Major Pipe Head Loss (Due to Friction)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Major Head Loss

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to dive into major head losses caused by friction in pipelines. Can anyone tell me how friction affects fluid flow?

I think it slows down the flow, right?

Exactly! Friction between the fluid and the pipe wall causes energy loss, which we quantify in terms of head loss using the Darcy-Weisbach equation. Let's remember it with the acronym *H-L-F*, for Head Loss due to Friction.

What factors influence this head loss?

Good question! Factors include the length and diameter of the pipe and the fluid's velocity. Now, let’s apply what we've learned to real-world examples to see how to calculate it using these factors.

Bernoulli’s Equation Application

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we'll apply Bernoulli's equation to find pressure differences in our system. Who can remind us what Bernoulli’s equation relates to in fluid dynamics?

It relates pressure, velocity, and height!

Great! Remember, we also consider major head losses while applying it. So, how would we modify Bernoulli's equation to include head loss?

We subtract the head loss from the total pressure!

Exactly! That’s a perfect summary. This adjustment allows us to find pressure at different points in the system accurately.

Calculating Discharge with Minor Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now we've covered major losses, let’s look at how this plays out when calculating discharge, specifically with both major and minor losses involved.

Are minor losses like those from bends or valves considered in these calculations?

Exactly! Even though we focused primarily on major losses, minor losses significantly impact flow, especially when accounting for how much water can be effectively discharged.

Can you give us an example?

Sure! If we know the total head loss is 30m, part of this would be due to friction (major losses), and any losses from elements like bends or valves would be minor losses. We incorporate both to solve for discharge effectively.

Example Problem Solving

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s solve an example problem together! If we have a pipe with a diameter of 0.7m and a total length of 6 km, what would be our first step?

We should calculate the friction factor first!

Exactly! Then, we can plug this into our Darcy-Weisbach equation to compute the head losses. Remember to keep track of units!

Why are units so important?

Units ensure accuracy in calculations, which is key in engineering applications. Let’s finish this example by calculating the discharge.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

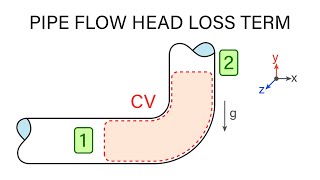

The section delves into the understanding of major head losses resulting from friction in pipes, detailing the methods to compute these losses using principles from fluid mechanics, particularly Bernoulli's equation, while also acknowledging minor losses which are generally excluded from the primary calculations.

Detailed

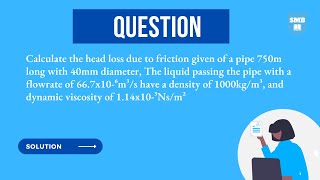

Major Pipe Head Loss (Due to Friction)

This section focuses on major head losses in fluid systems due to friction, essential for understanding the dynamics of fluid flow in pipelines. The primary formula used for calculation is based on the Darcy-Weisbach equation, which accounts for the friction between the fluid and the pipe wall. It is also important to understand minor losses such as those caused by bends, valves, and other fittings; although the section primarily concentrates on major losses, these factors can influence overall system efficiency.

Key Points:

- Major Loss Calculation: The major head loss is computed using empirical equations, specifically the Darcy-Weisbach equation.

- Minor Losses Consideration: Minor losses due to components such as bends and valves are acknowledged but not computed in detail here.

- Bernoulli’s Equation: The section emphasizes the use of the modified Bernoulli's equation to compute pressure throughout the system, allowing for the application of known values to determine the pressure at any point in the system.

- Practical Examples: The section includes examples that illustrate practical applications of these calculations in real-world scenarios, enhancing comprehension of theoretical concepts.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Head Loss due to Friction

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So that means I know the head losses that is what is computed here by substituting this value. There will be minor losses like bend losses, valve losses, the entry and exit losses all the components, this entry and exit loss we do not consider it here only the bend loss and valve loss we compute it which we have these values.

Detailed Explanation

In this chunk, we are introduced to the concept of head loss due to friction in pipes. Head loss refers to the reduction in the total mechanical energy of the fluid as it moves through a pipe, caused primarily by friction. While there are also minor losses, such as losses from bends, valves, and entry/exit points, this discussion focuses specifically on the frictional losses in the pipe. These losses are significant for the design and analysis of piping systems.

Examples & Analogies

Think of head loss like the energy lost when walking through a crowded area. Just as you may slow down or bump into people (causing friction) in a busy street, water experiences friction when it flows through a pipe, slowing it down and losing pressure.

Major Pipe Head Loss Calculation

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Major pipe head loss (due to friction):

\[ h_f = \frac{f L V^2}{2 g D} \]

- Here, \( f \) is the friction factor.

- \( L \) is the length of the pipe.

