Problem Overview

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Major Head Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we’ll learn about major head losses in fluid mechanics, which primarily relate to friction in the piping system. Can anyone tell me what factors affect these major losses?

Isn’t it the length and diameter of the pipe that matters?

Exactly! The length and diameter of the pipe significantly influence the frictional losses. We can use the Darcy-Weisbach equation to compute these losses. Remember, friction factor is key here.

What happens if the pipe diameter increases?

Good question! An increase in pipe diameter leads to lower friction loss, allowing for a greater flow rate. Can you remember this with the acronym 'LARGE'? It stands for Length Affects Resistance, Generally Easing flow.

Does that mean smaller pipes would have a higher head loss?

Correct! Smaller pipes indeed present higher head loss due to increased frictional resistance. Now, let’s summarize: major losses are primarily impacted by pipe length, diameter, and the flow rate. Always factor these into your calculations.

Explaining Minor Head Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss minor head losses. Can anyone mention the components that contribute to these losses?

Bends and valves?

That's right! Minor losses occur at bends, valves, and other fittings. Although often smaller in magnitude, they can add up. Remember this with the phrase 'BEND-VALVE': Bends and Valves Enact Necessary Drops and Variable Losses in Energy.

So, minor losses are crucial for accurate calculations in systems?

Absolutely! They are necessary for precise modeling and understanding of a fluid's behavior in a system. Failure to account for them can lead to significant errors.

What if we ignore these minor losses?

Ignoring minor losses can lead to an inaccurate prediction of pressure drops and energy efficiency in the system. Final thoughts? Minor head losses must be part of all calculations to prepare effective fluid flow designs.

Applying Bernoulli’s Equation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s look into applying Bernoulli’s equation to compute pressures in a fluid system. Who can summarize the equation?

It relates the kinetic energy, potential energy, and pressure energy in a fluid system.

Correct! Now, can someone explain how we incorporate major and minor losses into the equation?

We subtract the head losses from the total head in the system to find the available energy.

Spot on! This process enables us to accurately predict fluid behavior. Remember the phrase 'PRESSURE-ADJUST': Predicting Real Energy Substituting Stressful Unaccounted Resistance Effects.

What’s the implication of these calculations in real-world scenarios?

In reality, engineers use these calculations to design effective piping systems that can efficiently transport fluids over long distances. In summary, applying Bernoulli’s equation thoughtfully integrates all head losses—major and minor—for practical fluid design.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section elaborates on the computation of head losses in fluid mechanics, focusing on major losses due to friction and minor losses from bends and valves. Detailed examples illustrate the application of Bernoulli's equation to find pressures in fluid systems.

Detailed

Detailed Summary of Problem Overview

This section focuses on the concept of head losses in fluid mechanics, crucial for understanding how fluids behave in pipes and other conduits. It begins by explaining major head losses, which result from friction within the fluid flowing through pipes. A fundamental equation is provided for calculating major head loss based on parameters such as flow rate and pipe characteristics.

The discussion transitions into minor head losses, which occur at bends, valves, and junctions in the fluid system. The text specifies that while entry and exit losses are not considered in this instance, bend and valve losses are included in the calculations.

Utilizing Bernoulli’s equation, the calculations allow for determining the pressure in various points of the system, revealing how energy is conserved within flowing fluids. Several practical examples enhance the reader's comprehension of these concepts, revealing the importance of knowing both major and minor head losses when designing and analyzing fluid systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Head Losses

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So that means I know the head losses that is what is computed here by substituting this value. There will be minor losses like bend losses, valve losses, the entry and exit losses all the components, this entry and exit loss we do not consider it here only the bend loss and valve loss we compute it which we have these values.

Detailed Explanation

Head losses in fluid dynamics refer to the loss of pressure due to friction and other factors as fluid flows through a pipe. In the provided content, the focus is placed on two types of losses: minor losses and major losses. Minor losses occur from changes in the flow direction or cross-sectional area, such as bends or valves. The text indicates that only the losses from bends and valves are computed, while entry and exit losses are ignored for this analysis.

Examples & Analogies

Imagine water flowing through a hose. If you bend the hose sharply or add a nozzle (like a valve), the water doesn’t flow as freely, which creates resistance or 'head loss.' Think of it as trying to sip juice through a straw; if the straw bends sharply, it becomes harder to drink quickly.

Major Pipe Head Loss

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Major pipe head loss (due to friction): Major pipe head loss is computed using specific values and formulas that calculate the amount of head loss caused by friction within the pipe. There are no further calculations detailed here, but the values are stated.

