Introduction to Key Concepts: Fault Models, Testing Methodologies, and Industry Standards

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Fault Models

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start with fault models. Can anyone explain what a fault model represents in electronic systems?

Is it about the different types of failures that can happen in a circuit?

Exactly, Student_1! Fault models outline potential defects, guiding how we develop test patterns to identify these issues. Can anyone name a type of fault model?

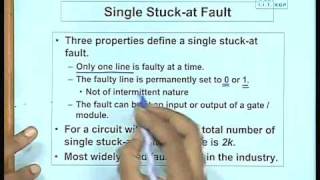

I think one is a stuck-at fault, where a signal is fixed at 0 or 1.

Right! Stuck-at faults are common in digital circuits. Remember, they can occur due to manufacturing defects or aging. Let's look at another type: bridging faults. What do you think happens there?

Is it when two lines unintentionally connect, causing incorrect signals?

Spot on! Great job, Student_3. Bridging faults can really impact circuit performance. Let's summarize: fault models help us simulate potential issues and decide on effective testing methods.

Testing Methodologies

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s move on to testing methodologies. Who can tell me about functional testing?

Functional testing checks if the system does what it's supposed to do, right?

That's correct, Student_4! It's crucial but can miss internal problems. What about structural testing? What does that involve?

It tests the internal structure of the circuit, ensuring everything works together?

Exactly! This method assures that the system operates as intended. Remember the term 'scan-based testing'? What do you think it implies?

Does it involve using scan chains to access internal states?

Yes! Scan-based testing makes it easier to check individual components. Now, let's summarize: functional testing focuses on outputs, while structural testing targets internal fidelity.

Understanding Industry Standards

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss industry standards. What is the purpose of standards like IEEE 1149.1?

They set guidelines for testing electronic systems, making sure they're consistent.

That's right! Standards ensure reliability and interoperability across systems. What about the significance of ISO 26262?

Is it related to safety testing in automotive applications?

Correct! It provides strict guidelines for automotive safety, especially for electronic systems. Let’s recap: industry standards promote quality and consistency in electronic testing.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Understanding fault models, testing methodologies, and industry standards is critical for ensuring the reliability, performance, and safety of electronic systems. The section discusses various types of faults, testing methods, and industry benchmarks that guide electronic system validation and design.

Detailed

Introduction to Key Concepts: Fault Models, Testing Methodologies, and Industry Standards

The verification and validation processes for electronic systems are essential for guaranteeing reliability and safety. Central to these processes are fault models that describe potential defects, testing methodologies that detail detection strategies, and industry standards that ensure consistency and quality in testing. This section emphasizes the significance of these concepts in modern electronic design, aiming to foster an understanding necessary for producing robust and testable circuits.

Fault Models in Electronic Systems

Fault models form the basis of test pattern development. They help simulate various failure mechanisms in circuits, such as stuck-at faults, bridging faults, delay faults, transition faults, open circuit faults, and inductive/capacitive faults. Each model represents different physical issues that may arise in electronic components. Fault simulation tests how well the developed test suite can identify these faults, with fault coverage reflecting the percentage of detectable faults by the tests utilized.

Testing Methodologies

This section outlines critical testing methodologies:

- Functional Testing numbers as fundamental checks of system behavior.

- Structural Testing enables exploration of internal components and designs.

- Built-In Self-Test (BIST) provides self-diagnostic capabilities integrated within the system.

- Boundary Scan Testing (JTAG) uses a standard interface to assess digital ICs without physical probes.

- Parametric Testing focuses on measuring electrical parameters to assess performance.

- At-Speed Testing confirms operational integrity under normal performance conditions.

Industry Standards for Testability

Emphasizing the establishment of quality assurance across electronic design, this section reviews several key standards: IEEE 1149.1 (JTAG), IEEE 1500 (Core Testability), ISO 26262 (Automotive Safety Testing), and MIL-STD-883 (Military Testing). These frameworks ensure compliance with industry requirements for testing and validating electronic systems, essential for safety and operational efficiency.

In conclusion, the intersection of fault models, testing methodologies, and industry standards becomes increasingly relevant as the complexity of electronic systems rises, calling for comprehensive testing strategies to meet consumer and industry expectations.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Verification and Validation in Electronic Systems

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The process of verifying and validating electronic systems is essential to ensuring their reliability, performance, and safety. A key component of this process is understanding the fault models, testing methodologies, and industry standards that guide how systems are tested and evaluated.

