Analogies

Imagine you’re a teacher assessing students' knowledge through a test. If the test covers all the topics you've taught, then it has high coverage. If it misses some chapters, then the coverage is low. Just like in testing electronic systems, you want to ensure that the test includes all areas to maximize the chances of spotting mistakes.

Importance of High Fault Coverage

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A higher fault coverage indicates that the test patterns are more comprehensive, resulting in higher test quality.

Detailed Explanation

Achieving high fault coverage is essential because it reduces the risk of undetected defects in a system. When fault coverage is high, it means that the majority of potential faults have been accounted for and can be tested against. This not only enhances the reliability of the system but also builds trust in the product's performance amongst users and stakeholders.

Examples & Analogies

Consider a road safety inspection for vehicles. If the inspection checks all crucial safety features—brakes, lights, tires, etc.—then you can be more confident that the vehicle is safe to drive. Similarly, high fault coverage in testing ensures that most potential points of failure in a system are addressed, which enhances its overall reliability.

Key Concepts

-

Fault Simulation: The process of mimicking faults in circuits to evaluate test suites.

-

Fault Coverage: The percentage of detectable faults signifying test effectiveness.

Examples & Applications

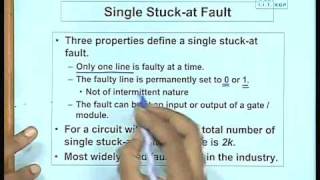

If a circuit experiences a stuck-at fault where a signal remains fixed, fault simulation tests if the associated test patterns can detect this.

In a high-speed circuit with potential delay faults, fault simulation assesses if the timing tests can identify these delays.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To catch all faults you must permit, simulation makes them real a bit.

Stories

Imagine a team building a spaceship. They simulate every possible failure - imagine if a rocket has a stuck signal! They need to ensure the tests catch these failures before launch.

Memory Tools

F-S-F-C (Fault Simulation-Fault Coverage) - Fault Simulation checks for faults, Fault Coverage tells how many we catch.

Acronyms

FC - Fault Coverage means For Comprehensive testing, capture as many faults as you can!

Flash Cards

Glossary

- Fault Simulation

The process of mimicking faults in a system to evaluate the efficiency of a test suite in detecting these faults.

- Fault Coverage

The percentage of faults that can be detected by a given test suite, indicating its effectiveness in testing.

Reference links

Supplementary resources to enhance your learning experience.