- \( V \) is the velocity of fluid.

- \( g \) is acceleration due to gravity.

- \( D \) is the diameter of the pipe.

Detailed Explanation

This chunk provides the formula used to calculate major head loss due to friction, known as the Darcy-Weisbach equation. It relates the head loss to the fluid properties and the nature of the pipe. Each variable plays an essential role: the friction factor \( f \) represents how much resistance the fluid encounters, while length and velocity reflect how far and how fast the fluid is moving. The equation shows that longer pipes and higher velocities lead to greater head loss.

Examples & Analogies

Imagine pushing a shopping cart through a long aisle in a store. The further you push it, the harder it becomes to move because of the friction between the wheels and the floor. Similarly, in a long pipe, fluid faces resistance the longer it travels, which increases the energy it loses due to friction.

Substituting Values into the Equation

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So once know it then you can compute the pressure. Just substitute the value then compute the pressures. So it is quite easy job now once you know that.

Detailed Explanation

This chunk emphasizes the importance of substituting known values into the Darcy-Weisbach equation to calculate the pressure loss in the system. Once one has the necessary values for friction factor, pipe length, fluid velocity, and pipe diameter, they can easily compute the head loss and consequently the changes in pressure throughout the pipe system. It highlights that this step becomes straightforward with a clear understanding of the equation.

Examples & Analogies

Think of this as baking a cake. Once you have your ingredients measured (like sugar, flour, and eggs), mixing them according to the recipe becomes an easy task. Similarly, substituting values into this equation is like following the steps to complete a simple calculation.

Example Problem for Pressure Calculation

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now you take it the second problems which has the GATE 2015 problems is that the pipe of 0.7 meter diameter has a length of 6 kilometer connects the two reservoirs okay and the water level in the reservoirs is 30 meter above the water level of reservoir B.

Detailed Explanation

This chunk introduces an example problem that applies the concepts learned. It describes a pipe scenario where two reservoirs are connected, one at a higher elevation than the other. By understanding the setup, students can calculate the energy differences involved and apply the formulas to find the head loss due to friction in this specific context. It's a practical application of theoretical knowledge.

Examples & Analogies

Imagine two storage tanks where one tank is much taller than the other. The water would need energy to reach the upper tank, just as the water in the pipe faces energy loss due to friction on its way to the upper reservoir.

Understanding Energy Loss from Head Difference

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So we need to try to know it that how what could be the Q value such way that we will have the energy losses of 30 meters when passing through these 6 kilometer long pipe.

Detailed Explanation

In this section, the focus is on understanding how to calculate the flow rate (Q) to ensure that the energy losses amount to a specific height difference, in this case, 30 meters. It highlights how the elevation difference impacts energy loss calculations and emphasizes the importance of balancing the energy within the system to maintain flow between the reservoirs. The challenge is to maintain a flow that compensates for the combined losses.

Examples & Analogies

Consider riding a bike uphill: the higher you need to go (like the 30-meter difference), the more effort (energy) you must put in to maintain your speed. Similarly, the water must have enough energy to overcome the losses from friction plus the uphill distance.

Key Concepts

-

Head Loss: A measure of energy loss in fluid motion due to friction.

-

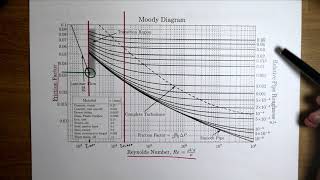

Darcy-Weisbach Equation: Formula for calculating head loss in a piping system.

-

Bernoulli’s Equation: A fundamental principle relating pressure and velocity in fluid flows.

Examples & Applications

Example 1: Calculating head loss for a specific diameter and length of a pipe using the Darcy-Weisbach equation.

Example 2: Application of Bernoulli’s equation to determine pressure changes along a pipeline.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Fluid flows nice and smooth, but with friction, it starts to lose.

Stories

Imagine a river flowing smoothly but, upon reaching obstacles like rocks, it slows down, illustrating how friction affects flow.

Memory Tools

Remember H-L-F for Head Loss due to Friction!

Acronyms

Use D-W for Darcy-Weisbach.

Flash Cards

Glossary

- Head Loss

The reduction in total mechanical energy of the fluid as it moves through a pipe, caused by friction and other factors.

- Minor Losses

Energy losses in a fluid system that occur due to fittings, valves, and bends in pipes, typically expressed as a fraction of the velocity head.

- DarcyWeisbach Equation

An equation used to calculate the head loss due to friction in a pipe, expressed as h_f = f (L/D)(v^2/2g), where f is the friction factor.

- Bernoulli’s Equation

A principle in fluid dynamics that describes the relationship between the pressure, velocity, and height in a flowing fluid.

Reference links

Supplementary resources to enhance your learning experience.