Detailed Explanation

Verification involves checking that a product meets the specifications before it is made, while validation ensures that the product fulfills its intended purpose and is safe and reliable for use. Understanding key concepts such as fault models, which represent potential defects in circuits, and testing methodologies, which are strategies for detecting these defects, is critical in this process. Industry standards help set a consistent framework for testing across various systems and industries.

Examples & Analogies

Imagine a car manufacturer wants to ensure that their vehicles are safe. They would first verify individual components, like brakes and lights, to ensure they meet design specifications. Then, they would validate that when these parts work together, the car operates safely on the road. Just like that, electronic systems undergo similar processes to ensure they perform reliably.

Fault Models Explained

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fault models represent the types of defects that might occur in a circuit, while testing methodologies outline how to detect those faults effectively.

Detailed Explanation

Fault models categorize possible failures in a system, such as a wire being stuck at a certain voltage instead of changing as expected. Testing methodologies then provide systematic approaches to identify these faults during testing. Essentially, fault models help engineers anticipate issues, while methodologies provide the toolset to uncover these defects.

Examples & Analogies

Think of a medical check-up where a doctor anticipates various health problems based on family history (fault models), and then conducts different tests (testing methodologies) to find out if those problems actually exist in the patient. This proactive approach helps prevent major health issues.

Role of Industry Standards

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Industry standards provide the framework and guidelines for implementing testing strategies and ensuring consistency across different systems and industries.

Detailed Explanation

Industry standards set benchmarks for quality and consistency, ensuring that testing methods and results are comparable across different manufacturers and systems. This helps maintain reliability and safety, enabling different companies to work together seamlessly, as they adhere to the same testing criteria.

Examples & Analogies

Consider building codes in construction. They ensure that buildings are safe and up to standard regardless of who builds them. Similarly, industry standards in electronics assure that products from different manufacturers can be integrated and relied upon effectively.

Crucial Aspects of Designing for Testability

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Understanding these concepts is crucial for designing testable circuits and developing robust testing procedures that maximize fault detection and minimize errors in production.

Detailed Explanation

Designing testable circuits means creating systems that are easy to check for faults. By understanding the fault models and methodologies, engineers can design circuits in a way that allows easier testing and troubleshooting. This proactive design leads to higher quality products with fewer errors during production.

Examples & Analogies

Think of building a puzzle with extra clues and open space for checking completed sections. This makes it easier to identify which pieces are missing or misplaced. Similarly, designing electronic circuits with testability in mind allows engineers to quickly pinpoint issues, leading to efficient troubleshooting.

Key Concepts

-

Fault Models: Represent potential defects in circuits and guide testing strategies.

-

Testing Methodologies: Include functional testing, structural testing, BIST, and JTAG.

-

Industry Standards: Provide guidelines for consistency and quality in testing and design.

Examples & Applications

A stuck-at fault can occur due to a manufacturing defect, causing a signal line to remain at a logic value.

In structural testing, a circuit’s internal nodes are tested to ensure each component functions properly.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Faults that stick can cause a glitch, they keep a signal from its switch.

Stories

Imagine a busy highway; each car represents a signal. A stuck car causes a jam, similar to a stuck-at fault freezing communication. When two cars collide, it's like a bridging fault disrupting flow.

Memory Tools

FIBBS (Functional, Internal, BIST, Boundary Scan, Safety) - remembering the key testing methodologies.

Acronyms

ASP (Automotive Safety Standards) for remembering ISO 26262 and its focus on safety in vehicles.

Flash Cards

Glossary

- Fault Model

A representation of potential defects or failures in a circuit, crucial for developing test patterns.

- StuckAt Fault

A fault where a signal remains at a fixed value, either high or low, regardless of input.

- Bridging Fault

A fault that occurs when two signal lines are unintentionally connected, disrupting normal operation.

- Functional Testing

A testing method that verifies whether a system performs its intended functions correctly.

- Structural Testing

Testing that examines the internal structure of a system to ensure its components work as intended.

- BuiltIn SelfTest (BIST)

A methodology that allows a system to perform self-tests without external equipment.

- Boundary Scan Testing (JTAG)

A testing method that uses a standardized interface to access the boundary pins of integrated circuits.

- ISO 26262

An automotive safety standard that provides guidelines for testing electronic systems in vehicles.

Reference links

Supplementary resources to enhance your learning experience.