Detailed Explanation

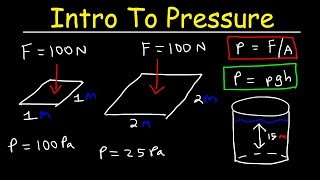

Major head loss occurs mainly due to friction when fluid moves through a pipe. It can be calculated using equations like the Darcy-Weisbach equation, which incorporates factors like the pipe's length, diameter, and the fluid's velocity. The text suggests that specific values for these parameters are used to calculate the friction head loss, indicating it is a systematic procedure based on measured or estimated values.

Examples & Analogies

Think about water running down a long, skinny slide. The longer the slide, the more friction the water experiences, which slows it down. In practical terms, if the slide is rough or twisted, the water takes even longer to reach the bottom, much like how fluid loses energy when moving through knee bends or experiencing rough surfaces in pipes.

Minor Losses

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Minor losses: If are considering that the loss components will get it this much is the minor losses.

Detailed Explanation

Minor losses represent the additional head losses due to fittings, bends, and valves that occur in a piping system. These losses may seem small compared to the major losses caused by friction but can accumulate, especially in complex systems. The text implies that these minor losses need to be accounted for to get a complete picture of the total head loss in a system.

Examples & Analogies

When driving a car, every turn or stop requires energy; even small detours can add up to significant delays. Similarly, small adjustments in flow paths within a piping system lead to minor losses, which, though individually small, can compromise overall system efficiency when combined.

Calculating Pressure Using Bernoulli's Equation

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now we are substituting Bernoulli’s equations, the modified Bernoulli’s equations to compute what could be the pressure. So I am not going more detail as you can read this ppt to get these details.

Detailed Explanation

Bernoulli’s equation relates the pressure, velocity, and height in a fluid system and is essential for understanding how energy is conserved in flowing fluids. In this portion, the speaker indicates that by substituting known values into the modified Bernoulli’s equation, one can calculate the pressure at various points in the system. This step is critical in hydraulic engineering, as it allows for the design of pipes that function efficiently and meet safety standards.

Examples & Analogies

Imagine a water bottle with a long straw. If you cover the top of the straw and suck from the bottom, the water rises due to lower pressure at the top. Just as you can calculate the pressure at different heights in the straw, engineers can calculate the pressure at various points in a pipe system using Bernoulli’s equation, aiding in predicting fluid behavior accurately.

Practical Problem Illustration

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

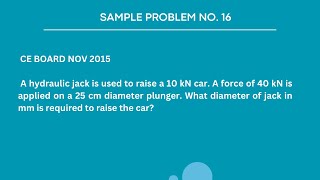

Now you take it the second problems which has the GATE 2015 problems is that the pipe of 0.7 meter diameter has a length of 6 kilometer connects the two reservoirs ...

Detailed Explanation

The section introduces a specific problem involving a pipeline that connects two reservoirs separated by an elevation difference. This problem emphasizes the calculations needed to find out how much water can be delivered while accounting for losses through friction and other minor losses. Particular values are listed, and students are encouraged to visualize the system to understand the flow dynamics involved better.

Examples & Analogies

Think of the problem as a long, winding water slide that begins high up and ends in a lower pool. Just as you would need to calculate the water flow and any potential slowdowns due to twists and turns on the slide, engineers must evaluate how water moves through the pipes, how much energy is lost, and ultimately how much water can splash into the pool at the end.

Key Concepts

-

Major Head Loss: Loss of pressure due to friction in the pipes.

-

Minor Head Loss: Losses due to fittings, valves, and bends.

-

Friction Factor: Key variable affecting head loss calculations.

-

Bernoulli’s Equation: A tool for determining fluid pressures and energy across systems.

Examples & Applications

Example calculating the pressure drop due to friction in a 100-meter long pipe with a diameter of 0.5 meters.

Example finding the required pressure at a valve to maintain a specified flow rate in a piping system.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Frictions high in small pipes' flow, major losses we come to know.

Stories

Imagine a fluid racing through a winding path; it loses energy at every turn and valve—each causing minor losses that add up.

Memory Tools

LARGE for major losses: Length Affects Resistance, Generally Easing flow.

Acronyms

BEND-VALVE

Bends and Valves Enact Necessary Drops and Variable Losses in Energy.

Flash Cards

Glossary

- Major Head Loss

Loss of pressure due to friction in a pipe, which is calculated using specific formulas.

- Minor Head Loss

Loss of pressure that occurs at devices such as fittings and valves in a fluid system.

- Bernoulli's Equation

A principle that relates a fluid's pressure, velocity, and height, allowing for energy calculations in fluid dynamics.

- Friction Factor

A dimensionless number used to calculate the resistance to flow in a fluid system due to internal friction.

Reference links

Supplementary resources to enhance your learning experience.